Alexika RV 10 control V-C auto – page 3

Manual for Alexika RV 10 control V-C auto

41

•

Unpacking

- Please unpack the device carefully

- In the case of any damage a fact report must be sent immediately

(post, rail or forwarder)

•

Delivery scope

see table

Useful information

The device is equipped with a piston-operated safety mechanism. The

glass apparatus may contain a vacuum following interruption to the po-

wer supply; vent the system before switching back on. If the power cuts

out, the evaporator piston is automatically lifted out of the heating bath

by an integrated gas spring.

CAUTION!

The safety lift must be checked daily prior to operation. For

more information see the section entitled "Safety Instructions - Safety

Lift"!

In addition to offering a full range of manual and semi-automatic evapo-

ration operating modes, the RV 10 control rotary evaporator can also be

used for fully automatic and quantity-controlled evaporation processes.

Standard fittings for fully-automatic operation include a vacuum cont-

roller, a cooling water differential temperature measurement sensor and

a cooling water flow rate meter. The vacuum can be controlled in both

two-position and speed-controlled pumping operation with the help of

the integrated vacuum controller The device is designed for operation

with a cooling water supply system (e.g. laboratory thermostat), but can

also be run off a water supply line. Please refer to the Technical Data for

information on cooling water pressure, temperature constancy, flow rate

and local regulations.

We recommend using the RV 10.5001 water regulator valve when ope-

rating directly off a water supply line.

This valve allows the cooling water flow rate to be adjusted and automa-

tically cuts off the cooling water supply on completion of the distillation

process.

The RV 10.5002 water filter can be used to prevent particles of dirt pas-

sing from the water supply line into the valve mechanism.

If pressure reduction is required, we recommend fitting the RV 10.5003

pressure regulator valve in the pipe immediately downstream of the pick-

off point.

Automatic volume-dependent distillation:

The apparatus must be

brought up to operating temperature. This is achieved by conducting a

test distillation.

Distillation is a thermal separating process for liquid compounds based

on substance-specific, pressure-dependent boiling points through evapo-

ration and subsequent condensation.

The boiling point temperature decreases with decreasing external pressu-

re which means that work is usually done under reduced pressure. In this

way the heating bath can be maintained at a constant temperature (e.g.

60 °C). Using the vacuum, the boiling point is set with a steam tempe-

rature of approx. 40 °C. The cooling water for the condensation cooler

should not be warmer than 20 °C (60-40-20 rule).

A chemical resistant membrane pump with a vacuum controller should

be used to create the vacuum. The pump is protected from solvent resi-

due by the addition of a Woulff bottle and/or a vacuum separator.

Working with a jet pump to create a vacuum can only be recommended

to a limited extent as the solvents may contaminate the environment

when using these systems.

Speed, temperature, piston size and system pressure all affect the eva-

porator air capacity.

The optimum capacity of the flow-through condenser is approx. 60%.

This corresponds to condensation on approx. 2/3 of the cooling coil.

With larger capacities there is the risk that the uncondensed solvent va-

pour will be extracted.

In order to prevent this, the condenser loading safety monitoring system

can be activated. Before activating the safety monitoring, first carry out

several distillations, noting the value given under menu “Settings”, menu

option “Drive”, item “Maximum heat rejection rate”. Now calculate the

heat rejection rate using the following formula:

Heat rejection rate threshold = maximum heat rejection rate * 1.3

Enter this value under menu “Settings”, menu option “Distillation”, item

“Heat rejection rate threshold”. The device will now stop the measure-

ment and issue an error message if the threshold for the condenser is

exceeded. If the configuration of the condenser equipment or the dis-

tillation process is modified, then it may be necessary to re-evaluate the

maximum condenser loading.

The factory setting for this value is 900 W.

Unpacking

RV

10

control

V

x x x x x x x x x x x x

RV

10

control

V-C x x x x x x x x x x x x

RV

10

control

FLEX x x x x x x x x x x x

RV

10

control

V

auto x x x x x x x x x x x x

RV

10

control

V-C

auto x x x x x x x x x x x x

RV

10

control

FLEX

auto x x x x x x x x x x x

Drive RV 10 contr

ol

Heating bath HB 10

Vertical glasswar

e RV 10.1

Vertical glasswar

e RV 10.10 coated

W

oulff bottle

Br

acket

Cooler locking device, compl.

Vacuum hose (2 x 0.55 m)

W

ater dischar

ge hose (1 x 1 m)

Oper

ating instructions

Ring spanner

Hand

hold

RV 10.4002 vacuum valve for labor

atory vacuum system

N 920 speed-contr

ol

led vacuum pump

42

The RV 10 control rotary evaporator allows you to set the desired vacuum using two-position and speed control with the help of the integrated va-

cuum controller and pressure sensor.

Two-position control

A vacuum is made in the glassware with the help of a vacuum pump. The vacuum pump operates at constant speed which generally cannot be ad-

justed. Once the target value setting is reached, the RV 10.4002 vacuum valve interrupts the suction line (included in scope of supply). If additional

switching on and off of the vacuum pump is desired, please use the RV 10.4003 pump control (accessory).

The device will fall slightly short of the target value setting due to the time difference in the millisecond range with the vacuum value, the target value

comparison and the switching of the vacuum valve. Natural leakage from the apparatus now causes another increase in the pressure value of the

system, which in turn is detected by the integrated pressure sensor.

If the target value is exceeded, the vacuum valve is reopened and the vacuum pump in operation lowers the pressure. The pressure curve shown on

the display fluctuates around the set target value.

The pressure difference between activating/deactivating the valve can be set using the vacuum hysteresis value (see Vacuum Settings). The value is set

to 10 mbar as standard.

The quality of the control depends on the suction power of the pump (rotation speed), the tightness of the system and signal delay time of the elec-

tronics used.

Automatic boiling point recognition is not possible when using two-position control.

Schematic view of a two-position vacuum control

Speed-vacuum control

Imprecision of the two-position control is avoided by using the speed-vacuum control.

However a vacuum pump with a controlled speed is needed for speed-vacuum control; the RV10.4002 vacuum valve is not required and must not

be connected!

To do so, connect the vacuum pump (e.g. KNF N920 speed controlled pump) to the port on the rear of the rotary evaporator.

With this kind of control, the speed of the pump, and therefore its suction power, is reduced the closer the measured pressure reaches the target value.

Once the target value is reached, the pump only operates according to the leakage rate.

It is possible to achieve quieter operation and more exact vacuum control.

The speed-vacuum control on the RV 10 is controlled automatically as soon as an appropriate vacuum pump is attached.

Automatic boiling point recognition is possible with this type of control, i.e. the system reaches and keeps the solvent at its boiling point in automatic

mode.

As it is not necessary to know the boiling point of the solvent when in automatic boiling point recognition mode (unlike in the case of volume-depen-

dent distillation), these two operating modes are mutually exclusive.

Schematic view of speed-vacuum control

Vacuum control: two-position and speed control

43

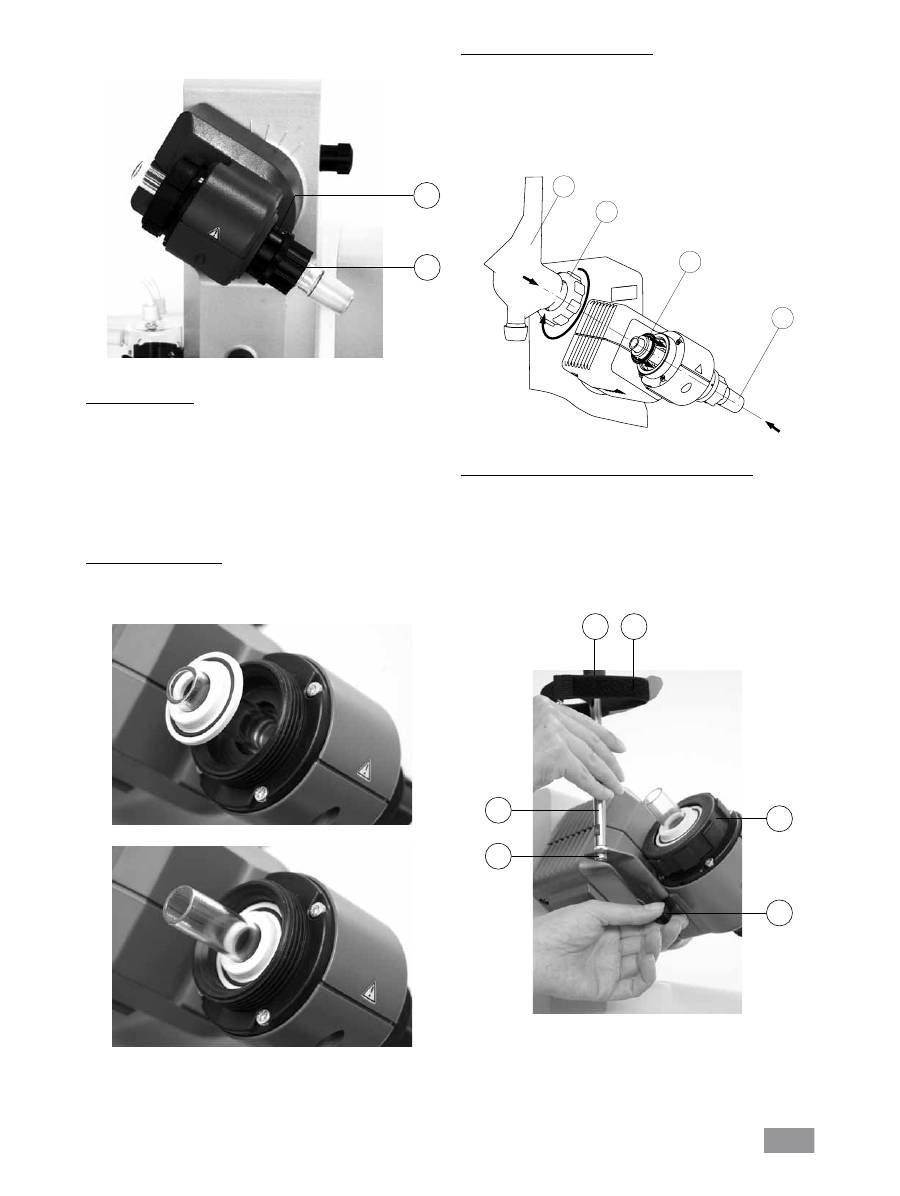

Setting up

Remove the clamping device for the angle setting of the rotation drive

on the right side of the lift by rotating the knurled screw counter clock-

wise (by lightly pressing and turning at the same time, the knurled

screw comes out farther).

Set the drive at an angle of approx. 30° (Fig. 7).

Then secure the rotation drive from being accidentally turned by tigh-

tening the knurled screw in a clockwise direction.

Heating bath HB 10

Caution!

Refer to the chapter entitled "Commissioning" in the heating

bath instruction manual!

Place the heating bath on the stand of the rotation drive and push it

into the left position (Fig. 8).

Note: Data is exchanged between the drive unit and the heating bath by

means of an infrared link (F). Please note that reliable communication is

only guaranteed when the infrared beam has clear line-of-sight to the

detector.

Glassware

Open the locking device of the steam pipe by turning it 60° counter

clockwise (D), (fig. 9).

Drive RV 10 control

Caution!

Loosen transportation lock (Fig. 4a)!

Hold the lift with your hand and remove the thumb screw on the back

of the appliance (A).

Once the transportation lock has been removed, the lift moves slowly

to its upper end position. The distance is approx. 140 mm.

Connect the device to the power supply (B) using the supplied power

cord (B).

Adjustable base (Fig. 4b)

Mounting the Woulff bottle (Fig. 5)

Fit the hose connecting piece (C) on the left side of the lift.

Mount the holder (D) onto the hose connecting piece (C).

Insert the bottle and attach the supplied hose connectors to the bottle

(Fig. 6).

Fig. 4a

Fig. 4b

E

G

H

Fig. 7

Fig. 9

Fig. 5

Fig. 6

C

D

Fig. 8

F

44

First use - Fitting the seal RV 10.8001

Insert vapour tube (1).

Insert seal RV 10.8001 (2).

Slide the union nut (3b) over the flange on the condenser (3a).

Also slide the annular spring (3c) over the flange on the condenser (3a).

Position the condenser (3a) on top of the seal (2).

Tighten the cap nut hand-screwed (3b).

Note: Follow the mounting instructions for the glassware

Assembling the vertical glassware cooler locking device

Assemble the condenser locking device according to the diagram (fig.

12).

Mount the plate (I) using the thumb screw (J).

Put the support rod (L) on the plate (I) and attach it with the screw

nut (K).

Attach the rubber protector (M).

Fasten the Velcro

®

band (N) to the support rod (L).

Secure the vertical glassware with the Velcro

®

band (N).

Feed the steam pipe in until it stops.

Then lock the locking device by turning it clockwise by 60° (Fig. 10).

Check the axial locking device on the steam pipe.

Push-off mechanism

The plastic screw nut (H) helps loosen tight-fitting piston ground-in con-

nections (Fig. 10).

Hold the locking device (G) and loosen the plastic screw nut (H).

To do so, hold the tight-fitting evaporator piston and turn the plastic

screw nut (H) until the evaporator piston neck.

Note: Prior to commissioning, hand-tighten the plastic screw nut (H) left-

aligned. This will hold the steam pipe locking device (G) firmly in place.

Fitting the condenser seal

Place the RV 10.8001 condenser seal in the condenser receptacle and

fit the glassware to the device according to the assembly instructions

(Fig. 11 a,b, c and d).

Fig. 10

H

Fig. 11a

Fig. 11b

1

2

3a

3b

Fig. 11c

Fig. 12

I

J

M

N

L

K

G

45

4

7

8

6

12

9

3

10

5

13

15

16

Rotary head

Glassware

RV 10.2 diagonal

RV 10.20 diagonal, coated

Glassware

RV 10.1 vertical

RV 10.10 vertical, coated

Rotary head

2

10

00

m

l

N

S2

9/

32

1

11

13

12

5

4

7

8

6

15

9

3

2

10

16

11

1

10

00

m

l

N

S2

9/

32

Glassware

Item Designation

Quantity

Quantity

diagonal glassware

vertical Glassware

1

Receiving flask

1

1

2

Clamp NS 29 (stainless steel)

1

1

3

Steam pipe

1

1

4 Stopcock

1

1

5

Pipe tube

1

1

6

Condenser

1 Diagonal condenser

1 Vertical condenser

7

Connection

1 Introduction sleeve

1 Vacuum connection

8

Clamp NS 29 (plastic)

1

1

9

Seal RV 10.8001

1

1

10

Evaporator piston 1000 ml

1

1

11

Ball joint clamp RV 05.10

1

1

12

Screw joint cap

4

4

13

Hose connection

4

4

15

Locking nut

1

1

16

Spring ring

1

1

Description of special condensers

•

RV 10.3 Vertical-intensive condenser with manifold

This vertical-intensive condenser features a double jacket design for

particularly efficient condensation.

Also available with coating (RV 10.30)

•

RV 10.4 Dry ice condenser

Dry ice condenser for distilling low-boiling solvents.

Cooling by dry ice, no cooling water required. Maximum condensation

thanks to low temperatures.

Also available with coating (RV 10.40)

(Cannot be used in automatic mode for the RV10 control)

•

RV 10.5 Vertical-condenser with manifold and cut-off valve for

reflux distillation

Also available with coating (RV 10.50)

•

RV 10.6 Vertical-intensive condenser with manifold and cut-off

valve for reflux distillation

This vertical-intensive action condenser features a double jacket design

for particularly efficient reflux distillation.

Also available with coating (RV 10.60)

Removing the condenser

Use the ring spanner provided to loosen union nuts that are tightly

fitted.

Loosen the union nut by turning anticlockwise.

Remove the Velcro

®

.

Fig. 13

Mounting the glassware

46

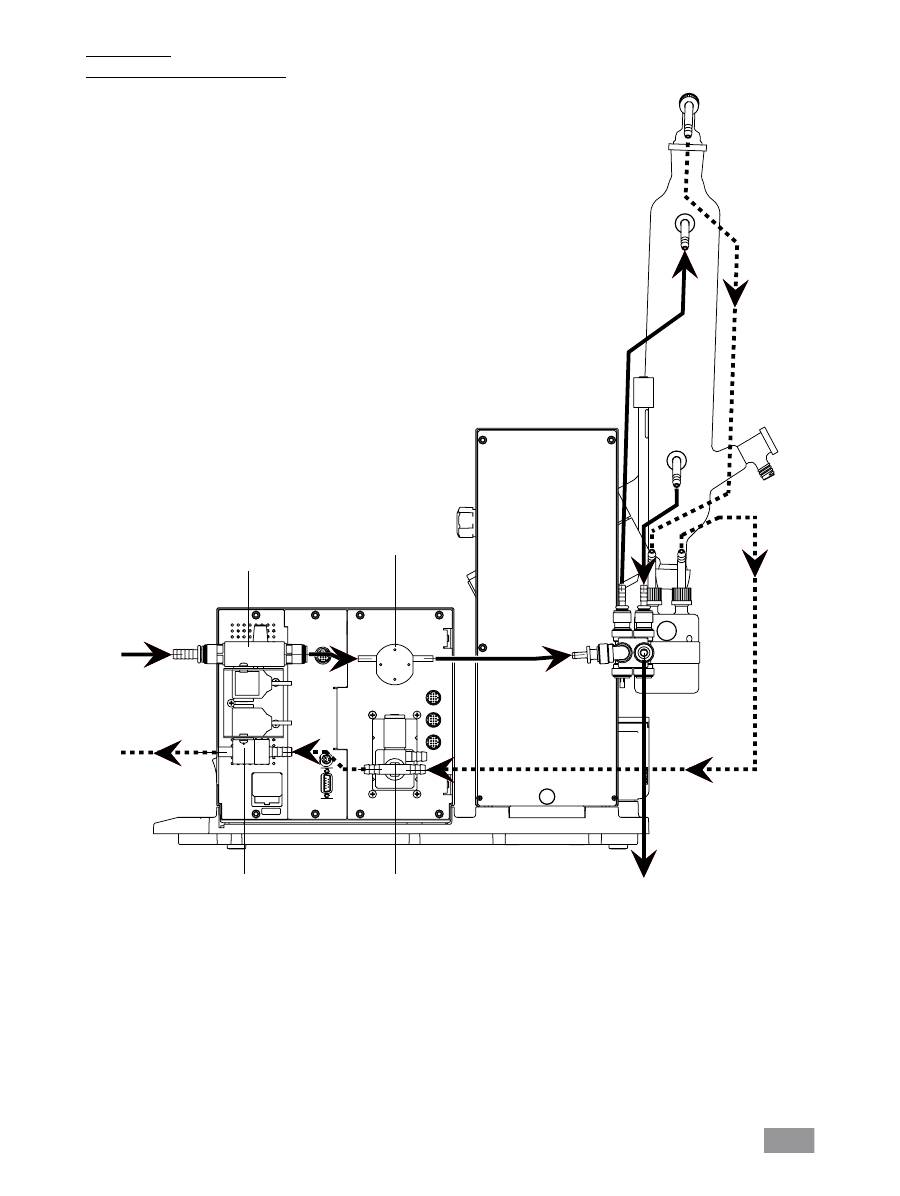

Hose system

Schematic view of hose system (rear view)

2x T1,6A 250V

Water

Vacuum

RV 10.5001

Water regulator

valve,

optional

Flow meter

Water

Pressure sensor

and

bleed valve

RV 10.4002

Vacuum valve

Fig. 14

47

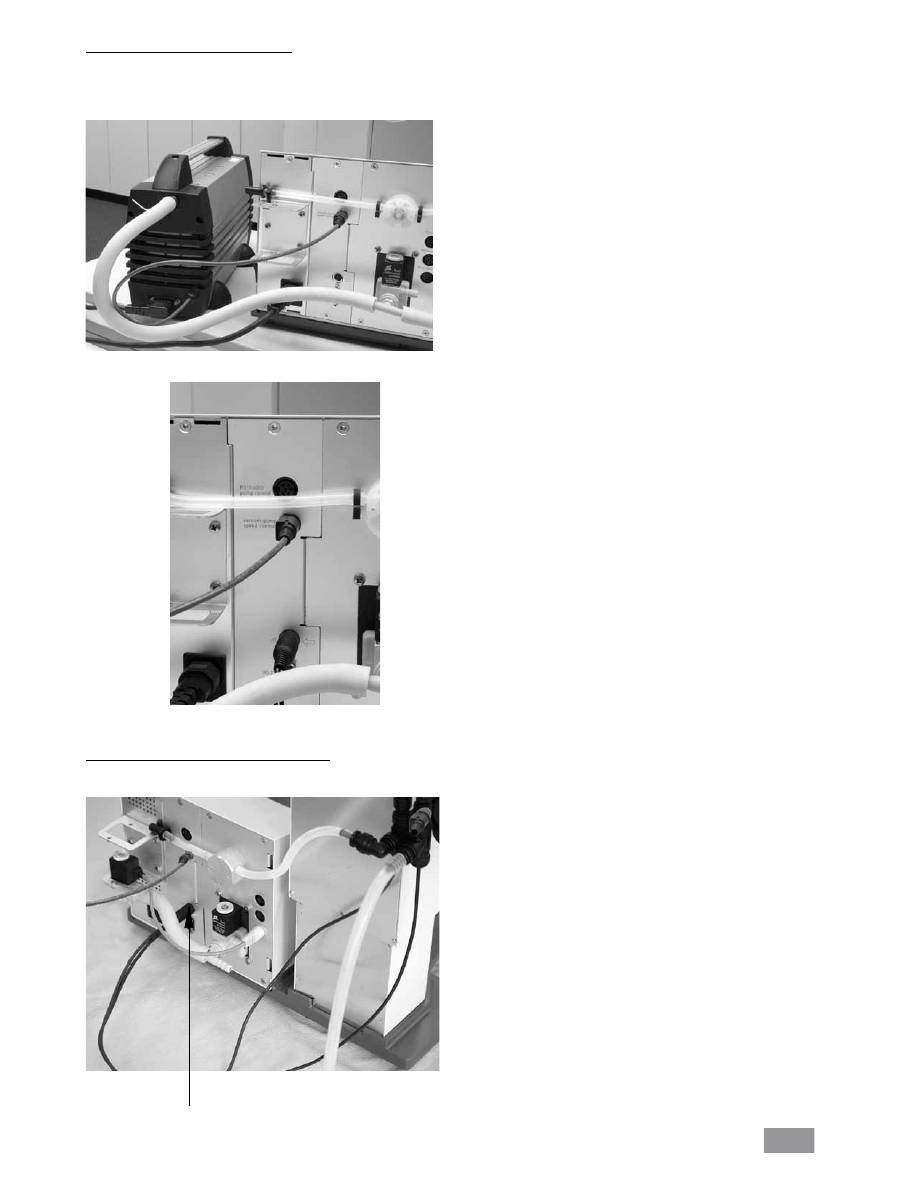

Connection RV 10.4003

Vacuum - two-position control

Fit one of the optional RV 10.4001, RV 10.4002 or RV1 0.4003 vacu-

um valves, as appropriate for the type of vacuum system used, in the

bracket provided for this purpose and connect the vacuum hose to the

valve (Figure 15a, b, c).

Connection RV 10.4001

Connection RV 10.4002

Solenoid rotates freely

Direction of suction

corresponds to the arrow

marking.

Always check for correct

orientation!

Fig. 15a

Solenoid rotates freely

Direction of suction

corresponds to the arrow

marking.

Always check for correct

orientation!

Fig. 15b

Solenoid rotates freely

Direction of suction

corresponds to the arrow

marking.

Always check for correct

orientation!

Fig. 15c

Power supply

pump

48

Vacuum - speed-controlled operation

No additional valve is required for vacuum normal operation with a

speed-controlled pump. Connect the pump's vacuum hose directly to

the pressure sensor hose connection.

Connect the electrical RV10 control cable to the controller (Fig. 15e).

Connection RV 10 temperature sensor ( (dT)

Connect the temperature sensor to the lower socket (dT). Always check

for correct direction of the arrow.

Fig. 15f

dT

Fig. 15d

Fig. 15e

49

Connect the water outlet hose (supplied) by pushing it onto the nipple

until the stop inside the connection socket is reached (fig. 18).

Caution!

Ensure that the condenser inlet and condenser outlet are con-

nected correctly.

Automatic distillation cannot be carried out if the water inlet and outlet

hoses are not fitted according to the instructions and illustrations acc.

fig. 14, since this would cause the temperature readings for the inlet and

outlet to be measured incorrectly.

Release the hose connection using the supplied tool.

Water

Connect the water inlet to the water supply (Figure 16a; Figure 16b with

optional RV 10.5001 water regulator valve). Please refer to the technical

specifications relating to the water supply.

The RV 10.5001 water regulator valve is not suitable for use on the

condenser unit because it would reduce the flow rate too greatly

Connect the water hoses to the glass condenser (short hose (O) = lower

outlet, long hose (P) = upper inlet) and fix hoses in place (fig. 17).

Note: For special condensers see “Description of special condensers” section.

Fig. 16a

Fig. 16b

Fig. 17

O

P

Fig. 18

Fig. 19

Inlet

condenser

Outlet

condenser

Water

inlet

Water

inlet

50

Schematic view of connections (rear view)

Insert the valve connector cable (RV 10.5001 or RV 10.4001/2 resp. RV 10.4003 Valve) resp. the network cable (RV 10.4003 pump control) ) into the

appropriate socket (fig. 20) or connect the speed-regulated vacuum pump. As a result, the RV10 control automatically switches to normal speed-vacuum

control operation.

Fig. 20

Connect the pressure sensor to the Woulff bottle and the Woulff bottle

to the vacuum connector on the condenser using the vacuum hoses

supplied. Please note that the vacuum must always be connected to the

highest connection point on the condenser (fig. 21).

Fig. 21

51

Serial interface RS 232 (V24)

Configuration

- The functions of the interface lines between the device and the au-

tomation system are a selection from the signals specified in the EIA

standard RS232 C, as per DIN 66 020 Part 1.

- For the electrical characteristics of the interface and the allocation of

signal status, standard RS 232 C applies in accordance with DIN 66

259 part 1.

- Transmission procedure: asynchronous character transmission in start-

stop mode.

- Type of transmission: full duplex.

- Character format: character representation in accordance with data for-

mat in DIN 66 022 for start-stop mode. 1 start bit; 7 character bits; 1

parity bit (even); 1 stop bit.

- Transmission speed: 9600 bit/s.

- Data flow control: none

- Access procedure: data transfer from the device to the computer takes

place only at the computer’s request.

Command syntax and format

The following applies to the command set:

- Commands are generally sent from the computer (Master) to the device

(Slave).

- The Rotary evaporator sends only at the computer’s request. Even fault

indications cannot be sent spontaneously from the Rotary evaporator to

the computer (automation system).

- Commands are transmitted in capital letters.

- Commands and parameters including successive parameters are separa-

ted by at least one space (Code: hex 0x20).

- Each individual command (incl. parameters and data) and each response

are terminated with Blank CR LF (Code: hex 0x20 hex 0x0d hex 0x20 hex

0x0A) and have a maximum length of 80 characters.

- The decimal separator in a number is a dot (Code: hex 0X20E).

The above details correspond as far as possible to the recommendations

of the NAMUR working party (NAMUR recommendations for the design of

electrical plug connections for analogue and digital signal transmission on

individual items of laboratory control equipment, rev. 1.1).

The NAMUR commands and the additional specific

IKA

®

co mmands serve

only as low level commands for communication between the rotary eva-

porator and the PC. With a suitable terminal or communications program-

me these commands can be transmitted directly to the rotary evaporator.

The

IKA

®

software package, labworldsoft, provides a convenient tool for

controlling rotary evaporator and collecting data under MS Windows, and

includes graphical entry features, for motor speed ramps for example.

The following table summarises the (NAMUR) commands understood by

the

IKA

®

control equipment.

HB 10

Data is exchanged between the heating bath and the drive unit by means

of an infrared link. These are located on the left display side of the hea-

ting bath or on the right side of the drive unit. Do not place any objects

between the two operating units as otherwise the data transfer may be

interrupted (fig. 22)!

RV10 control

The device can be operated in “Remote” mode via an RS 232 or USB

interface using labworldsoft

®

laboratory software.

The RS 232 interface at the back of the device, see fig. 20, is fitted with

a 9-pole SUB-D jack and can be connected to a PC. The pins have serial

signals. The USB interface is located on the left-hand side of the display

on the drive unit and can be connected to a PC using the USB cable

supplied.

Note: Please note the system requirements as well as the operating ins-

tructions and help section included with the software.

USB Interface

The Universal Serial Bus (USB) is a serial bus system used to connect the

RV 10 control with the PC (Fig. 23). Devices that support USB can be con-

nected to each other whilst they are running (hot pluggable) and provide

automatic recognition of the connected devices and their properties.

Use the USB interface in conjunction with labworldsoft

®

for operation in

“Remote” mode to update the solvent library. Navigate to http://www.

ika.net/ika/lws/download/RV10.cfg to update.

Installation

Connect the RV 10 control to the PC using the USB data cable. The RV 10

control will then transmit information to the Windows operating system

to tell it which device drivers are required. Windows will then either:

- Load the driver,

- Install the driver automatically if not already installed,

- Prompt the user to perform a manual installation.

Navigate to http://www.ika.net/ika/lws/download/stmcdc.inf.

Interfaces and outputs

Fig. 22

IR

Fig. 23

52

Fig. 24

Abbreviations used:

m =

Numbering parameter (integer)

X =

2

Temperature heating bath

X =

3

Safety temperature heating bath

X =

4

Speed

X =

60

Interval time (1-99 seconds, 1 <= m >=99)

X =

61

Timer (1-199 minutes, 1 <= m >=199)

X =

62

Upper lift position (OUT_SP_62 1-> drive lift up)

X =

63

Lower lift position (OUT_SP_62 1-> drive lift down)

X =

66

Value vacuum controller

X =

70

Vacuum controller hysteresis

X =

74

Tempering medium (OUT_SP_74 0=Öl, OUT_SP_74 1=water)

NAMUR Commands Function

IN_NAME

Request designation

IN_PV_X

Read actual value

X = 4

IN_SOFTWARE

Request software Id-number,

date and version

IN_SP_X

Read target value input

X = 4

OUT_SP_X m

Set target value to m

X = 1,60,61,62

RESET

Switch to normal operation

START_X

Switch on appliance (remote) function

X = 4,60,61,62

STATUS

Status output

0:Manual operation without interruption

1:Automatic operation Start (without interruption)

ERROR z (z error number see table)

STOP_X

Switch off appliance function. The variable

X = 1,60, 61, 62

set with OUT_SP_X remains

PC 1.1 Cable (Fig. 24)

This cable is required to connect the 9-pin connector to a PC. (fig. 24).

.

53

Basic guide to using the menu system

Selecting a menu

Turn the Rotating/ Pressing knob to the right/left to select the desired

menu option.

Note: The active menu item is shown with a black background on the

display.

Editing values

Press the Rotating/ Pressing knob

Turn the Rotating/ Pressing knob to change the value (the magnitude

of the change is dependent on the speed at which the knob is turned).

Press the Rotating/ Pressing knob again to complete the process.

Exiting a menu

Press the SET button.

Current values are stored.

Next-highest menu level is displayed.

Press the ESC button.

Current values are not stored.

Next-highest menu level is displayed.

Note: Some menu items do not contain values that can be stored. Select

SET or ESC to exit the menu.

Note: Certain menu items have functionality that varies from or adds to

that described above.

Display screen during the distillation process

Each operating mode has its own dedicated display screen. The following

display characteristics are common:

- When a distillation is in progress it is not possible to leave the active

display indicated.

- Press SET or ESC to exit the active display mode when no distillation is in

progress. This will return the display to the main menu.

Error messages

Press ESC to acknowledge the fault if an error message appears on

the display.

The error message will disappear.

Note: In the case of serious faults, an additional display message will

appear indicating that the device must be switched off and only swit-

ched back on again when the fault has been rectified.

The unit is ready for service when the

mains plug has been plugged in.

Switching on the device

Switch on the device on the right side of the device by the mains plug

(fig.25).

Device functions activated.

Note: The heating bath must also be switched on.

Commissioning

Functional description (in as-delivered state)

Factory settings

The values specified below correspond to the as-delivered state (display

output/factory language setting is English)

The system check is performed while the start screen is displayed; this

takes no more than 30 seconds.

The main menu will appear after a few seconds.

Turn the Rotating/ Pressing knob to the right/left to select a menu

option.

Confirm the selection by pressing the Rotating/ Pressing knob.

“Settings“ menu

The following options are available from the "Settings" menu.

Turn the Rotating/ Pressing knob to the right/left to select a menu

option.

Confirm the selection by pressing the Rotating/ Pressing knob.

Fig. 25

54

Distillation settings

Turn the Rotating/ Pressing knob to the right/left to select a menu

option.

Press the Rotating/ Pressing knob.

Turn the Rotating/ Pressing knob to change the value (the magnitude

of the change is dependent on the speed at which the knob is turned).

Press the Rotating/ Pressing knob again to complete the process.

SET key: Exit menu and save changes.

ESC key: Exit menu without saving changes.

Distillation method

Select between the automatic distillation methods “Volume” and

“100%”. This selection only has an effect during auto-distillation.

Volume

The measured values of the cooling water flow rate and the cooling

water temperature difference form the basis for a heat balance calcu-

lation used to determine the quantity of distillate at every stage of the

distillation. The distillation process is halted when the specified quantity

of distillate has been reached.

100%

The distillation process is stopped when the measured cooling water

temperature difference falls below a threshold value, i.e. as soon as a

solvent has been completely distilled off.

Drying

The cooling water temperature difference is not monitored if this option

is activated, e.g. use in processes for drying powdered media.

Heat rejection rate threshold

A limit value can be set for the heat rejection rate that is appropria-

te for the condenser used; see "useful information" section. The actual

heat rejection rate is calculated during every distillation process. If the

threshold is exceeded, the distillation will be stopped and an error mes-

sage displayed.

Maximum heat rejection rate

The maximum heat rejection rate achieved during the last distillation is

displayed. This value is for information purposes only.

Quantity meas. unit

Select between millilitre and gram as the unit of quantity.

Boiling point recognition

Boiling point recognition can be either activated or deactivated. Boiling

point recognition is only possible in "100%" mode for the distillation

method.

The boiling point recognition function automatically detects the boiling

point of a solvent.

Vacuum settings

Turn the Rotating/ Pressing knob to the right/left to select a menu

option.

Press the Rotating/ Pressing knob.

Turn the Rotating/ Pressing knob to change the value (the magnitude

of the change is dependent on the speed at which the knob is turned).

Press the Rotating/ Pressing knob again to complete the process.

SET key: Exit menu and save changes.

ESC key: Exit menu without saving changes.

Hysteresis

The default settings for the hysteresis (as shown) are suitable for use in

most situations. The (vacuum) hysteresis value describes the difference

between the closing and opening pressures for the vacuum valve.

Time scaling

The time axis of the vacuum-rotation-time graph is scaled using the value

specified here. If the value = 0, then the time axis is scaled automatically.

Vacuum scaling

The vacuum axis of the vacuum-rotation-time graph is scaled using the

value specified here. If the value = 0, then the vacuum axis is scaled

automatically.

Vacuum meas. unit

Select between the units of measurement for a vacuum: mBar, Torr, and

hPascal.

55

Drive settings

Turn the Rotating/ Pressing knob to the right/left to select a menu

option.

Press the Rotating/ Pressing knob.

Turn the Rotating/ Pressing knob to change the value (the magnitude

of the change is dependent on the speed at which the knob is turned).

Press the Rotating/ Pressing knob again to complete the process.

SET key: Exit menu and save changes.

ESC key: Exit menu without saving changes.

Right/left interval

Setting a particular value X for the right/left interval will cause the drive

to change the direction of rotation every X seconds.

Note: In interval mode the maximum speed is limited to 200 rpm.

Timer

The timer value determines the time after which a manual distillation will

be stopped.

Time scaling

The time axis of the vacuum-rotation-time graph is scaled using the value

specified here. If the value = 0, then the time axis is scaled automatically.

Rotation scaling

The rotation axis of the vacuum-rotation-time graph is scaled using the

value specified here. If the value = 0, then the rotation axis is scaled

automatically.

Bath settings

Turn the Rotating/ Pressing knob to the right/left to select a menu

option.

Press the Rotating/ Pressing knob.

Turn the Rotating/ Pressing knob to change the value (the magnitude

of the change is dependent on the speed at which the knob is turned).

Press the Rotating/ Pressing knob again to complete the process.

SET key: Exit menu and save changes.

ESC key: Exit menu without saving changes.

Medium bath

Select either water or oil as the medium for the heating bath.

Language

Turn the Rotating/ Pressing knob to the left/right to select the lan-

guage.

Confirm the selection by pressing SET.

56

Service

Turn the Rotating/ Pressing knob to the right/left to select a menu

option.

Press the Rotating/ Pressing knob.

Turn the Rotating/ Pressing knob to change the value (the magnitude

of the change is dependent on the speed at which the knob is turned).

Press the Rotating/ Pressing knob again to complete the process.

ESC key: Exit menu, all changes to switch settings are reset, the calibra-

tion remains unaffected.

Switching valves and pump

To check functionality for servicing purposes, use the Service menu to

activate/deactivate directly the valves included in delivery or optional and

the pump, e.g. RV 10.5001.

The RV 10.5001 valve switches the water circuit on and off. This row also

shows the current cooling water flow rate.

Calibrate

The “Calibrate” option is used for calibration of the temperature sensor.

The temperature difference displayed will be calibrated to zero. This ac-

tion cannot be reversed.

The temperature sensor must be calibrated whenever it is replaced or

changed, or if a new temperature sensor is installed.

Please contact the Service department.

The temperature sensor supplied with the system is calibrated ex-works.

Performing calibration

Activate the “Calibrate” menu option by turning the Rotating/ Pressing

knob.

Remove both sensors. To remove a sensor, push back the outer ring to

release the locking device on the push-in connector, while at the same

time pulling the temperature sensor out of the connector, see fig. 26.

To reconnect a temperature sensor, push it into the push-in connector

until the limit stop is reached; an initial resistance will be felt.

Fill water at room ambient temperature into a glass beaker (approx.

500 ml). Fully submerge both sensors into the water, see fig. 27.

Wait until the temperature display in the “Service” menu, menu opti-

on “Calibrate” has stabilised, e.g. 0.2K

Press the Rotating/ Pressing knob.

The temperature difference displayed will be calibrated to zero.

Calibration is only possible within the temperature range +0.5 K to -0.5

K. If the temperature is outside this range, then either a temperature

sensor is faulty or connected incorrectly. Please contact the Service de-

partment.

If the characteristics of the cooling water supply deviate significantly

from the specifications given in the “Technical specifications”, with the

result that the initial conditions for automatic distillation are not achie-

ved, then it may be necessary to recalibrate the temperature sensors.

This may, however, lead to a reduction in the accuracy with which the

distillate quantity is measured in “Auto-distillation” mode.

Operation hours

This value serves as informaton and cannot be changed.

Fig. 26

Fig. 27

57

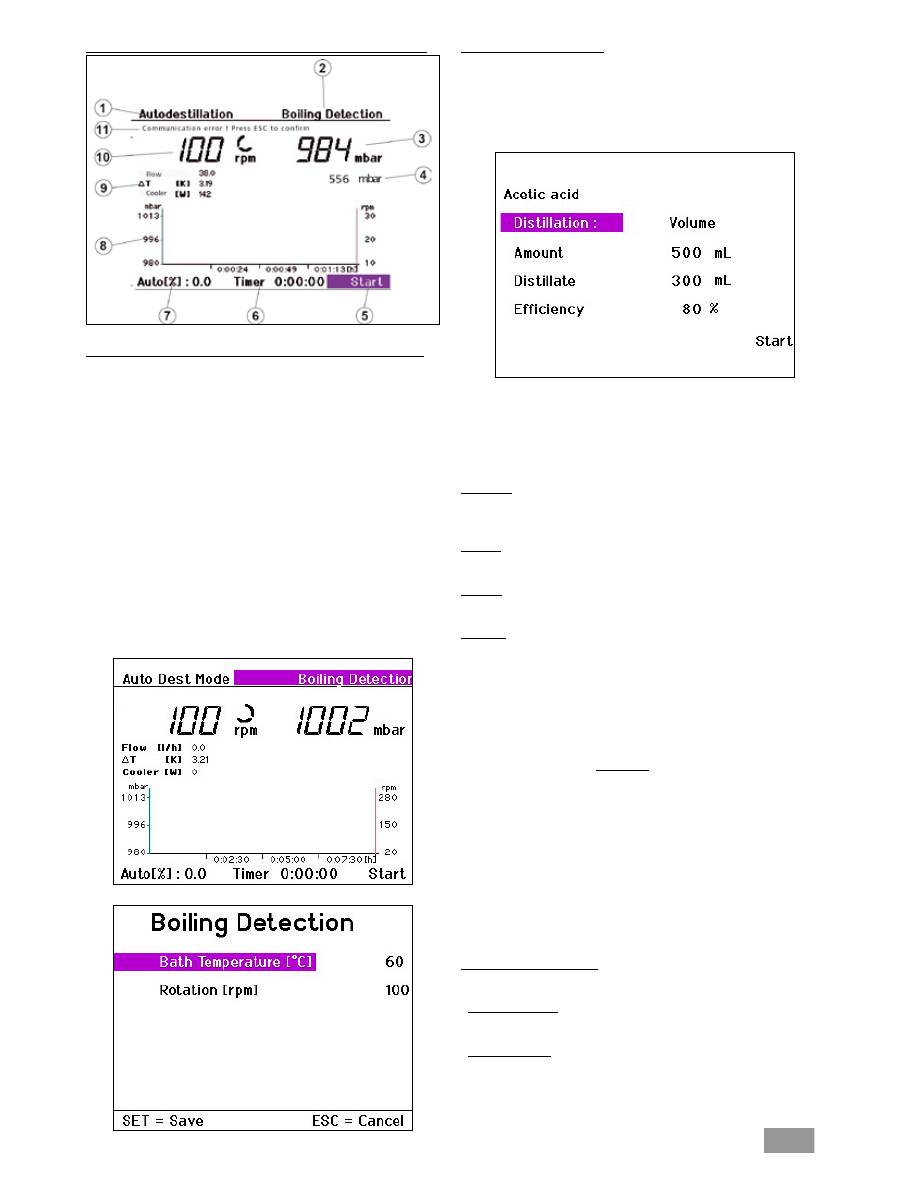

"Manual mode without boiling point recognition" menu

"Manual mode without boiling point recognition" display screen

1. Operating mode display

2. Vacuum display (actual value)

3. Vacuum display (target value)

4. Control field for „Start/ Stop“ distillation

5. Timer display

6. Control field for storing the distillation sequence

7. Vacuum-rotation-time graph

8. Display of flow rate, differential temperature, and condenser heat

rejection rate

9. Control field for rotary speed display (target value) and speed mea-

surement unit

10. Error message in case of fault, otherwise status indicator

Setting the rotary speed

Press the Rotating/ Pressing knob to change the target value.

Turn the Rotating/ Pressing knob to change the value (the magnitude

of the change is dependent on the speed at which the knob is turned).

Press the Rotating/ Pressing knob again to save and complete the

process.

Note: When you select the speed > 100 rpm, smooth start is automati-

cally activated.

Setting the vacuum

Press the Rotating/ Pressing knob to change the target value.

Turn the Rotating/ Pressing knob to change the value (the magnitude

of the change is dependent on the speed at which the knob is turned).

Press the Rotating/ Pressing knob again to save and complete the

process.

Start

Turn the Rotating/ Pressing knob to the right/left to select "Start".

Press the Rotating/ Pressing knob to start the distillation.

The display field will change to "Stop".

Note: If the timer has been configured, then the time will start to count

backwards. If a timer has not been configured then the time elapsed

since the start is shown.

Stop

Turn the Rotating/ Pressing knob to the right/left to select "Stop".

Press the Rotating/ Pressing knob to stop the distillation.

The display field will change to "Start".

Saving the distillation sequence as a procedure on completion of distillation

Turn the Rotating/ Pressing knob to the right/left to select "Save".

Press the Rotating/ Pressing knob to display the "Procedures" screen.

Turn the Rotating/ Pressing knob to the left/right to select one of the

ten procedures. The sequence will be shown graphically.

Press SET, to overwrite the selected procedure with the current proce-

dure (the procedure that has just been completed) and exit the menu.

Pressing ESC will prevent the selected procedure from being overwrit-

ten.

Note: Distillation sequences saved in this manner can be repeated at

a later dater in the user-defined mode by selecting the corresponding

procedure.

58

"Manual mode with boiling point recognition" menu

"Manual mode with boiling point recognition" display screen

1. Operating mode display

2. Vacuum display (actual value)

3. Vacuum display (target value)

4. Control field for „Start/ Stop“ distillation

5. Timer display

6. Control field for storing the distillation sequence

7. Vacuum-rotation-time graph

8. Display of flow rate, differential temperature, and condenser heat

rejection rate

9. Control field for rotary speed display (target value) and speed mea-

surement unit

10. Error message in case of fault, otherwise status indicator

Setting the rotary speed

Press the Rotating/ Pressing knob to change the target value.

Turn the Rotating/ Pressing knob to change the value (the magnitude

of the change is dependent on the speed at which the knob is turned).

Press the Rotating/ Pressing knob again to save and complete the

process.

Note: When you select the speed > 100 rpm, smooth start is automati-

cally activated.

Start

Turn the Rotating/ Pressing knob to the right/left to select "Start".

Press the Rotating/ Pressing knob to start the distillation.

The display field will change to "Stop".

Note: If the timer has been configured, then the time will start to count

backwards. If a timer has not been configured then the time elapsed

since the start is shown.

Stop

Turn the Rotating/ Pressing knob to the right/left to select "Stop".

Press the Rotating/ Pressing knob to stop the distillation.

The display field will change to "Start".

Saving the distillation sequence as a procedure on completion of distillation

Turn the Rotating/ Pressing knob to the right/left to select "Save".

Press the Rotating/ Pressing knob to display the "Procedures" screen.

Turn the Rotating/ Pressing knob to the left/right to select one of the

ten procedures. The sequence will be shown graphically.

Press SET, to overwrite the selected procedure with the current proce-

dure (the procedure that has just been completed) and exit the menu.

Pressing ESC will prevent the selected procedure from being overwrit-

ten.

Note: Distillation sequences saved in this manner can be repeated at

a later dater in the user-defined mode by selecting the corresponding

procedure.

59

"Auto-distillation mode without boiling point recognition" menu

"Auto-distillation mode without boiling point recognition" display screen

1. Operating mode display

2. Control field for solvent

3. Vacuum display (actual value)

4. Vacuum display (target value)

5. Control field for „Start/ Stop“ distillation

6. Timer display

7. Distillation progress indicator

(% of required quantity of distillate)

8. Vacuum-rotation-time graph

9. Display of flow rate, differential temperature, and condenser heat

rejection rate.

10. Rotary speed display (target value) and speed measurement unit

11. Error message in case of fault, otherwise status indicator

Changing the selected solvent

Turn the Rotating/ Pressing knob to the right/left to select the control

field "Solvent".

Press the Rotating/ Pressing knob to display a list of the various solvents

available.

Turn the Rotating/ Pressing knob to the right/left to select a "Solvent".

Press the SET key.

The solvent selected will be used for the subsequent distillation.

Note: The display shows the parameters for each of the solvents. The

parameters can only be changed for the user-definable solvents User-

Solvent1 ... UserSolvent5. Please refer to the next section for instructions

on how to do this.

User defined solvents

Select one of the options NewSolvent1 ... NewSolvent5 from the "Sol-

vents" screen.

Select one of these solvents and press the Rotating/ Pressing knob.

All the parameters displayed for the solvent can now be modified.

Turn the Rotating/ Pressing knob to the right/left to select the para-

meter to be changed.

Press the Rotating/ Pressing knob.

Turn the Rotating/ Pressing knob to the right/left to change the selec-

ted parameter.

Press the Rotating/ Pressing knob.

Press SET to save all values.

This action selects NewSolvent1 as the current solvent.

Note: It is not possible to return to the selection list.

60

Starting automatic distillation

Press the Rotating/ Pressing knob with the “Start” or “Continue” field

selected. If the “100% distillation” or “Drying” options are active, then

the distillation will start immediately, provided that the necessary condi-

tions are fulfilled.

When the “Volume” distillation method is used, a further screen with

additional distillation parameters will be displayed.

Turn the Rotating/ Pressing knob to the right/left to select a menu

option.

Press the Rotating/ Pressing knob.

Turn the Rotating/ Pressing knob to change the value (the magnitude

of the change is dependent on the speed at which the knob is turned)

Press the Rotating/ Pressing knob again to complete the process.

Distillation

This field indicates the distillation method selected in Settings/Distillation

and cannot be changed.

Amount

Enter the amount, which the flask contains.

Distillate

Enter the amount, which you want to distill off.

Efficiency

Balancing requires a precise thermal efficiency to be entered.

The efficiency is dependent on a combination of factors that affect the

distillation process, so it must initially be estimated. The first time a di-

stillation process is carried out should therefore be used for calibration.

Following completion of the distillation process, determine the quantity

of distillate produced and calculate the actual heat rejection rate accor-

ding to the following formula:

η

th

. m

(calc)

η

P

=

m

(gem)

η

P

Actual efficiency

η

th

Estimated efficiency

m

(gem)

Measured quantity of distillate

m

(calc)

Specified (calculated) distillate quantity

For subsequent distillations, the actual calculated efficiency should be

entered; this will ensure that subsequent automatic distillations under

the same distillation and ambient conditions are performed with suffici-

ent precision.

End of automatic distillation

Automatic distillation will stop when the following conditions are met:

- Volume controlled

The specified quantity of distillate has been reached.

- 100% Distillation

The measured cooling water temperature has fallen below a target va-

lue, indicating that the solvent is fully evaporated.

The distillation can also be stopped manually:

Press the Rotating/ Pressing knob with the “Stop” display field selected.

"Auto-distillation mode with boiling point recognition" menu

"Auto-distillation mode with boiling point recognition" display screen

1. Operating mode display

2. Control field for solvent

3. Vacuum display (actual value)

4. Vacuum display (target value)

5. Control field for „Start/ Stop“ distillation

6. Timer display

7. Distillation progress indicator

(% of required quantity of distillate)

8. Vacuum-rotation-time graph

9. Display of flow rate, differential temperature, and condenser heat

rejection rate

10. Rotary speed display (target value) and speed measurement unit

11. Error message in case of fault, otherwise status indicator

Note: volume distillation is not possible as the solvent must be known

in this mode.

This mode allows selection of the bath temperature and speed of rota-

tion via the "Boiling point recognition" control field instead of selection

of the solvent.