Ingersoll-Rand 301: инструкция

Раздел: Инструмент, электроинструмент, силовая техника

Тип:

Инструкция к Ingersoll-Rand 301

16573487

Edition 6

July 2006

Air Die Grinder

301, 301-EU, 307A, 307A-EU, 308A, 308A-EU,

3102, 3102-EU, 3107G, 3108 and 3108-EU

Product Information

EN

Product Information

SL

Specikacije izdelka

ES

Especicaciones del producto

SK

Špecikácie produktu

FR

Spécications du produit

CS

Specikace výrobku

IT

Speciche prodotto

ET

Toote spetsikatsioon

DE

Technische Produktdaten

HU

A termék jellemzői

NL

Productspecicaties

LT

Gaminio techniniai duomenys

DA

Produktspecikationer

LV

Ierices specikacijas

SV

Produktspecikationer

PL

Dane techniczne narzędzia Rozmiar

NO

Produktspesikasjoner

RU

Технические характеристики изделия

FI

Tuote-erittely

ZH

产品信息

PT

Especicações do Produto

JA

製品仕様

EL

Προδιαγραφές προϊόντος

KO

제품 상세

Save These Instructions

2 16573487_ed6

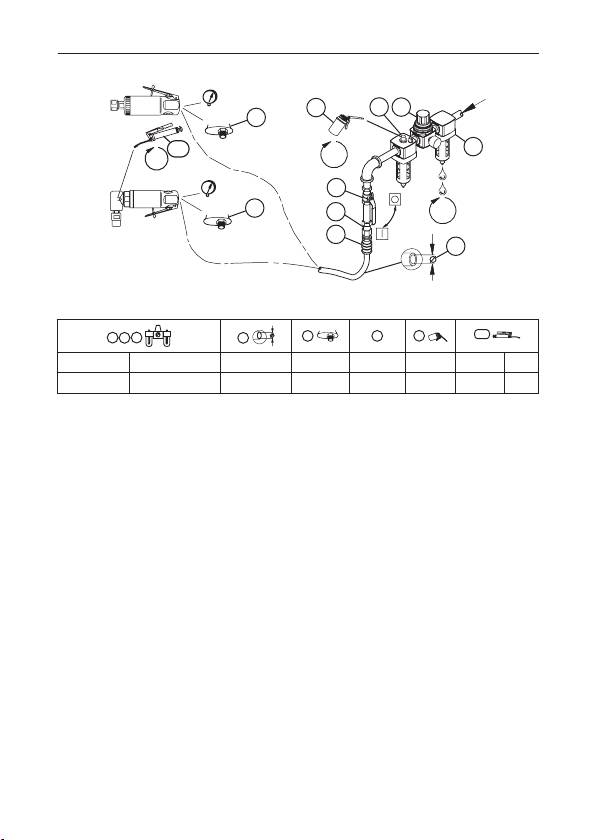

PMAX

9

3

2

6

10

1

48h

8h

PMAX

4

6

24h

8

7

5

(Dwg.16573164)

1

2

3

5

6

7

9

10

3

I-R # - NPT I-R # - BS inch (mm) NPT I-R # I-R # I-R # cm

C241-810 C28241-810-B 3/8 (10) 1/4 MSCF32 10 67 2

EN

Product Safety Information

Intended Use:

These die grinders are designed for grinding, porting, polishing, de-burring, and breaking

sharp edges.

For additional information refer to Air Die Grinder Product Safety Information Manual

Form 04580288.

Manuals can be downloaded from www.irtools.com.

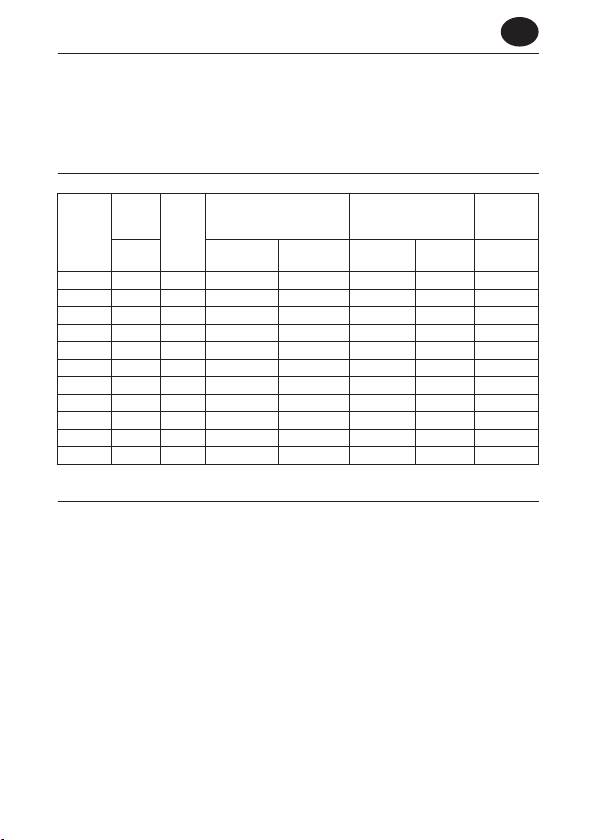

Product Specications

Vibration

Free

Sound Level dB (A)

Sound Level dB (A)

Level

Speed

Collet

(ISO15744)

(ANSI S5.1-1971)

Model(s)

(ISO8662)

Size

† Pressure

Power

rpm

‡ Power (L

) Pressure

m/s²

w

(L

)

(ISO3744)

p

301 20,000 1/4” --- --- 91.8 104.8 3.3

301-EU 20,000 6 mm --- --- 91.8 104.8 3.3

307A 27,000 1/4” 83.0 94.0 --- --- 4.9

307A-EU 27,000 6 mm 83.0 94.0 --- --- 4.9

308A 25,000 1/4” 91.0 102.0 --- --- 4.0

308A-EU 25,000 6 mm 91.0 102.0 --- --- 4.0

3102 20,000 1/4” 90.0 101.0 --- --- 2.5

3102-EU 20,000 6 mm 90.0 101.0 --- --- 2.5

3107G 27,000 1/4” 92.4 103.4 --- --- 2.6

3108 25,000 1/4” 92.0 103.0 --- --- 3.4

3108-EU 25,000 6 mm 92.0 103.0 --- --- 3.4

† K

= 3dB measurement uncertanity

pA

‡ K

= 3dB measurement uncertanity

wA

Installation and Lubrication

Size air supply line to ensure tool’s maximum operating pressure (PMAX) at tool inlet. Drain

condensate from valve(s) at low point(s) of piping, air lter and compressor tank daily. Install a

properly sized Safety Air Fuse upstream of hose and use an anti-whip device across any hose

coupling without internal shut-o, to prevent hose whipping if a hose fails or coupling discon-

nects. See drawing 16573164 and table on page 2. Maintenance frequency is shown in circular

arrow and dened as h=hours, d=days, and m=months. Items identied as:

1. Air lter 6. Thread size

2. Regulator 7. Coupling

3. Lubricator 8. Safety Air Fuse

4. Emergency shut-o valve 9. Oil

5. Hose diameter 10. Grease - through tting

16573487_ed6 EN-1