Partner PFT3540 B: instruction

Class: Gardening equipment

Type:

Manual for Partner PFT3540 B

Mod. POLO - POLO 2004 -

URSUS - MEPPY

INSTRUCTION MANUAL

LIBRETTO D’ISTRUZIONI

IMPORTANT INFORMATION: Please read these instructions

INFORMAZIONI IMPORTANTI: Leggere le istruzioni attenta-

carefully and make sure you understand them before using this

mente e capirle bene prima di usare l’utensile. Conservare

unit. Retain these instructions for future reference.

per ulteriore consultazione.

BETRIEBSANWEISUNG

HASZNÁLATI ÚTMUTATÓ

WICHTIGE INFORMATION: Lesen Sie diese Hinweise zur

Jótállást vállalni csak rendeltetésszerüen használatba vett

Handha-bung des Geräts aufmerksam durch. Verwenden

gépekre tudunk. Kérj ü hogy a gép használatba vétele elött

Sie es erst, wenn Sie sicher sind, daß Sie alle Anweisungen

gondosan olvassa el a kezelési utasításokat.

verstanden haben und gut aufbewahren.

EΓXEIPI∆IO XEIPIΣMOE

MANUEL D’INSTRUCTIONS

ΣHMANTIKEΣ ΠΛHPOΦOPIEΣ: ∆ιαβάστε προσεxτιxά αvτές

RENSEIGNEMENTS IMPORTANTS: Avant d’utiliser cet appareil,

τις οδηγίες xαι Φροvτίστε vα τις xαταvoήσετε αvτό το µηχάvηµα

veuillez lire atentivement les instructions et assurez-vous de les avoir

xαι Φuλάξτε το για vα το σuµβulλεύεστε στ µέλλοv.

comprises. Conservez les instructions pour référence ultérieure.

NÁVOD K POUŽÍVÁNÍ

HANDLEIDING

DŮLEŽITÁ INFORMACE! Než začnete stroj použivat přečtěte

BELANGRIJKE IMPORTANTS: Lees deze handleiding aan-

si prosím velmi pozorně tyto instrukce a ujistěte se, že jste jim

dachtig en zorg dat u ailes begrijpt alvorens de kettingzaag te

porozuměli. Uschovejte si tento návod pro použití i v budoucnu.

gebrulken en be-waar ze voor toekomstige raadpleging.

PRÍRUČKA

BRUKERHÅNDBOK

IMPORTANT INFORMATION: Please read these instructions

VIKTIG INFORMASJON: Les disse anvisningene nøye og

carefully and make sure you understand them before using this

forsikre deg om at du forstår dem før du bruker enheten og

unit. Retain these instructions for future reference.

oppbevar dem for sen-ere bruk.

INSTRUKCJA OBSŁUGI

OHJEKIRJA

Gwarancja traci ważność w przypadku używania urządzenia

TÄRKEÄÄ TIETOA: Lue nämä ohjeet huolellisesti ja varmista,

do celów innych niż wymienione w instrukcji obsługi. Prosimy o

että olet ymmärtänyt ne, ennen kuin alat käyttää tätä laitetta ja

uważne przeczytanie instrukcji oraz o stoowanie się do zaleceń

säilytä myöhempää tarvetta varten.

i wskazówek w niej zawartych.

BRUKSANVISNING

ИНCTPYKЦИИ

VIKTIG INFORMATION: Läs instruktionerna noggrant och för-

BAЖHЫE CBEДEHИЯ: Bнимaтeльнo пpoчитать инстрyкции

säkra dig om att du förstår dem innan du använder utrustningen

и хрoщo их пoнять, пepeд тeм как пoльзoвaтьcя блoкoм.

och spara dem för framtida behov.

Хpaнить инcтpyкции для дaльнейшиx кoнcyльтаций.

BRUGERHÅNDBOG

KASUTUSJUHEND

VIGTIGE OPLYSNINGER: Læs instruktionerne omhyggeligt,

TÂHTIS INFORMATSIOON: Lugege kasutusjuhend enne

før du bruger enheden og gemme til senere henvisning.

seadme kasutamist kindlasti põhjalikult läbi ning veenduge,

et olete kõigest täpselt aru saanud.

MANUAL DE INSTRUCCIONES

NAUDOJIMOSI INSTRUKCIJA

INFORMACIÓN IMPORTANTE: Lea atentamente las instruccio-

SVARBI INFORMACIJA: prieš pradedant dirbti įrenginiu,

nes y asegúrese de entenderlas antes de utilizar esta aparato.

prašome atidžiaiperskaityti šią instrukciją ir įsitikinti, kad viską

Conserve las instrucciones para la referencia en el futuro.

supratote. Išsaugokite ją tolimesniam naudojimui.

MANUAL DO OPERADOR

KNJIŽICA Z NAVODILI

INFORMAÇÕES IMPORTANTES: Queira ler cuidadosamente

POMEMBNA NAVODILA: Pozorno preberite navodila. Dobro jih

estas instruções e tenha certeza de entendë las antes de usar

morate razumeti, preden začnete uporabljati to orodje.

a serra e guarde para consulta futura.

Due to a constant product improvement programme,

La casa produttrice si riserva la possibilità di variare

GB

IT

the factory reserves the right to modify technical

caratteristiche e dati del presente manuale in

details mentioned in this manual without prior notice.

qualunque momento e senza preavviso.

This manual has been prepared for use with different

Questo manuale è stato redatto per essere utilizzato

models of Petrol Tiller having different shapes and

con diversi modelli di motozzappe con forme ed

equipment.

equipaggiamenti differenti.

Im Sinne des Fortschritts behält sich der Hersteller das

A gyártó cég fenntartja a jogot arra, hogy a használati

DE

HU

Recht vor, technische Änderungen ohne vorherigen

utasitásban megadott adatokon és technikai

Hinweis durchzuführen.

tulajdonságokon bármikor és elözetes bejelentés

nélkül változtasson.

Diese Bedienungsanleitung wurde für verschiedene

Ez a kézikönyv, azért lett létrehozva, hogy segítségre

Benzin Bodenhacken geschrieben.

legyen a különböző formájú és felszerelésű elektro-

La Maison se réserve la possibilité de changer des

mos kapák használatában.

FR

caractéristiques et des données de ce manuel à

Λόγω προγράμματος συνεχο'θς βελτíωσης προιόντων,

n'importe quel moment et sans préavis.

GR

το εργοστάσιο επιφυλάσσεται του δικαιώματος να

Ce Manuel a été rédigé pour être utilisé avec

τροποποιεί τις τεχνικές λεπτομέρειες που αναφέρονται

différents modèles de houes à moteur avec formes

στο εγχειρίδιο αυτό χωρίς προηγούμενη ειδοποίηση.

et équipements différents

Door konstante produkt ontwikkeling behoud de

NL

fabrikant zich het recht voor om rechnische specicaties

zoals vermeld in deze handleiding te veranderen

zonder biervan vooraf bericht te geven.

Vzhledem k pokračujícím inovacím si vyrobce

CZ

výhrazuije právo mínit technické hodnoty uvedené v

Deze handleiding is samengesteld voor het gebruik

této přiručce bez predčhozího upožornení.

van verschillende modellen van Petrol Tiller van

verschillende afmetingen en accessoires.

Obsah této příručky lze použít pro různé typy motoro-

vých kultivátorů, lišících se tvarem i vybavením

Produsenten forbeholder seg all rett og mulighet til

NO

å forandre tekniske detaljer i denne manualen uten

Na základe programu neustáleho zlepšovania produktov

SK

forhåndsvarsel.

si výrobný závod vyhradzuje bez predchádzajúceho

upozornenia právo na zmenu technických parametrov

Denne håndboken er beregnet til bruk med ulike

uvedených v tejto príručke.

modeller av Petrol Tiller, som har forskjellige fasonger

og utstyr.

Táto príručka slúži pre rôzne modely benzínových

kul tivá toro v roz ličn ých tv arov a s rô zn ym

Jatkuvan tuotteen parannusohjelman tähden valmistaja

FI

príslušenstvom..

pidättää oikeuden vaihtaa ilman ennakkovaroitusta

tässä ohjekirjasessa mainittuja teknisiä yksitsyikohtia.

W związku z programem ciąglego ulepszania swoich

PL

wyrobów producent zastrzega sobie prawo do

Tätä opasta on muutettu, jotta sitä voidaan käyttää

wprowadzania zmian w szczególach technicznych

eri moottorijyrsinmallien kanssa, joiden muodot ja

wymienionych w tej instrukcji bez uprzedniego

varusteet eroavat toisistaan

zawiadomienia. Instrukcja jest częścią wyposaże.

Tilverkaren reserverar sig rätten att ändra fakta och

SE

Książeczka ta została opracowana do wykorzystania

uppgifter ur handboken utan förvarning.

dla różnych modeli motyk mechanicznych o różnych

Denna bruksanvisning är skriven för olika modeller

formach i wyposażeniu

av elektriska gräsklippare med olika utseende och

utrustning.

Компания производитель сохраняет за собой

RU

право изменять характеристики и данные в

Producenten forbeholder sig ret til ændringer, hvad

DK

настоящем руковдстве, в любой момент и без

angår karakteristika og data i nærværende instruktion,

предварительного извещения.

når som helst og uden varsel.

Данное руководство было подготовлено для

Denna bruksanvisning är skriven för olika modeller

использования с различными моделями машин

av bensindrivna jordfräsar med olika utseende och

бензиновая почвенная фреза различных форм и

utrustning

оборудования

La rma productora se reserva la posibilidad de

ES

Tootja jätab endale õiguse muuta käesolevas

cambiar las características y datos del presente

EE

kasutusjuhendis kirjeldatud omadusi ja andmeid

manual en cualquier momento y sin previo aviso.

suvalisel hetkel ja sellest eelnevalt ette teatamata.

El presente manual se ha redactado para utilizarse

See kasutusjuhend on koostatud kasutamiseks

con distintos modelos de azadas eléctricas con

bensiinimootoriga pinnasefreesi eri mudelitega, millel

formas y equipos diferentes

võib olla erinev kuju ja varustus.

A casa productora se reserva a possibilidade de

Kadangi gaminis nuolat derinamas, įmonė palieka

PT

LT

variar características e dados do presente manual em

sau teise keisti techninius duomenys, apie kuriuos yra

qualquer momento e sen aviso prévio.

nurodyta šioje instrukcijoje, be išankstinio pranešimo.

Este manual foi redigido para ser utilizado em diver-

Instrukcija buvo paruošta įvairių benzininė dirvinė fre-

sos modelos de Motoenxada, com forma e equipa-

za naudojimui, kurios tūri įvairias formas ir įrangą.

mento diferentes

Proizvajalec si pridržuje pravico do spremembe

SL

karakteristik in podatkov v tem priročniku v katerem

koli trenutku brez predhodnega obvestila.

Ta priročnik je namenjen uporabi različnih modelov

motornega okopalnika različnih oblik in z različno

opremo.

2

We wish to thank you for choosing our petrol tiller. We are condent that the high quality of our machine will meet with

your satisfaction and appreciation and that your vacuum cleaner will give you long-lasting service.Before starting to use

your machine, make sure to read with care this manual, which has been purposely drawn up to provide you with all the

necessary information for proper use, in compliance with basic safety requirements.

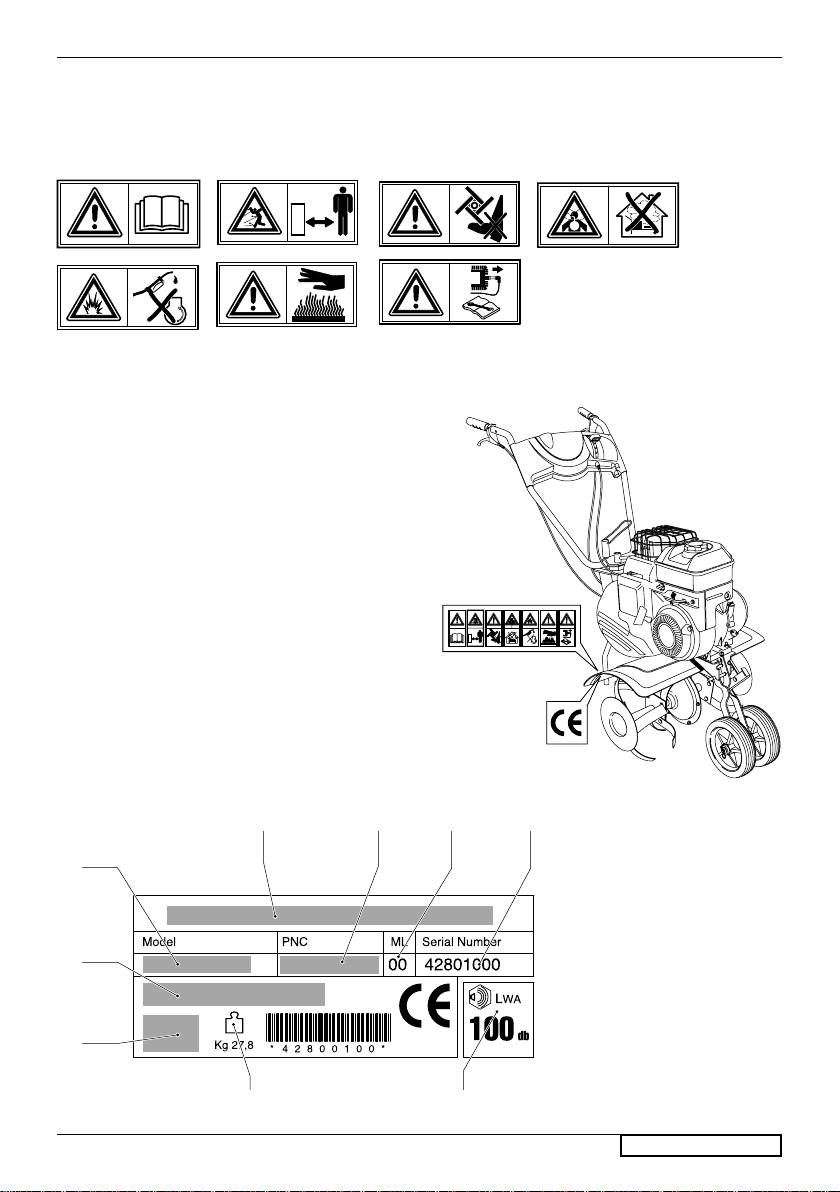

1 2 3 4

5 6 7

Caution! Read the instruction manual before

1

use

2

Keep other people well away from the danger

area!

3

Caution!Cutting tool and moving parts.

4

Risk of breathing in toxic gases ! Do not use the

appliance in closed or poorly ventilated environ-

ments.

5

Risk of explosion ! Do not top up with fuel with

engine running.

6

Caution! Hot surface

Caution! Switch off the engine and disconnect

7

the spark plug before undertaking any mainte-

nance work

1 Manufacturer

2 Model

3 Product number

4 Maintenance lever

5 Serial number

6 Type

7 Engine info

8 Weight

9 Sound power level

ENGLISH -

1

1

3

4

5

2

6

7

8

9

SAFETY RULES

Training

a)Persons under 16 years of age and persons who are

replace the fuel tank cap and tighten it down rmly.

not acquainted with the user instructions must not

f)The machines with internal combustion engines

use the petrol tiller.Do not allow children or anyone

must never be operated in closed environments

who has not understood these instructions to use the

on account of the danger of carbon monoxide

petrol tiller. A minimum age for using the machine

poisoning.

can be xed by local regulations.

g)The safety distance, which is set by the length

b)The operator is responsible for the safety of other

of the handle, must always be kept. Furthermore,

people in the working area. Keep children and do-

when the engine is working, never run; you must

mestic animals at a safe distance when the petrol

always walk.

tiller machine is in use.

h)articular precautions must be taken when using

c)This petrol tiller may be used exclusively for breaking

the rotary hoe machine on slopes or downhill

and loosening natural soil. Its use is not allowed for

stretches:

other purposes (e.g. for cutting branches).

use appropriate antislip footwear

d)Work only when there is sufcient light.

watch where you put your feet

e)Before you start using the petrol tiller machine,

always move sideways with respect to the slope;

make sure to remove any objects or obstacles that

never move uphill or downhill

might be present. While you are using the petrol

take great care when changing direction

tiller machine, keep your eyes open for the possible

do not work on excessively steep slopes.

presence of such objects that may have been left

i)Never use the petrol tiller machine with faulty guards

on the ground.

or protections or without safety devices installed and

Setting up and operating the engine

in proper order.

a)When using the petrol tiller machine, wear strong

j)For reasons of safety, the engine must never exceed

footwear (boots or heavy shoes) and long trou-

the number of revs (r.p.m.) indicated on the data

sers.

plate.

b)Before you start working, make sure that the cutting

k)Take care when starting the engine and make sure

tools are securely fastened. If they were to present

to follow the user instructions. When the engine is

any major damage, they must be replaced.

turning, it is absolutely necessary to prevent anybody

c)During engine startup, under no circumstances lift

from approaching the moving parts.

up the machine.

d)Turn off the engine and disconnect the cap of the

Maintenance and storage

spark plug whenever:

a)Make sure that all nuts, bolts and screws are kept

removing the protection devices

well tightened down so as to work in conditions of

transporting, lifting or displacing the machine from

perfect safety.

the working area

b)Never leave the machine with fuel in the tank

carrying out maintenance or cleaning

where the fuel vapours could reach naked ames

carrying out any operation on the cutting tools

or sparks.

c)Give the engine enough time to cool off before

leaving the petrol tiller machine unattended.

CAUTION! The tools keep turning for a few secon-

putting the equipment in any narrowly enclosed

ds even after the engine has been turned off.

environment.

e)CAUTION! The fuel is highly inammable:

d)Keep the engine, silencer, battery compartment

keep the fuel only in the fuel cans provided for that

and petrol tank free from grass, leaves and excess

purpose

lubricant in order to reduce the danger of re.

pour the fuel into the tank only in the open air and

e)For safety reasons, make sure to replace worn-out

make sure not to smoke

or damaged parts in due time.

fill up the fuel tank before starting the engine.

f)Should you drain off the fuel tank in order to store

Under no circumstances open the fuel tank cap or

the rotary hoe machine away for the winter, make

add petrol when the engine is running or when it

sure to carry out this job in the open air.

is still hot

g)Install the cutting tools following the corresponding

if the petrol has overowed, do not under any circu-

instructions and use exclusively tools bearing the

mstances start up the engine. Take the machine out

Manufacturer's or Supplier's name or trademark and

of the area where the fuel has been spilt and avoid

the reference number.

any source of possible ignition until the petrol fumes

h)To protect your hands during disassembly or as-

have dissipated

sembly of

the cutting tools, wear suitable protective

gloves.

ENGLISH -

2

DESCRIPTION (starts at page II)

1 Handles

12 Clutch lever

2 Accelerator

13 Reverse lever

3 Dash-board

14 Side disk

4 Rod

15 Oil ller cap

5 Transport wheels

16 Oil drain plug

6 Hoeing blades

17 START/STOP switch

7 Protection guard

18 Filter cap for gearbox

8 Fuel tank

19 Drain plug for gearbox

9 Spark plug

20 Motor

10 Engine startgrip

21 Handle plate

11 Reduction gear

22 Safety handle

ASSEMBLY

Skid (4): indroduced the skid into the seat an the frame

(23) and x with cotter pin (26).

MOD. 1

(Fig.BI)

Wheel (5):

Mount the wheel rod (27) an the frame (23)

and then x with screw, washer and nut (28). Introduce

MOD. 2 (Fig.BII)

cotter pin (29).

Accelerator lever (Governor) (2): (this refers only to the

MOD. 4 (Fig.BIII)

version with 4-stroke engine). Fix the governor to the

ASSEMBLY OF: HANDLES - SKID - WHEEL - ACCE-

handles (1) by means of screw and nut (30).

LERATOR LEVER - OFF-SWITCH.

Switch (17): (this refers anly to the version with 2-stroke

Handles (1): mount handle-plate (21) in the frame (23)

engine). Introduce the terminals of grounding cables (31)

and x it with four screws, washers and nuts (24). Now

into the xing spots of the switch.

introduce the two handles (1) into the handle-plate and

x them with screws, washers and wing screws(25).

MOD. 4 (Fig.BIV)

SAFETY DURING USE

Before you start working, make sure to remove

The operator is responsible for the safety of other people

any objects or obstacles that may have been left

in the working area.

on the lawn.

ENGINE ADJUSTMENTS

Refer to the engine manufacturer's maintenance

CAUTION:- 0.6l Oil must be added to the engine before

manual.

use.

ADJUSTMENT OF HANDLES (for the models where it is included only)

MOD. 1 (Fig.EI)

MOD. 2 (Fig.EII)

MOD. 4 (Fig.EIII)

ENGLISH -

3

OPERATION

MOD.1 (Fig.FI-FII-FIII-FIV-FV)

MOD.2

(Fig.FVI-FVII-FVIII-FIX-FX)

Once the machine has been set up properly, start the

Once the machine has been set up properly, start the

engine as follows:

engine as follows:

Before starting work, it is necessary to carry out the

Before starting work, it is necessary to carry out the

following:

following:

- set the trasport wheels (5) upwards.

- set the trasport wheels (5) upwards.

a)Engines with choke system:

a)Engines with choke system:

if

the model is equipped with an accelerator, when the

if the model is equipped with an accelerator, when

engine is cold, position the accelerator lever (2) on

the engine is cold, position the accelerator lever (2)

START

on START

Engines with primer system:

Engines with primer system:

Press the fuel-enrichment pump located on the car-

Press the fuel-enrichment pump located on the car-

burettor 3 or 4 times.if the model is equipped with an

burettor 3 or 4 times.if the model is equipped with an

accelerator, position the accelerator lever (2) on MAX.

accelerator, position the accelerator lever (2) on MAX.

b) Grip the engine start grip (10) and pull the starter

b) Grip the engine start grip (10) and pull the starter

rope gently until you feel the resistance caused by

rope gently until you feel the resistance caused by

compression. Release the handle; then give the starter

compression. Release the handle; then give the starter

rope a sharp tug.

rope a sharp tug.

For further information and explanations, read careful-

For further information and explanations, read careful-

ly the user instruction manual of the engine.

ly the user instruction manual of the engine

Initially position the hook (15) of the forward drive cable

WARNING! Never keep the two handles (12-13)

and the hook (16) of the reverse clutch cable in the holes

activated at the same time. It may cause damage

(II°) of the respective handles (1

2-13).

to the belts and pulleys

Should the handle action not follow the cutter clutch,

WHEN THE TILLER IS ON: in order to make the tiller

position the hook into hole (I°) of the handle, while on the

blades (6) run, handle (12) must be depressed. When

contrary insert it into hole (III°) should the cutters remain

working with the tiller, keep the handle depressed.

engaged even on release of the handle itself.

If the handle is released, the tiller blades will come to

WARNING! Never keep the two handles (12-13)

a stop.

a

ctivated at the same time. It may cause damage

Depress the skid in order to work in depth and decrease

to the belts and pulleys.

the pressure to move forwards.

WHEN THE TILLER IS ON: in order to make the tiller bla-

REVERSE-GEAR: for engaging the reverse-gear, only

des (6) run, handle (12) must be depressed. When working

handle (13) must be actuated.

with the tiller, keep the handle depressed. If the handle is

How to stop the engine: for this purpose, shift the accele-

released, the tiller blades will come to a stop.

rated lever into STOP position.

Depress the skid in order to work in depth and decrease

the pressure to move forwards.

The four cutter stars (6) can be pulled off, and the combina-

tion of cutters allows working widths from

25 to 55 cms.

REVERSE-GEAR: for engaging the reverse-gear, only

handle (13) must be actuated.

For assembly, introduce the blade star (6) to the rotary

shaft (N) and make the two holes (P) match: then introduce

How to stop the engine: for this purpose, shift the accele-

pin (R) by fastening it with the respective spring. Make sure

rated lever into STOP position.

that the hoeing blades are assembled in the right direction,

The four cutter stars (6) can be pulled off, and the combina-

i.e. the cutting angle showing forward.

tion of cutters allows working widths from

25 to 55 cms.

For assembly, introduce the blade star (6) to the rotary

shaft (N) and make the two holes (P) match: then introduce

pin (R) by fastening it with the respective spring. Make sure

that the hoeing blades are assembled in the right direction,

i.e. the cutting angle showing forward.

ENGLISH -

4

MOD.3 (Fig.FXI-FXII)

MOD.4 (Fig.FXIII-FXIV)

Once the machine has been set up properly, start the

Engine as follows:

engine as follows:

- Make sure that the clutch is disengaged (Handle (12)

1) 2-stroke engine version, position the switch (17) on

must be down-wards).

START to enable engine startup.

-

Lower lever of the safety handle (22) and insert the

1.a) Grip the starting handle (10) and pull the engine

reatining spring (38) into the appropriate notch.

start grip gently until you feel the resistance caused by

a)Engines with CHOKE SYSTEM:

compression. Release the handle; then give the starter

if

the model is equipped with an accelerator, when the

rope a sharp tug.

engine is cold, position the accelerator lever (2) on

2

) 4-stroke engine version:

START

2.a)Engines with choke system:

Engines with PRIMER SYSTEM:

P

ress the fuel-enrichment pump located on the car-

if the model is equipped with an accelerator, when

burettor 3 or 4 times.If the model is equipped with an

the engine is cold, position the accelerator lever (2)

accelerator, position the accelerator lever (2) on MAX.

on START

b) Start engine.

2.b)Engines with primer system:

Grip the starting handle (4) and pull the starter rope

Press the fuel-enrichment pump located on the carbu-

gently until you feel the resistance caused by compres-

rettor 3 or 4 times, if the model is equipped with an

sion. Release the handle; then give the starter rope a

accelerator, position the accelerator lever (2) on MAX.

sharp tug.

2.c) Grip the starting handle (10) and pull the starter

For further information and explanations, read careful-

rope gently until you feel the resistance caused by

ly the user instruction manual of the engine.

compression. Release the handle; then give the starter

rope a sharp tug.

Before starting work, it is necessary to carry out the

following:

For further information and explanation, read carefully

the Engine Manufacturers instruction manual.

- adjust the skid (4) according to the soil and to hoeing

depth to be obtained. For this job, introduce pin (39) in

Before starting work, it is necessary to carry out the

one of the holes on the skid and x it with the cotter.

following:

When engine is running. For making the hoeing blades

-adjust the skid (4) according to the soil and the depth of

turn proceed as follows:

hoe which is required, to do this insert the cotter pin (32)

in one of the holes on the skid and x it with clip.

- engage the clutch; for this operation pull the clutch lever

(1

2) upward until engaging is completed. The lever is

- set the trasport wheels (5) upwards. For this purpose

hold in this position by stop lever (40).

move the wheel rod (33) in the upper hole and x it

with cotter pin (34).

- Seize the safety lever (22) together with the handles.

By doing this, the retaining spring is released. Now, if

WHEN THE ENGINE IS ON: in order to make the tiller

the handle bars are released the engine woulf auto-

blades (6) run, handle (12) must be depressed. When

matically stop.

working with the tiller, keep the handle depressed. If

the handle is released, the hoeing blades will come

How to stop the engine: for this purpose, shift the acce-

to a “stop”

lerated lever into STOP position.

Depress the skid in order to work in depth and decrease

Disengagement of the clutch lever: pull retaining lever

the pressure to move forwards.

(40) in order to remove it from the hold position (For fa-

cilitating release, pull the lever slightly backwards). Now,

HOW TO STOP THE ENGINE:

let the handle go in oder to effect disengagement.

- 2-stroke engine version, set the interrup button to

STOP.

- 4 stroke engine version, set accelerator lever to STOP.

HOW TO MOUNT THE HOEING BLADES (6): mount

the hoeing blades an the rotary shaft (35) and make

two holes (36) coincide, then t pin (37) and x with the

respective spring.

ENGLISH -

5

MAINTENANCE

Caution! Switch off the motor and disconnect the spark

plug before undertaking any maintenance work.

Check regulary all screws and nuts for tightness

Engine: consult the instruction Manual of the engine-maker.

Wheels: axles must kept clean and sufciently greased

MOD.1 (Fig.GI-GII)

MOD.3 (Fig.GV-GVI)

Clutch lever (12): When the clutch wire is too slack and

Reduction gearbox (11): this unit contains approx. 150

does not permit a correct engagement, an adjustment

ml oil of the SAE 20/40 grade. Check the oil level through

of the clutch wire must be carried out by introducing the

the ller cap (18). After 60 operation hours change the

tie-bolt (41) in one of the next holes (X) of lever (12).

oil. for this purpose use the respective drain plug (18)

and the ller cap (19)

Drive blet (Z): For replacement of the belt, the following

steps must be carried out: take off the casing (T) by un-

Any detriment due to lack of checking the oil-lever or

screwing screw (S); replace the belt; then re-assemble

incorrect oil-change are not covered by guarantee.

the whole.

Clutch lever (12): When the clutch wire is too slack and

REVERSE-GEAR

does not permit a correct engagement, introduce spring

(47) into one of the subsequent holes on plate (48).

Restoring of belt tension (Q): When the clutch wire is

too slack and does not permit a correct engagement,

an adjustment of the clutch wire must be carried out

MOD.4 (Fig.GVII-GVIII)

by introducing the tie-bolt (42) in one of the next holes

Ball bearing lubricate periodically the entrance shaft

(Y) of lever (13).

to the reduction gear. For this reason, pour SAE 30

Drive-belt (Q): For replacing the belt, take off housing (T)

oil into oiler (A) which is located below the connection

by loosenisng screws (S). Then replacing the belt, take

ange.

off housing (T) by loosening screwa (S). Then replace

Reduction gearbox (11): this unit contains approx.

the belt and re-assemble the whole.

0.500 Kg oil of the SAE 120/140 grade. Check the oil

l

evel through the plug (18). After 20 operation hours

MOD.2 (Fig.GIII-GIV)

change the oil. for this purpose use the respective drain

Clutch lever (12): When the control cable works loose,

plug (18) and the ller cap (19)

no longer allowing the relevant coupling, the clutch cable

Any detriment due to lack of checking the oil-lever or

must be adjusted:

incorrect oil-change are not covered by guarantee.

- Unlock lock nut (43) and unscrew screw (44) for two

complete revolutions.

Clutch lever (12): When the wire slackens, thus not

- Fix position of screw (44) by tightening lock nut (43).

allowing correct engaging of the clutch, adjustment must

B

y acting on lever (12) make sure that cutters have

be effected. For this, turn screw (48) whitch is located

engaged. If not, repeat the operations above.

on the lever and on the steeldech.

Drive blet (Z): For replacement of the belt, the following

Drive blet (Q): These are subject to wear; therefore

steps must be carried out: take off the casing (T) by

the original tensioning should be restored or the belt de

unscrewing screw (S); replace the belt; then re-assem-

changed. For replacing te belts, proceed as follows:

ble the whole.

- release spring (49), loosen screw (50). (Is this way,

VERSION WITH REVERSE-GEAR

the bowden wire of the clutch does not hold the spring

Restoring of belt tension (Q): When the control cable

under tension).

works loose, no longer allowing the relevant coupling,

- release the two springs (51) and remove them from their

the clutch cable must be adjusted:

fastening seat.

-

Unlock lock nut (45) and unscrew screw (46) for two

-

take off the housing (52) by unscrewing the four screws

complete revolutions.

(53).

- Fix position of screw (46) by tightening lock nut (45).

By acting on lever (13) make sure that cutters have

- Loosen the two screws (54) and push the belt giudes

engaged. If not, repeat the operations above.

away (55) in order to permit changing of the belt.

Drive-belt (Q): For replacing the belt, take off housing (T)

After replacement of the belts, remount all part.

by loosenisng screws (S). Then replacing the belt, take

Be careful, during the remounting operation, to place the

off housing (T) by loosening screwa (S). Then replace

nylon guides (56) with the recess facing the operator. Now,

the belt and re-assemble the whole.

adjust tensioning of the cloutch wire.

ENGLISH -

6

GUARANTEE AND GUARANTEE POLICY

If any part is found to be defective due to faulty manufacture

Failures not covered by guarantee

within the guarantee period, Husqvarna Outdoor Products,

- Replacing worn or damaged blades

through its Authorised Service Repairers will effect the

- Failures as a result of not reporting an initial fault.

repair or replacement to the customer free of charge

- Failures as a result of sudden impact.

providing:

- Failures as a result of not using the product in accordance

a) The fault is reported directly to the Authorised Re-

with the instructions and recommendations contained in

pairer.

this Operator’s Manual.

b) Proof of purchase is provided.

- Machines used for hire are not covered by this gua-

c) The fault is not caused by misuse, neglect or faulty

rantee.

adjustment by the user.

- The following items listed are considered as wearing parts

d) The failure has not occurred through fair wear and

and their life is dependent on regular maintenance and

tear.

are, therefore not normally subject to a valid warranty

e) The machine has not been serviced or repaired, taken

claim: Blades, Electric Mains cable, Belt

apart or tampered with by any person not authorised by

- C

AUTION!

Husqvarna Outdoor Products.

Husqvarna Outdoor Products does not accept liability

f) The machine has not been used for hire.

under the warranty for defects caused in whole or part,

g) The machine is owned by the original purchaser.

directly or indirectly by the tting of replacement parts

h) The machine has not been used commercially.

or additional parts that are not either manufactured or

This guarantee is additional to, and in no way diminishes

approved by Husqvarna Outdoor Products, or by the

the customers statutory rights.

machine having been modied in any way..

Failures due to the following are not covered, therefore

it is important that you read the instructions contained in

this Operator’s Manual and understand how to operate

and maintain your machine:

EC DECLARATION OF CONFORMITY

I, the undersigned Bengt Ahlund, of Husqvarna Outdoor Products Italia Spa, Via Como 72, 23868 Valmadrera (LC).

Certify that the Petrol Wheeled Rotary:

Category .................................................................Petrol Wheeled Rotary

Make .......................................................................Husqvarna Outdoor Products

Conforms to the specications of Directive 2000/14/EEC

Type ........................................................................A

Version....................................................................B

Width of cut.............................................................C

Guaranteed sound power level...............................D

Measured sound power level..................................E

Sound pressure livel at the ear ...............................F

Vibration of the handle ............................................G

Diameter of cuttersr ................................................H

Cutter rpm...............................................................I

(See the last page for references)

Working equipment .................................................4/6 star cutter with 4 cutting tools each

Type of Cutting Device ............................................Rotary Blade

Identication of Series ............................................See Product Rating Label

Conformity Assesment Procedure ..........................ANNEX VI (<3kW), ANNEX V (>3kW)

Notied Body. .........................................................Nr. 0470 - NEMKO AS

Gaustadalleen 30 - PO Box 73 Blindern

0314 OSLO - Norway

Other Directives ......................................................98/37/EC, 2002/88/EC, 2004/108/EC

& applicable standards normative ..........................EN709,EN ISO14982,EN1033,EN ISO 3744,EN ISO11201

Technical Manager

Husqvarna Outdoor Products Italia spa

Via Como 72 - 23868 Valmadrera (LC)

ENGLISH -

7