Alexika HBC 5 basic – страница 2

Инструкция к Alexika HBC 5 basic

21

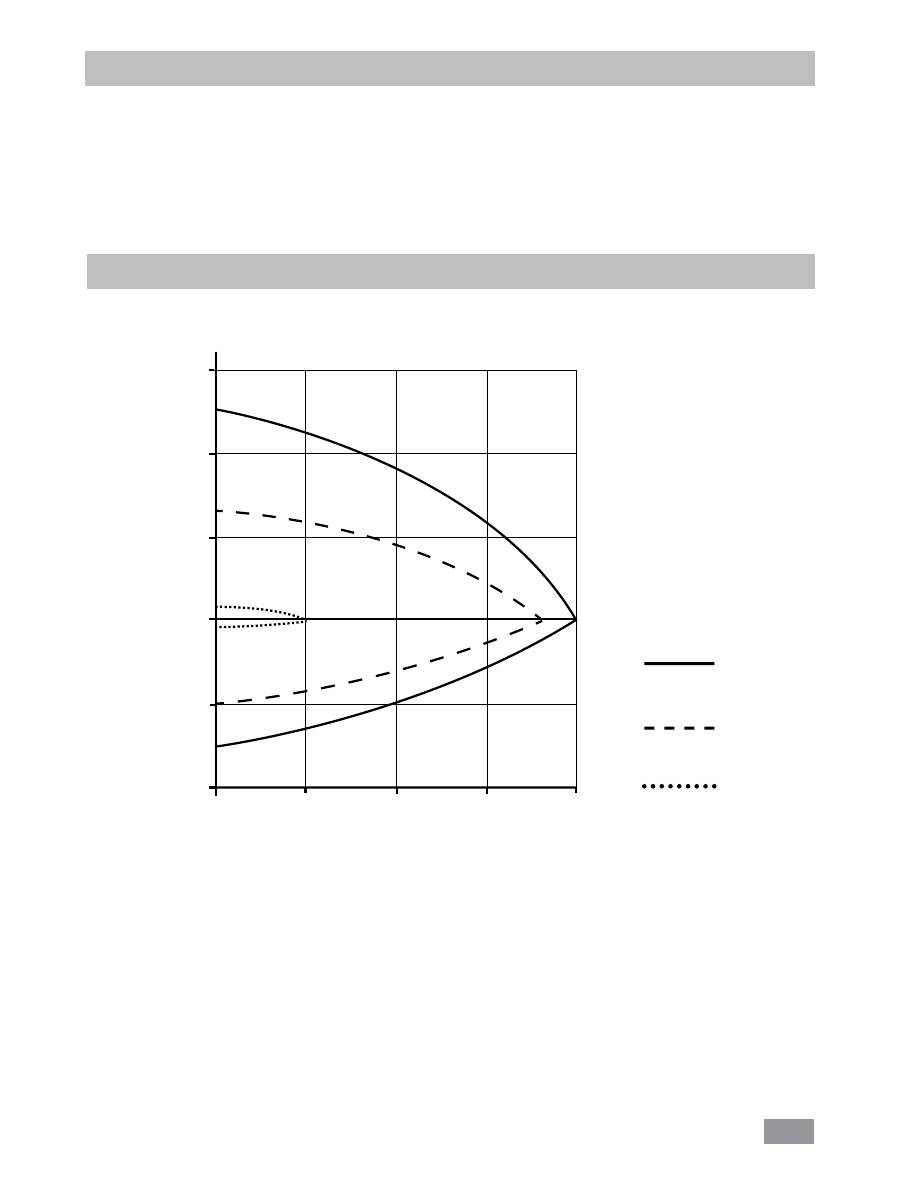

Pumpenkennlinie

Gewährleistung

Entsprechend den

IKA

®

-Verkaufs- und Lieferbedingungen

beträgt die Gewährleistungzeit 24 Monate. Im Gewährleis-

tungsfall wenden Sie sich bitte an Ihren Fachhändler. Sie

können aber auch das Gerät unter Beifügung der Liefer-

rechnung und Nennung der Reklamationsgründe direkt an

unser Werk senden. Frachtkosten gehen zu Ihren Lasten.

Die Gewährleistung erstreckt sich nicht auf Verschleißteile

und gilt nicht für Fehler, die auf unsachgemäße Handha-

bung und unzureichende Pflege und Wartung, entgegen

den Anweisungen in dieser Betriebsanleitung, zurückzufüh-

ren sind.

Pumpenkennlinie gemessen mit Wasser

0,6 0,4 0,2 0,0 -0,2 -0,4 0 5 10 15 20 Q [l/min] P [bar]

4000 rpm

3000 rpm

1000 rpm

Fig. 18

22

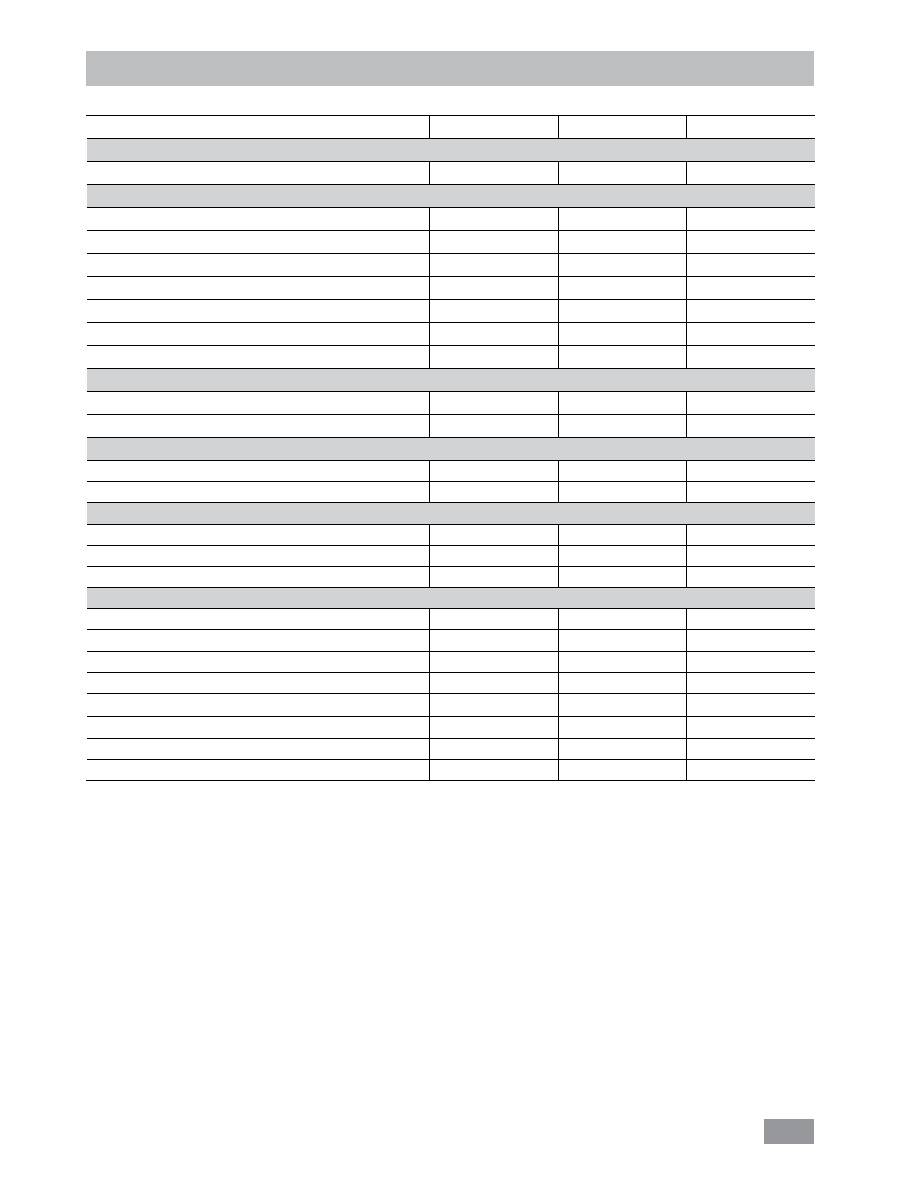

Contents

EN

Source language: German

Page

EC Declaration of Conformity ..................................................................................................................23

Explication of warning symbols ..............................................................................................................23

Safety instructions ..................................................................................................................................24

General information ....................................................................................................................................... 24

Fluids ............................................................................................................................................................. 25

Correct use ..............................................................................................................................................25

Use ................................................................................................................................................................ 25

Range of use (indoor use only) ....................................................................................................................... 25

Unpacking ...............................................................................................................................................26

Unpacking ..................................................................................................................................................... 26

Delivery scope ................................................................................................................................................ 26

Preparations ............................................................................................................................................26

Setting up ...................................................................................................................................................... 26

Connecting the tubings .................................................................................................................................. 26

Filling and draining ......................................................................................................................................... 27

Fluids ............................................................................................................................................................. 27

Cooling coil .................................................................................................................................................... 28

Operator panel and display .....................................................................................................................28

Commissioning ........................................................................................................................................29

Setting the safety temperature ...............................................................................................................29

Menu settings .........................................................................................................................................30

Menu structure .............................................................................................................................................. 30

Basic guide to setting the menu options ......................................................................................................... 30

Operating mode (MODE)................................................................................................................................ 30

Maximum temperature (HI T) ......................................................................................................................... 30

Minimum temperature (LO T) ......................................................................................................................... 30

Maximum speed (HI R) ................................................................................................................................... 30

Minimum speed (LO R) ................................................................................................................................... 31

Fluid type (FLUI) ............................................................................................................................................. 31

The type of temperature PID control arithmetic (AUTO) .................................................................................. 31

External and internal temperature control (ET) ................................................................................................ 32

Alarm and key tone (BEEP) ............................................................................................................................. 32

Calibration (CALI) ........................................................................................................................................... 32

Interface and output ...............................................................................................................................33

Maintenance and cleaning ......................................................................................................................35

Error codes ..............................................................................................................................................36

Accessories ..............................................................................................................................................37

Technical data .........................................................................................................................................38

Warranty .................................................................................................................................................39

Pump performance curve ........................................................................................................................39

23

EC Declaration of Conformity

Explication of warning symbols

DANGER

General hazard

This symbol identifies information

that is of vital importance for protecting your health

and safety

. Disregarding this information may lead to health impairment and injuries.

This symbol identifies information

that is of importance for the technically correct func-

tioning of the system

. Disregarding this information may result in damage to the device or

to system components.

This symbol indicates information

which is important for proper use and ensuring that

the operations of the device are performed efficiently and for using the device

.

Fail-

ure to observe this information may result in inaccurate results.

Danger

- Reference to exposure to a hot surface!

Hot surface!

DANGER

CAUTION

WARNING

We declare under our sole responsibility that this product corresponds to the regulations 2006/95/EC, 2004/108/

EC and 2011/65/EU and conforms with the standards or standardized documents: EN 61010-1, -2-010, -2-051; EN

61326-1 and DIN 12876-1.

24

Safety instructions

General information

•

Read the operating instructions completely before

starting up and follow the safety instructions.

• Keep the operating instructions in a place where it can be

accessed by everyone.

• Ensure that only trained staff work with the device.

• Follow the safety instructions, guidelines, occupational

health, safety and accident prevention regulations.

• Set up the device in a spacious area on an even, stable,

clean, non-slip, dry and fireproof surface.

• Do not operate the device in explosive atmospheres,

with hazardous substances.

• Protect the device and accessories from bumping and

impacting.

• Check the device and accessories for damage before

each use. Do not use damaged components.

• Safe operation is only guaranteed with the accessories

described in the ”

Accessories

” section.

• The socket for the mains cord must be easily accessible.

• Socket must be earthed (protective ground contact).

• The voltage stated on the type plate must correspond to

the mains voltage.

• The device can only be disconnected from the mains sup

-

ply by pulling out the mains plug or the connector plug.

• Disconnect the mains plug before attaching or changing

any accessories.

• Disconnect the mains plug before cleaning, mainte

-

nance or moving the circulator.

•

The device must only be opened by trained specialists,

even during repair. The device must be unplugged from

the power supply before opening. Live parts inside the

device may still be live for some time after unplugging

from the power supply.

Coverings or parts that can be re-

moved from the device without

the aid of any tools must be put

back on the device again to ensure safe operation, for

example to keep foreign objects and liquids, etc. from

getting into the device.

• The device may only be used as prescribed and as de

-

scribed in the operating instructions. This includes op-

eration by instructed specialist personnel.

• When using critical or hazardous materials in your pro

-

cesses,

IKA

®

recommends to use additional appropri-

ate measures to ensure safety in the experiment. For

example, users can implement measures that inhibit fire

or explosions or comprehensive monitoring equipment.

• Process pathogenic material only in closed vessels under

a suitable fume hood. Please contact

IKA

®

application

support if you have any question.

If the

OFF

switch is not within

reach when device is operating, an

EMERGENCY STOP

switch that

can be easily accessed must be installed in the work area.

• A laboratory circulator heats and circulates fluid accord

-

ing to specified parameters. This involves hazards due to

high temperatures, fire and general hazards due to the

device of electrical energy. The user is largely protect-

ed by the device of relevant standards. Further hazard

sources may arise due to the type of tempering fluid,

e.g. by exceeding or undercutting certain temperature

thresholds or by the breakage of the container and re-

action with the heat carrier fluid. It is not possible to

consider all eventualities. They remain largely subject to

the judgment and responsibility of the operator. For this

reason, it may become necessary for user to take other

precautionary safety measures.

• Insufficient ventilation may result in the formation of explo

-

sive mixtures. Only use the device in well ventilated areas.

The safety circuit (safe tempera-

ture) must be adjusted so that the

maximum permissible temperature

cannot be exceeded even in the event of a fault. Check

the safe temperature circuit on a regular basis (see sec-

tion "

Setting the safety temperature

").

• Securely fix the

IC basic

immersion circulator for use at

the bath, so that it cannot tip over.

• Use suitable hoses for connection.

• Secure hoses and tubes against slippage and avoid

kinks.

• Check hoses, tubes and bath at regular intervals for pos

-

sible material fatigue (cracks/leaks).

• When device is used for external circulation, extra pre

-

caution must be taken for hot liquid leakage due to

damaged hose.

• Mains cable should not get in contact with hot parts

and fluids.

• If you are using plastic bath, observe the permitted

working temperature range and fluids.

Do not start up the device if:

- It is damaged or leaking

- Cable (not only supply cable) is damaged.

• Be careful when filling a hot bath.

At high operating temperatures, the

temperature of housing parts, sur-

faces and tubes can exceed 70 ° C.

It is dangerous to touch the heater.

The temperature of the heater can

be very high.

DANGER

DANGER

WARNING

DANGER

WARNING

DANGER

25

• After a power failure during operation, the device may

start automatically (depending on operating mode).

• Transport the device with care.

• Do not transport or empty the bath while it is still hot.

This may result in accidents, especially scalding injuries.

Fluids

Only

use fluids, which fulfill the re

-

quirements for safety, health and

device compatibility. Be aware of

the chemical hazards that may be associated with the

bath fluid used. Observe all safety warnings for the fluids.

• Depending on the bath fluid used and the type of opera

-

tion, toxic or flammable vapors can arise. Ensure suit

-

able extraction.

• Do not use any fluid which may cause dangerous reac

-

tions during processing.

• Only use recommended bath fluid. Only use non-acid

and non corroding fluid.

Only process and heat up any fluid

that has a flash point higher than

the adjusted safe temperature limit

that has been set. The safe temperature limit must al-

ways be set to at least 25 ºC lower than the flash point

of the fluid used. Examine regularly the function of the

safety temperature limiter.

Never operate the device without

sufficient heat carrier fluid! You

should also be careful to ensure

that the minimum clearances and immersion depths in

the fluid are observed. Check the fluid level detection at

a regular basis (see the chapter "

Filling and draining

").

• Continuous monitoring of the bath and the filling level of

the bath fluid is required, especially at high temperatures.

• For optimum temperature stability, the fluids viscosity

should be 50 mm

2

/s or less at its lowest operating tem-

perature. This permits good fluid circulation and mini

-

mizes heating from the pump.

If water is used at higher tempera-

ture, there is heavy loss of fluid due

to the condensation of evapora-

tion steam.

• Untreated tap water is not recommended. It is recom

-

mended to use distilled water or high purity water (ion

exchangers) and add 0,1 g soda (sodium carbonate

Na

2

CO

3

) /liter, to reduce corrosive properties.

Risk of burning caused by vapor or

hot water at the outlet of the cool-

ing coil.

Do not use the cooling coil with

water at bath temperatures > 95°

C.

For bath temperatures > 60°C make

sure that the flow rate through the

cooling coil is high enough.

Don't use following fluids:

- Untreated tap water

- Concentration of acids or bases

- Solutions with halides: chlorides, fluorides, bromides,

iodides or sulfur

- Bleach (Sodium Hypochlorite)

- Solution with chromates or chromium salts

- Glycerine

- Ferrous water.

When changing the bath fluid

from water to a heat transfer fluid

for temperatures above 100 °C, re-

move the remaining water from the complete system

(including hoses and external devices). When doing this,

also open the stopper and union nuts caps of the pump

outputs and inputs and blow compressed air through

all the pump outputs and inputs! Beware of the risk of

burning due to delay in boiling!

CAUTION

DANGER

WARNING

DANGER

CAUTION

DANGER

DANGER

CAUTION

WARNING

Correct use

• Use

Use

IC

(

I

mmersion

C

irculator) and

HBC

(

H

eating

B

ath

C

irculator)

- For heating and circulating fluids

Intended Use: Tabletop Device

• Range of use (indoor use only)

- Laboratories

- Schools

- Pharmacies

- Universities

This device is suitable for use in all areas except:

- Residential areas

- Areas that are connected directly to a low-voltage supply

network that also supplies residential areas.

The safety of the user cannot be guaranteed:

- If the device is operated with accessories that are not

supplied or recommended by the

IKA

®

.

- If the device is operated improperly or in contrary to the

IKA

®

specifications.

- If the device or the printed circuit board are modified by

third parties.

26

Unpacking

• Unpacking

- Please unpack the device carefully

- In the case of any damage a detailed report must be sent

immediately (post, rail or forwarder).

Transport safety

- Remove the transport protection

under the

buoyage

(

4

). For

HBC

device,

you need to open the lid

(

16

) and remove the protection.

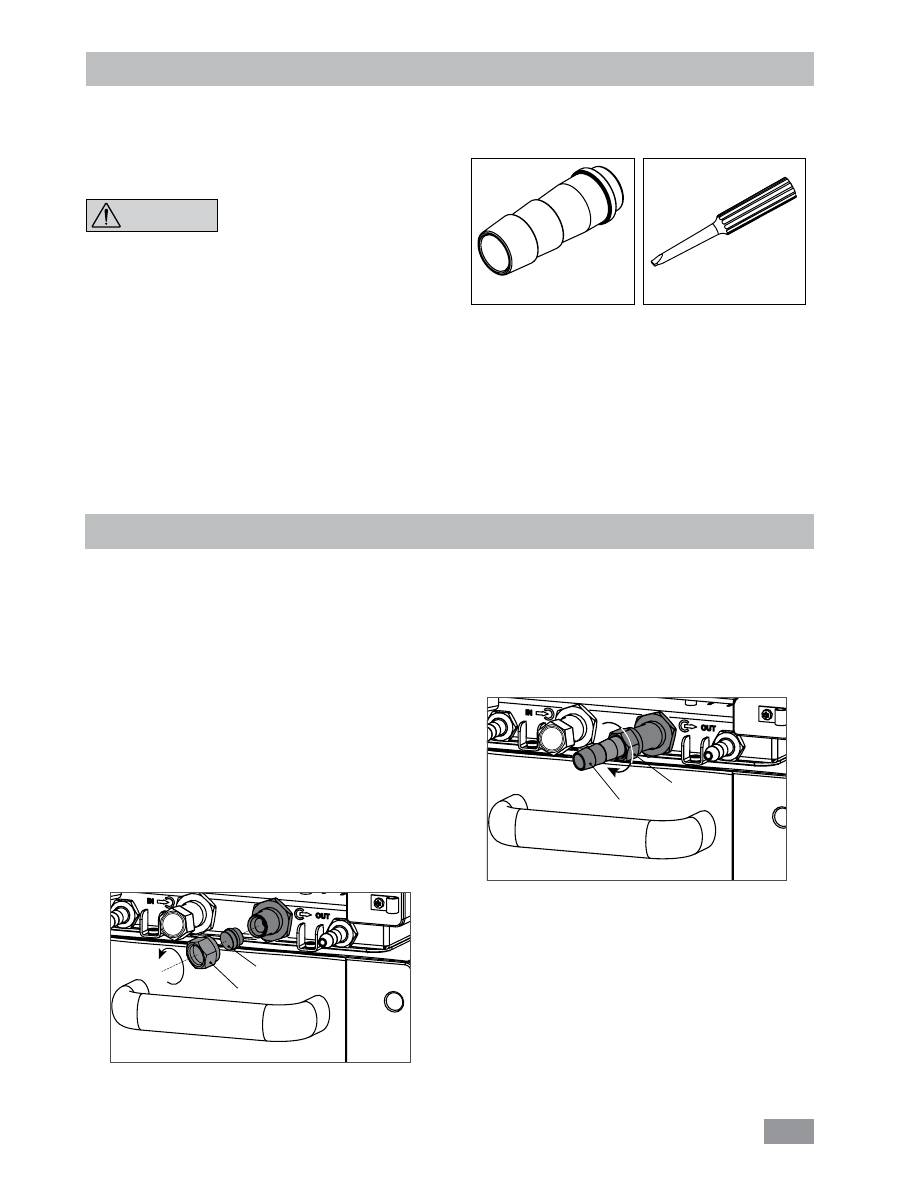

• Delivery scope

IC basic, HBC basic, HBC 10 basic

-

IC baisc

Immersion Circulator or

HBC 5 basic

Heating

Bath Circulator or

HBC 10 basic

Heating Bath Circulator

according to the order

- Mains cables

H 12

- Hose olive NW 12 (2 pieces)

see

Fig. 5

- Screwdriver (use for safety circuit)

see

Fig. 6

- Operating instructions

- Warranty card.

Preparations

• Setting up

- Place the device on an even, stable, clean, nonslip, dry

and fireproof surface.

- Keep at least 20 cm of open space at the front and

rear side.

- When a plastic bath is used, please ensure that the heat-

er does not contact the bath.

- The place for installation should be large enough and

provide sufficient air ventilation to ensure the room

does not warm up excessively because of the heat

from device radiates to the environment.

- Do not set up the device in the immediate vicinity of

heat sources and do not expose to sun light.

• Connecting the tubings

- Unscrew the union nuts and stoppers using a wrench

from the pump connection

IN (8)

and

OUT (9)

.

Fig. 6

Fig. 5

Additional for HBC 5 basic / HBC 10 basic:

- Temperature sensor Pt 100.30.

- Connect the hoses for circulating the external system to

the pump connectors

M 16 x 1

for

IN

and

OUT

directly

or with the olives.

- Screw the hose olive to the pump connection

IN

and

OUT

with union nuts. Slide the hoses (NW 12) onto the

olives. The hoses must be secured with suitable clamps.

Note:

Please note the permissible temperature range of hos-

es. For hot fluids we recommend the

IKA

®

LT 5.20

hoses.

When the external system is not necessary, please seal the

pump connectors

IN

and

OUT

with the existing union

nuts and stoppers.

Stopper

Union nut

Hose olive

Union nut

Fig. 7

Fig. 8

CAUTION

27

Fig. 10

Fig. 11

Low Level

High Level

WARNING

•

Fluids

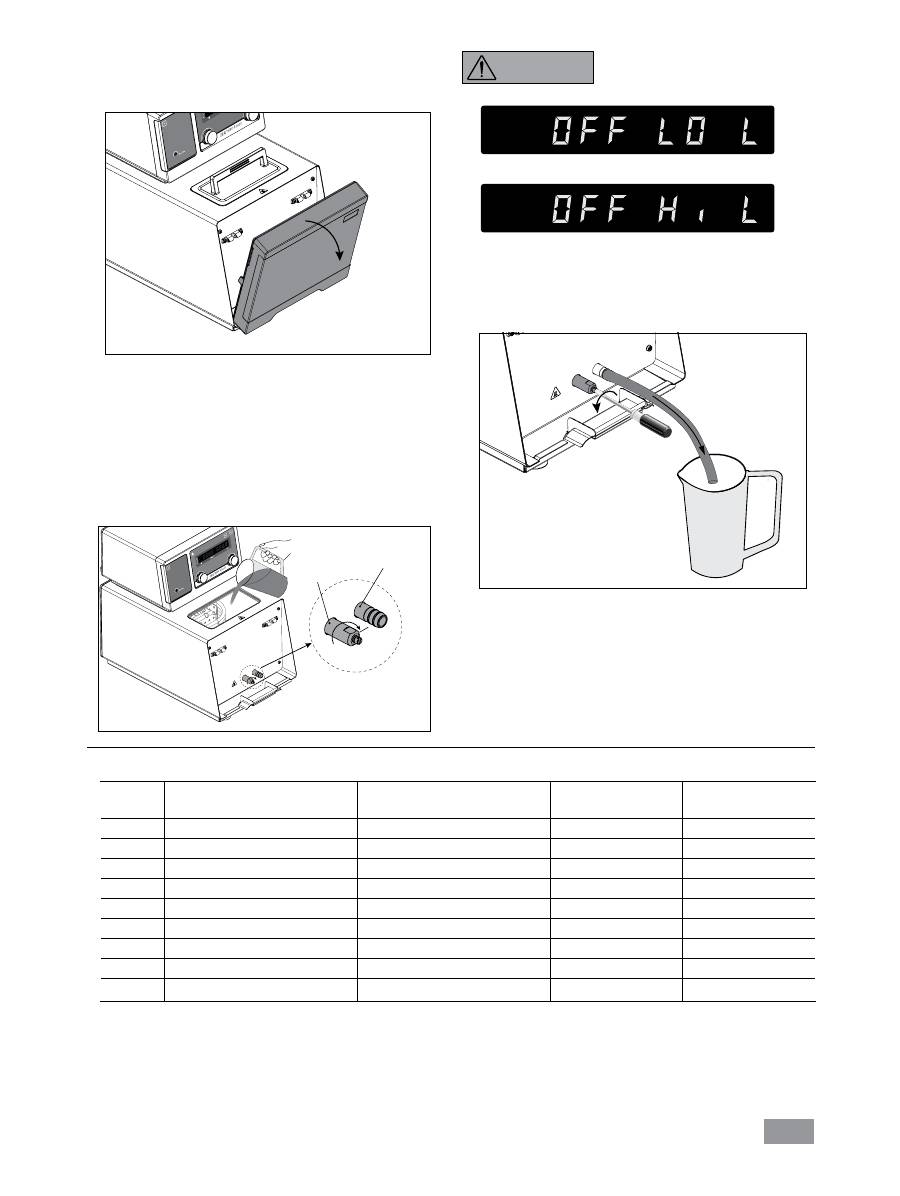

No.

IKA

®

Designation

Operating temperature range

(

°C

)

Safety temperature

(

°C

)

Flash point

(

°C

)

0

EG19_N10.100 (H

2

0 + Glycole)

-10 ... 100

100

125

1

EG34_N20.100 (H

2

0 + Glycole)

-20 ... 100

100

125

2

EG40_N25.100 (H

2

0 + Glycole)

-25 ... 100

100

125

3

EG45_N30.100 (H

2

0 + Glycole)

-30 ... 100

100

125

4

SI_P20.275 (Silcone Oil)

20 ... 275

275

300

5

SI_N30.145 (Silicone Oil)

-30 ... 145

145

170

6

SY_N10.100 (Synthetic Oil)

-10 ... 100

100

125

7

Water*

5 ... 95

95

—

8

Customized

*

Note:

Tap water may be unsuitable for operation because the calcium carbonate content may cause calcification.

High purity water (from icon exchangers) and distilled or bi-distilled water are unsuitable for operation due to corrosive

properties of these media. High purity water and distillates are suitable as a medium after adding 0,1 g soda (Na

2

CO

3

,

sodium carbonate) per liter of water.

Fig. 9

• Filling and draining

- Before filling the fluid into the bath, open the front

cover as indicated in following figure.

- Check and make sure that the drain valve is closed (the

stop position in clockwise direction, see

Fig. 10

).

Note:

Please note information in chapter “

Commis-

sioning

”.

- Connect the mains plug and turn on the device with

mains switch (

2

).

- The low level warning message appear on the display.

- Open the lid (

16

) and fill fluid to the bath.

Note:

Pay attention to the fluid

level information on the display:

- To drain the fluid from the bath, connect a hose to the

drain port and turn the drain valve in counter clockwise

direction with a straight screwdriver.

Drain valve

Drain port

Stop position

28

• Cooling coil

When the set temperature is close to the ambient tem-

perature, the cooling coil should be used for counter-

cooling due to the self-heating.

Connect the water supply and return line hoses to the

cooling coil connectors (see

Fig. 4

).

For bath temperatures > 95 °C do not use the cooling coil

with water.

For bath temperatures > 60 °C make sure that the flow

rate through the cooling coil is high enough, to avoid

excessive calcification.

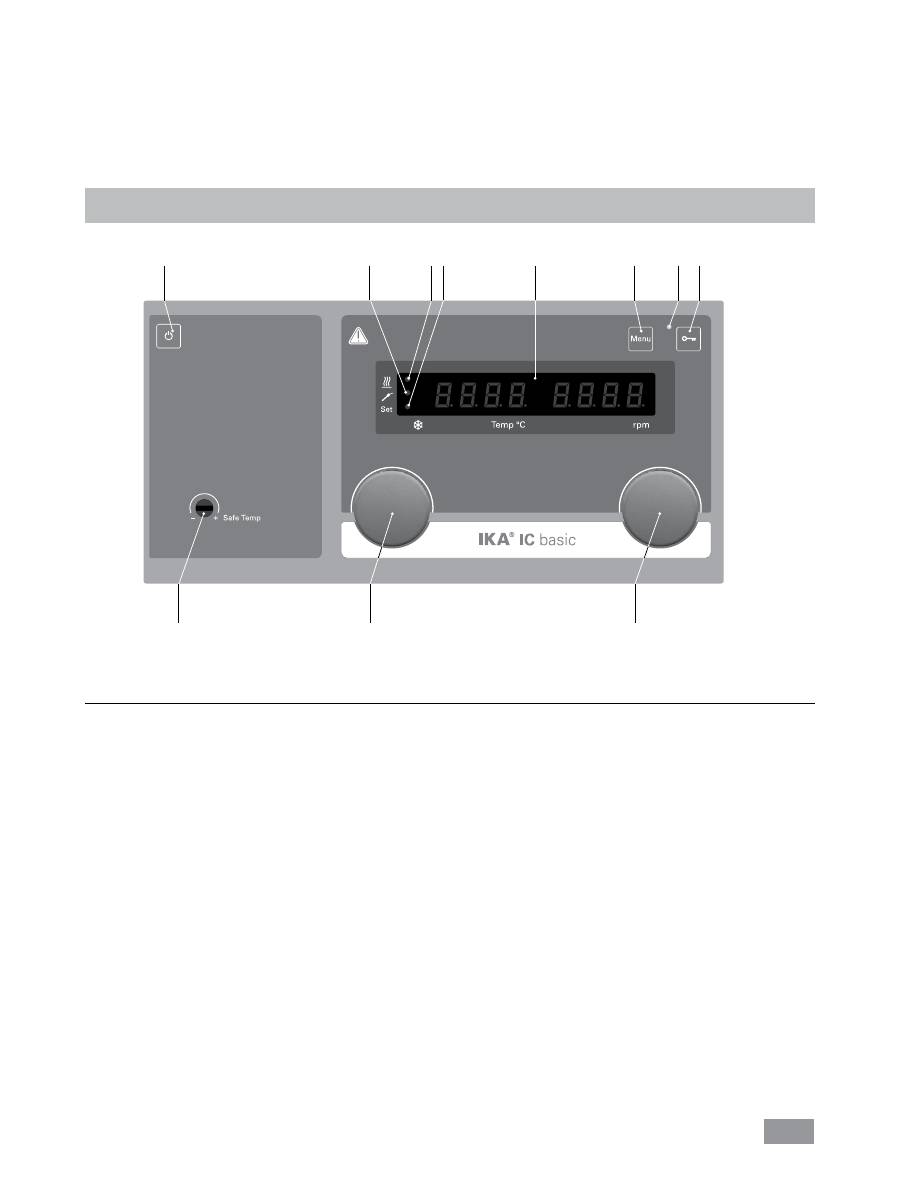

Operator panel and display

B

C

A

D

K

J

I

G

E

M F

Fig. 12

Item Designation

Function

A

ON/OFF button:

Switch on/off the circulator.

B

Rotating/pressing knob:

Set the temperature value.

Start/stop the heating function.

Navigation, selecting the settings in the menu.

C

Rotating/pressing knob:

Set the pump speed value.

Start/stop the pump function.

Set and confirm the menu options.

D

Adjustable safety circuit:

Adjust the safety temperature limit with delivered screwdriver.

E

Menu button:

Press it once: menu option is display.

Press it a second time: back to the working screen.

F

Key button:

Lock/unlock keys and knobs.

G

LED display:

Display the settings and actual values.

I

LED, heater:

Indicate the heating function is activated.

J

LED, temperature sensor:

Indicates that an external temperature sensor is connected.

K

LED, set:

The LED lights up at the same time as the set value is displayed.

M

LED

,

key button

Indicates that the function of keys and knobs is deactivated.

29

Commissioning

Check whether the voltage specified on the type plate

matches the mains voltage available.

The power socket used must be

earthed (protective earthing).

If above conditions are met, the device is ready for opera-

tion after plugging in the mains plug.

If these conditions are not met, safe operation is not guar-

anteed and the device could be damaged.

Observe the ambient conditions (temperature, humidity,

etc.) listed under “

Technical Data

”.

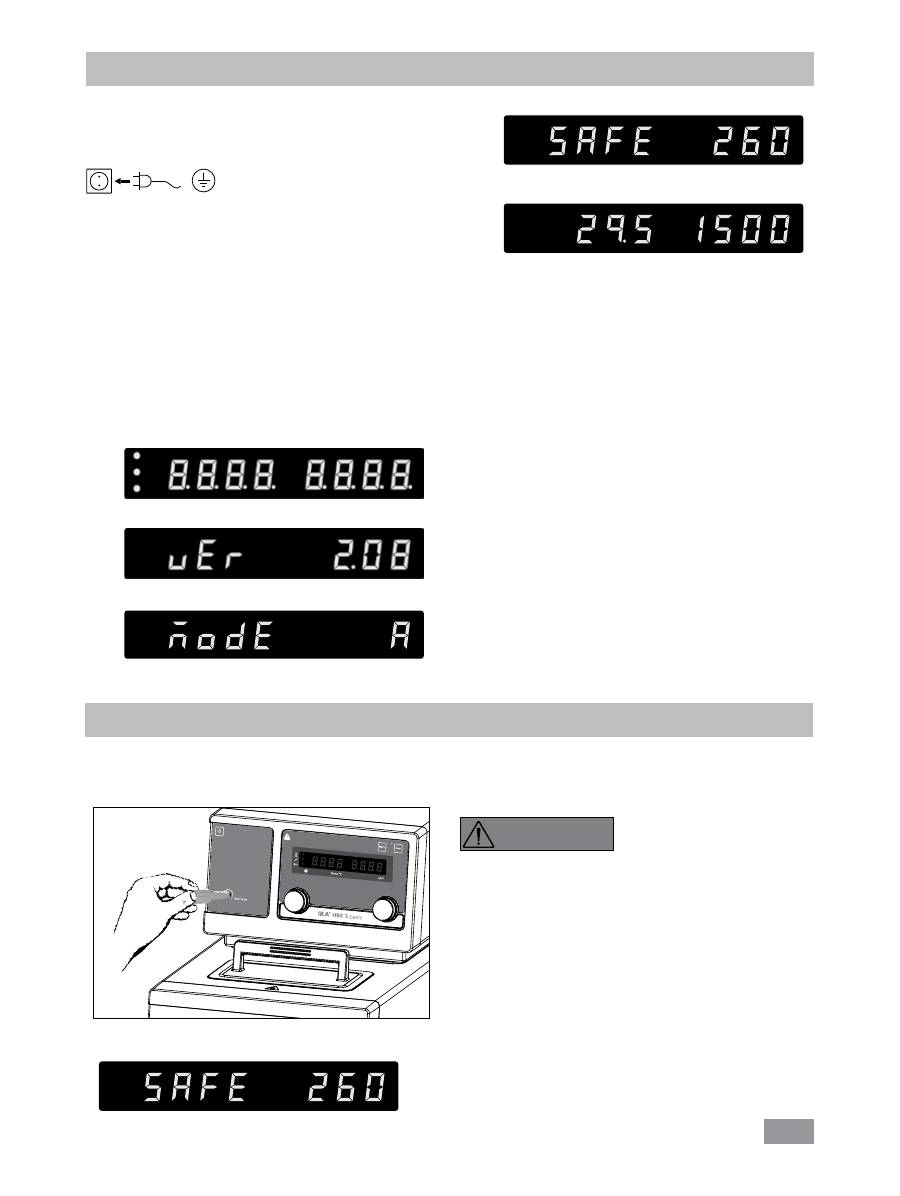

After switching on the mains switch (

2

) at the back of the

device or pressing the power key (

A

), all LED segments

light up during the self test. Then the software version,

operating mode, safety temperature and working settings

will be shown.

Then the device enters standby status and is ready for op-

eration.

Change the temperature setting with left knob (

B

).

Change the pump speed setting with the right knob (

C

).

Press the left knob (

B

) in standby status. The device start

heating function, meanwhile the pump start to run.

Press the right knob (

C

) in working status to stop the pump

function. The heating function and pump stops.

Note:

In standby status,

press the right knob (

C

) to start

the pump function. The heating function will not be ac-

tivated.

In working status, press the left knob (

B

) to stop the heat-

ing function, the pump keep running.

Setting the safety temperature

Adjust the safety temperature with screwdriver delivered

with the device.

The safety temperature setting will appear on the display.

DANGER

Factory setting: approximate max. value

Adjustment range: 0

–

260 °C

Note:

The safety temperature

must always be set to at least

25 ºC lower than the flash point

of the fluid used.

Safety temperature (safe)

Fig. 13

Software version (ver)

Safety temperature (safe)

Working setting

Starting

Operating mode (mode)

HBC 5

30

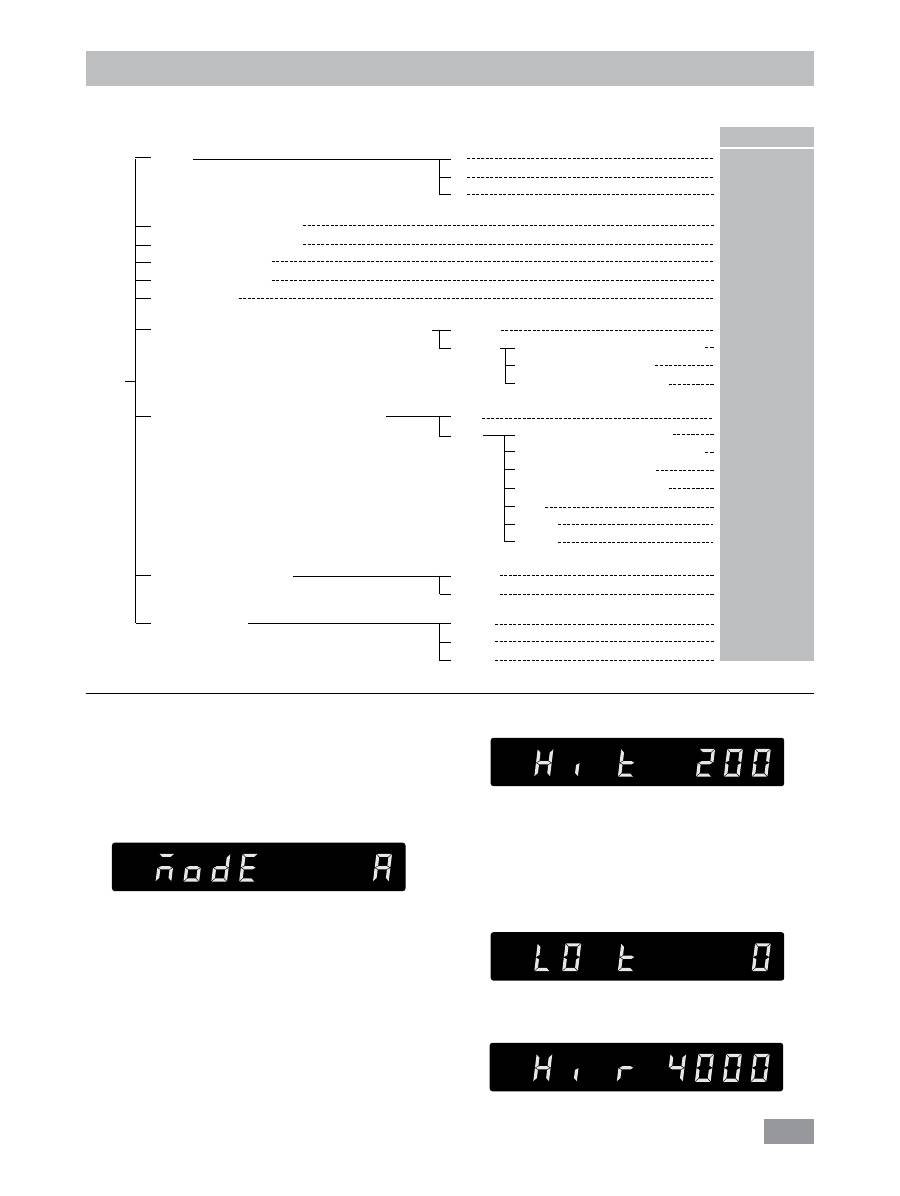

Menu settings

MODE

Maximum temperature (HI T)

Minimum temperature (LO T)

Maximum speed (HI R)

Minimum speed (LO R)

Fluid type (FLUI)

The type of temperature PID control arithmetic (AUTO)

External and internal temperature control (ET)

Alarm and key tone (BEEP)

Calibration (CALI)

Menu

•

Menu structure

Default settings

A

B

C

Proportional coefficient of PID (Kp 1)

Integrate time of PID (Ti 1)

Differential time of PID (Td 1)

AUTO 1

AUTO 0

External sampling time (EuT 2)

Proportional coefficient of PID (Kp 2)

Integrate time of PID (Ti 2)

Differential time of PID (Td 2)

DF t

FASt 0

FASt 1

ET 0

ET 1

BEEP 0

BEEP 1

CALI 0

CALI 2

CALI 3

activated

-

-

200 °C

0 °C

4000 rpm

1000 rpm

0

-

15,0

5,00

5,0

activated

120 s

1,0

1,5

0,0

100,0

-

activated

-

activated

activated

-

-

•

Basic guide to setting the menu options:

F

Enter the menu by pressing ”Menu” key (

E

).

F

Turn the left knob (

B

) to select a menu option.

F

Turn the right knob (

C

) to change the menu value settings.

F

Confirm the menu settings by pressing the right knob (

C

).

•

Operating mode (MODE)

Mode A:

After power on/power failure no automatic

restart of functions.

Mode B:

After power on/power failure automatic re-

start of functions, depending on previous settings.

Mode C:

Set values (set in A or B) cannot be changed.

After power on/power failure automatic restart of func-

tions, depending on previous settings.

•

Maximum temperature (HI T)

The maximum adjustable value: 200° C. This value can

be limited additionally by the selected liquid (No., see

“

Settings

” fluid type).

Note:

The maximum value is limited by the set safety

temperature.

•

Minimum temperature (LO T)

The minimum adjustable value: 0° C

•

Maximum speed (HI R)

The maximum adjustable value: 4000 rpm.

31

•

Minimum speed (LO R)

The minimum adjustable value: 1000 rpm

•

Fluid type

(

FLUI

)

The chosen fluid (No.) of the temperature setting is lim

-

ited. See Section “

Fluid

”.

•

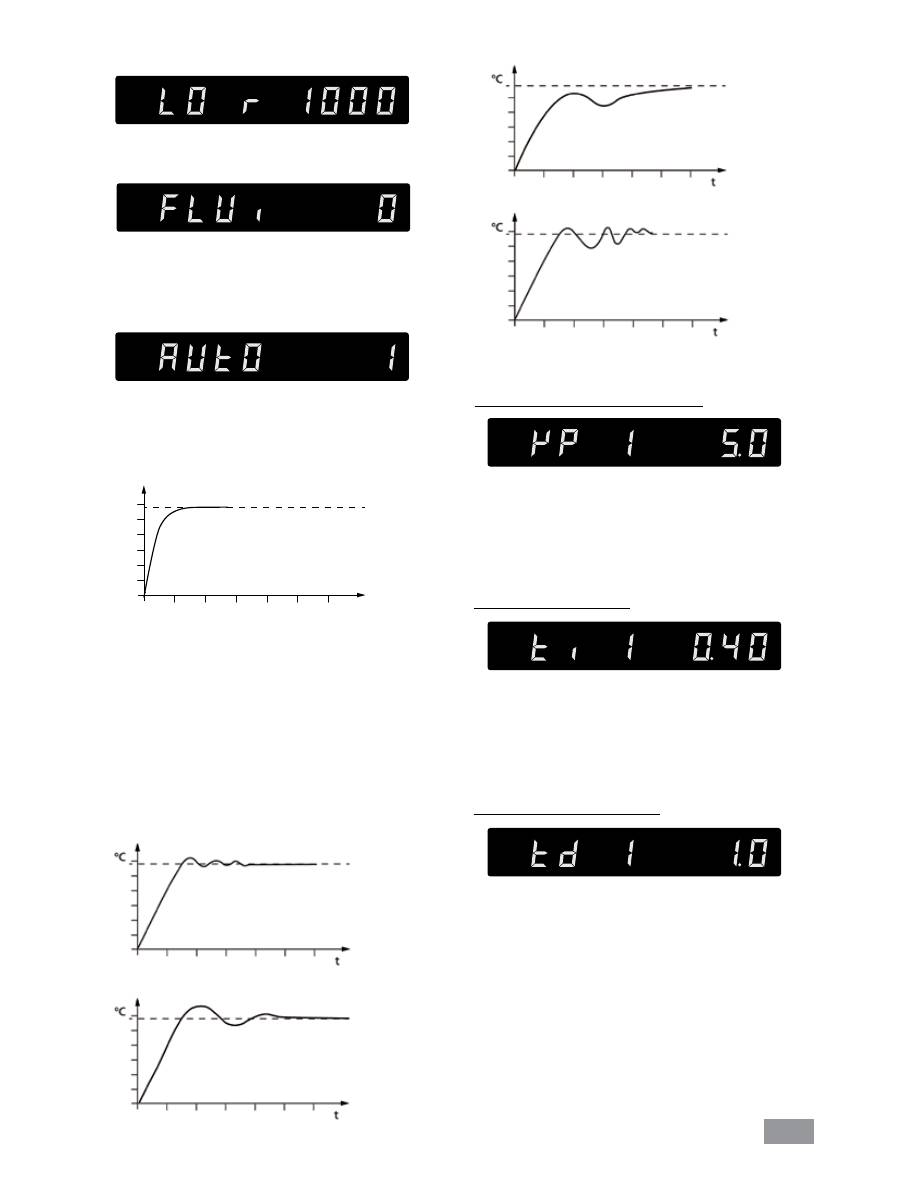

Temperature control type (AUTO)

AUTO 1:

AUTO 1

is the default setting. The optimum settings are

determined automatically.

Heat-up curve in auto-tuning control (

AUTO 1

):

Fig. 15

°C

t

Proportional coefficient of PID (

Kp 1

)

Integral time of PID (

Ti 1

)

Differential time of PID (

Td 1

)

Fig. 14

The proportional coefficient

Kp

is the controller ampli-

fication and determines how strongly the control devia-

tion (the difference between the target temperature and

actual temperature) directly affects the control variable

(on-time of the heater).

Kp

values that are too large can

lead to the controller overshooting.

The integral time

Ti (s)

is the correction time and deter-

mines how strongly the duration of the control devia-

tion affects the control variable.

Ti

compensates an ex-

isting control deviation. A high

Ti

means a smaller and

slower effect on the control variable.

Ti

values that are

too small can lead to instability of the controller.

The differential time

Td (s)

is the derivative time and de-

termines how strongly the rate of change of the control

deviation affects the control variable.

Td

compensates

for rapid control deviations. A high

Td

means a smaller

and slower effect on the control variable.

Td

values that

are too small can lead to instability of the controller.

AUTO 0:

For special requirements,

AUTO 0

can be used with

manual adjustment of the control parameters.

If the PID control (

AUTO 0

) option is selected, the fol-

lowing items including

Kp 1

,

Ti 1

and

Td 1

could be

set. Otherwise they are not displayed in the menu list.

Note:

Inappropriate settings may produce the follow-

ing heat-up curves:

Kp too high

Ti too low

Td too high

Kp too low

Ti too high

32

•

External and internal temperature control (ET)

ET 0:

internal temperature control

ET 1:

external temperature control

If the external temperature control (

ET 1

) is selected,

the following items

EuT 2

(sampling time),

Kp 2

,

Ti 2

,

Td 2

,

Df t

(maximum temperature difference between

internal and external temperature) and

FAST

could be

set. Otherwise they are not displayed in the menu list.

The sampling time

EuT 2

(s) is the interval over which

the external control deviation and the respective con-

trol variable (dependent on

Kp 2

,

Ti 2

,

Td 2

,

Df t

and

FAST

) is determined.

EuT 2

must be adjusted to match the response charac-

teristic (total of all time constants) of the external closed

loop controlled system, so that the control variable can

deliver a uniform and measurable change in the control

deviation.

EuT 2

values that are too small or too large

can lead to instability of the controller.

Dynamics of the external PID temperature control (

FAST

)

FAST=0:

accurate, without overshoot

FAST=1:

fast, with overshoot

•

Alarm and key tone (BEEP)

BEEP 0:

no alarm and key tone

BEEP 1:

alarm and key tone is activated

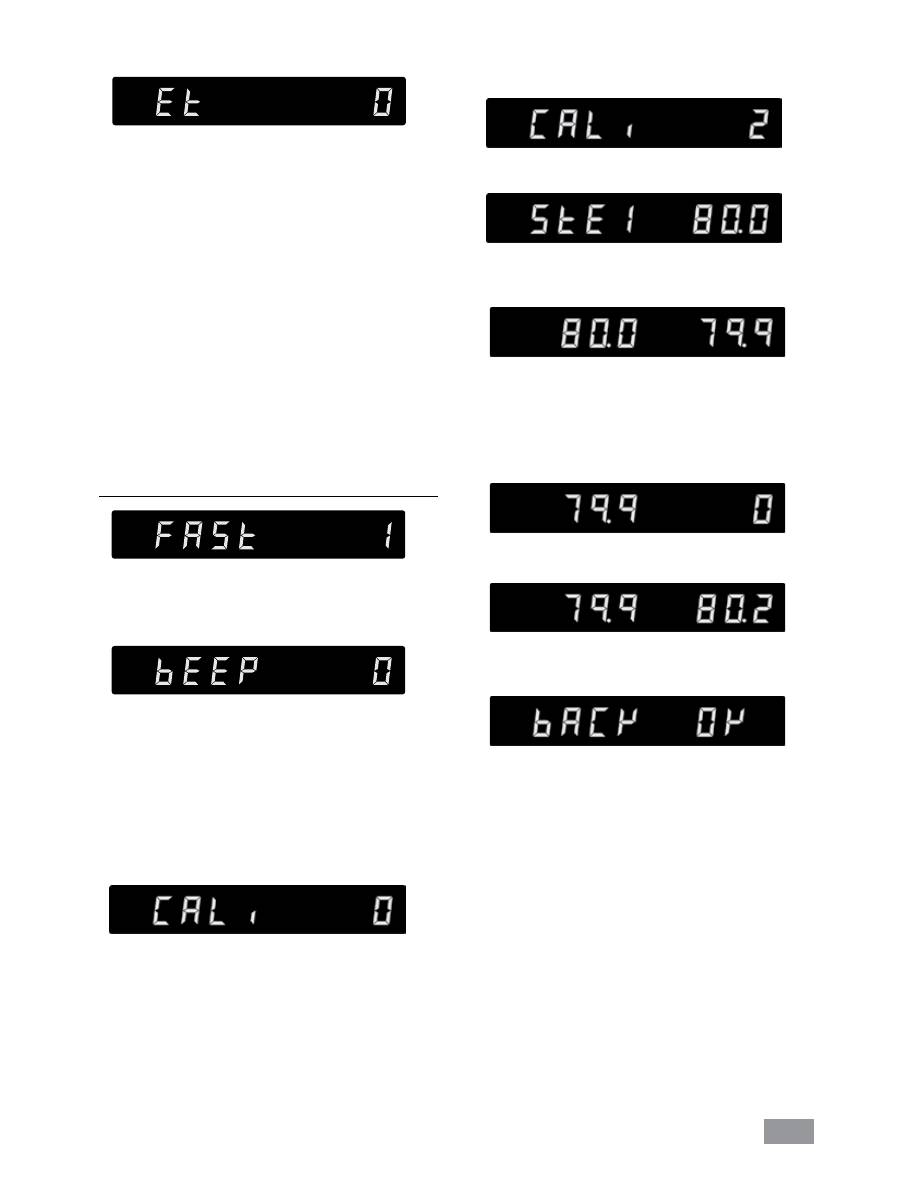

•

Calibration and adjustment (CALI)

CALI 0:

no calibration

CALI 2:

2-point calibration

CALI 3:

3-points calibration

Example: 2-point calibration:

Dip the temperature sensor of the reference measuring

instrument into the bath fluid:

- If

ET 0

: into the internal bath (open the lid (

16

))

- If

ET 1

: at the same position as the external Pt100

temperature sensor (

12

).

Set the first point temperature (e.g. 80 °C). Confirm the

setting by pressing the right knob (

C

).

Left area of the display appears the set value (80 °C) and

the right area of the display appears the actual tempera-

ture value measured. The set LED (

K

) flashes briefly.

The unit now starts and controls to the set value. When

the temperature has reached the set value and has be-

come constant, the “Set” LED (

K

) no longer flashes and

the following display appears.

The temperature measured by the unit appears on the

left hand side.

Input the calibration value from the reference mesuring

instrument (e.g. 80.2 °C) with the right knob (

C

).

Confirm the value by pressing the right knob (

C

).

Back to previous screen for input a new value by press-

ing the left knob (

B

).

Back

OK

The first point calibration is finished now.

Calibration of the other points is performed in the same

way.

If

ET 0

: adjustment of the internal temperature mea-

surement.

If

ET 1

: adjustment of the external temperature mea-

surement.

Select 2-point calibration in the menu. Press the right

knob (

C

) to start the 2-point calibration.

33

Interface and output

The device can be operated in “Remote” mode via the RS 232

interface (

10

) or the USB interface (

11

) connected to a PC

and with the laboratory software Labworld

soft

®

.

Note:

Please comply with the system requirements to-

gether with the operating instructions and help section

included with the software.

USB interface

The Universal Serial Bus (USB) is a serial bus for connect-

ing the device to the PC. Equipped with USB devices can

be connected to a PC during operation (hot plugging).

Connected devices and their properties are automatically

recognized. The USB interface can also be used to update

firmware.

USB device drivers

After the device is connected to the PC through the USB

cable, it tells the Windows operating system with which

device drivers are required.

Windows operating system will then either:

- load the driver

- install the driver if it is not already installed

- require manual installation, select:

http://www.ika.net/ika/lws/download/stmcdc.inf

The data communication is via a virtual COM port.

Configuration, command syntax and commands of the vir-

tual COM ports are as described in RS 232 interface.

RS 232 interface

Configuration

- The functions of the interface connections between the

stirrer machine and the automation system are chosen

from the signals specified in EIA standard RS 232 in ac-

cordance with DIN 66 020 Part 1.

- For the electrical characteristics of the interface and the

allocation of signal status, standard RS 232 applies in ac-

cordance with DIN 66 259 Part 1.

- Transmission procedure: asynchronous character trans-

mission in start-stop mode.

- Type of transmission: full duplex.

- Character format: character representation in accordance

with data format in DIN 66 022 for start-stop mode. 1

start bit; 7 character bits; 1 parity bit (even); 1 stop bit.

- Transmission speed: 9600 bit/s.

- Data flow control: none

- Access procedure: data transfer from the stirrer machine to

the computer takes place only at the computer’s request.

Command syntax and format

The following applies to the command set:

- Commands are generally sent from the computer (Master)

to the device (Slave).

- The device sends only at the computer’s request. Even

fault indications cannot be sent spontaneously from the

device to the computer (automation system).

- Commands are transmitted in capital letters.

- Commands and parameters including successive parame-

ters are separated by at least one space (Code: hex 0x20).

- Each individual command (incl. parameters and data)

and each response are terminated with Blank CR LF

(Code: hex 0x20 hex 0x0d hex 0x20 hex 0x0A) and have

a maximum length of 80 characters.

- The decimal separator in a number is a dot (Code: hex

0x2E).

The above details correspond as far as possible to the rec-

ommendations of the NAMUR working party (NAMUR rec-

ommendations for the design of electrical plug connections

for analogue and digital signal transmission on individual

items of laboratory control equipment, rev. 1.1).

The NAMUR commands and the additional specific

IKA

®

co mmands serve only as low level commands for commu-

nication between the device and the PC. With a suitable

terminal or communications programme these commands

can be transmitted directly to the circulator equipment. The

IKA

®

software package, Labworld

soft

®

, provides a conve-

nient tool for controlling circulating equipment and collect-

ing data under MS Windows, and includes graphical entry

features, for pump motor speed ramps for example.

The following table summarizes the (NAMUR) commands

understood by the

IKA

®

control equipment.

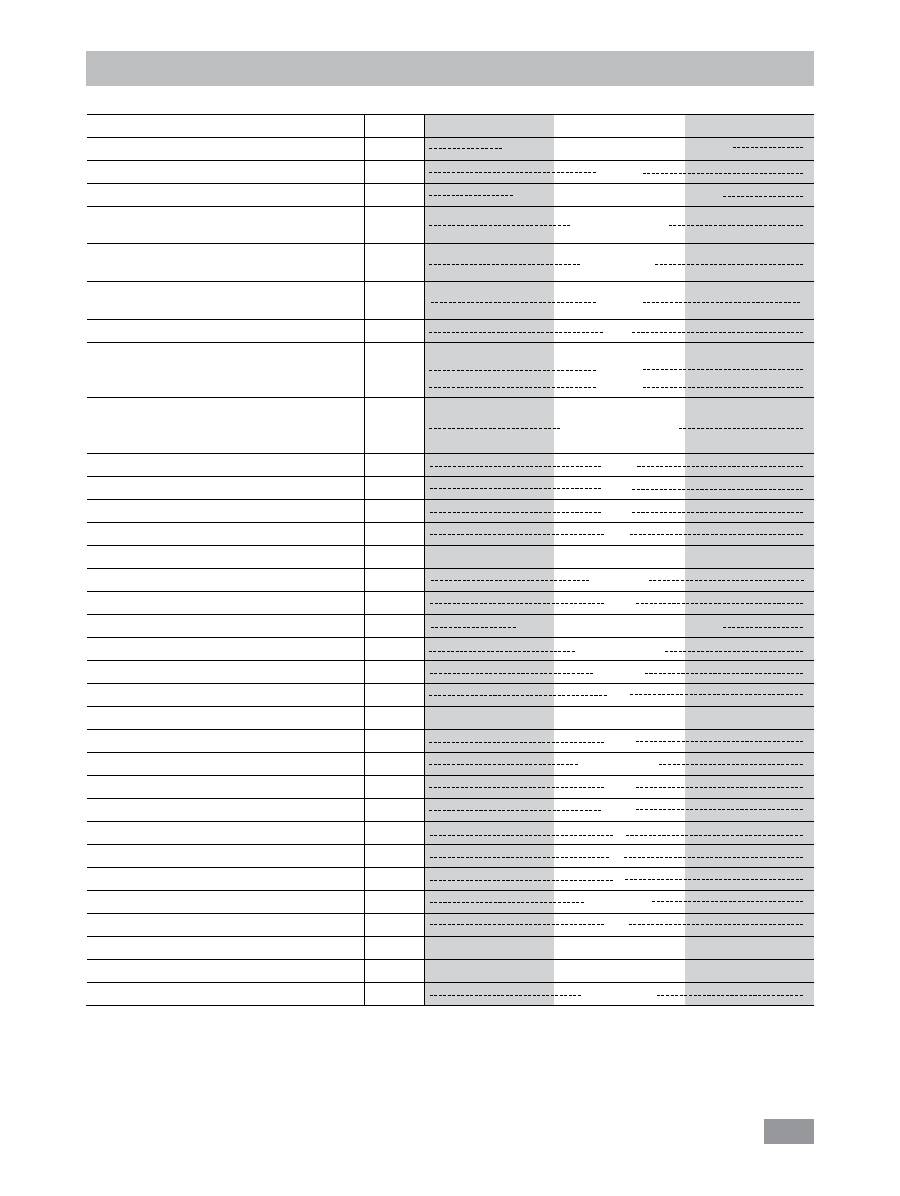

Commands

NAMUR

Commands

Function

IN_PV_1

Read the external actual temperature

IN_PV_2

Read the internal actual temperature

IN_PV_3

Read the safety actual temperature

IN_PV_4

Read the pump actual speed

IN_SP_1

Read the internal setting temperature (if ET=0)

Read the external setting temperature (if ET=1)

IN_SP_3

Read the safety setting temperature

IN_SP_4

Read the pump setting speed

34

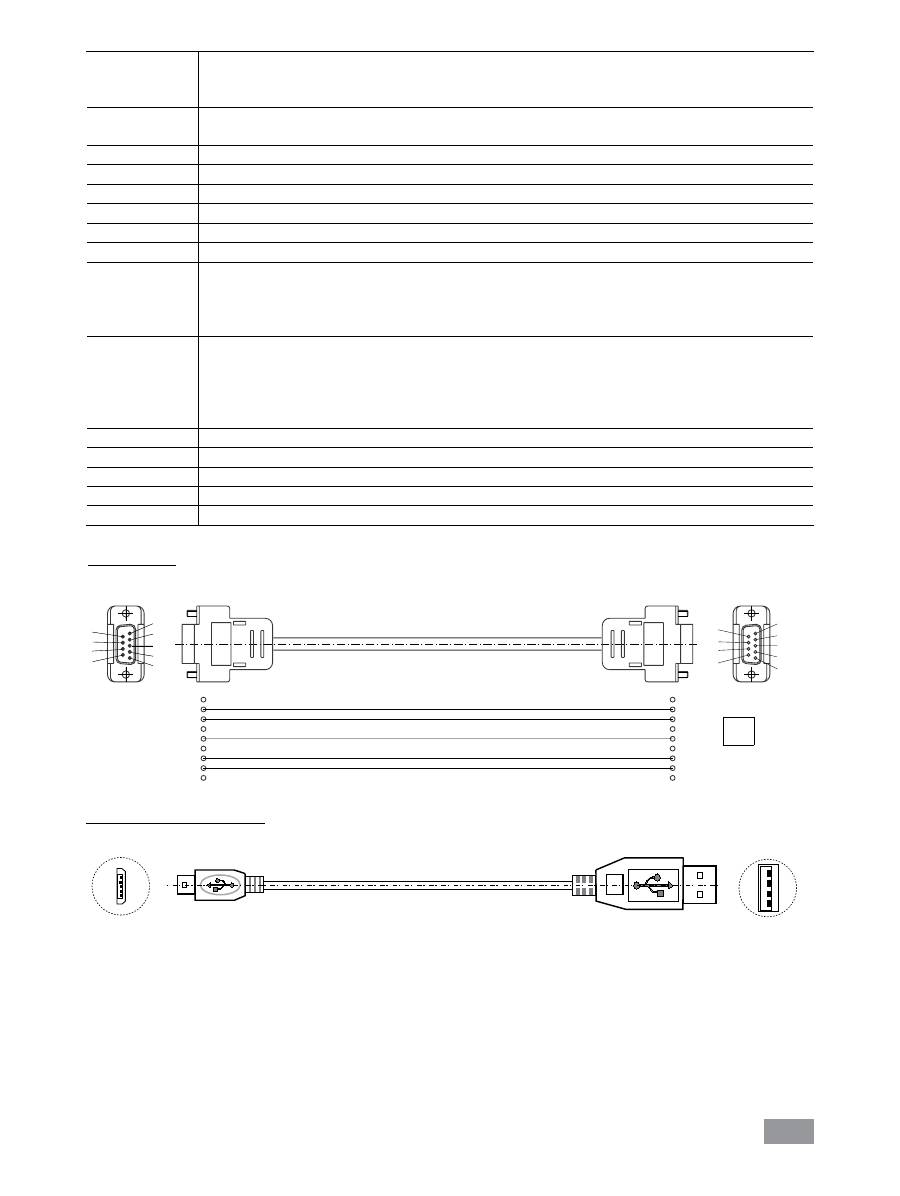

PC 1.1 Cable

This cable is required to connect RS 232 port (

10

) to a PC.

1

2 RxD

3 TxD

4

5 GND

6

7 RTS

8 CTS

9

1

RxD 2

TxD 3

4

GND 5

6

RTS 7

CTS 8

9

PC

1

2

3

4

5

6

7

8

9

9

8

7

6

5

4

3

2

1

Fig. 16

USB cable A - Micro B 2.0

This cable is required to connect USB port (

11

) to a PC.

USB micro B

USB A

A

Fig. 17

IN_TMODE

Read temperature control

0: internal regulation

1: external regulation

OUT_SP_1 xxx

Set the internal setting temperature XXX (if ET=0)

Set the external setting temperature XXX (if ET=1)

OUT_SP_12@n

Set the WD safety temperature with echo of the set (defined) value.

OUT_SP_4 xxx

Set the pump speed XXX

OUT_SP_42@n

Set the WD-safety speed with echo of the set (defined) value.

IN_STATUS

Status bits

OUT_TMODE_0

Set to Internal temperature control

OUT_TMODE_1

Set to External temperature control

OUT_WD1@n

Start the watchdog mode 1 and set the time for the watchdog to n (20...1500) seconds.

Echo of the Watchdog time.

During a WD1-event, the heating and pump functions are switched off.

This command needs to be send within the watchdog time.

OUT_WD2@n

Start the watchdog mode 2 and set the watchdog time to n (20...1500) seconds.

Echo of the watchdog time.

During a WD2-event, the set temperature is changed to the WD safety temperature and the pump set

speed is set to the WD safety speed.

This command needs to be send within the watchdog time.

RESET

Reset the PC control and stop the device functions.

START_1

Start the heating function

START_4

Start the pump function

STOP_1

Stop the heating function

STOP_4

Stop the pump function

35

Maintenance and cleaning

The device is maintenance-free. It is only subject to the

natural wear and tear of components and their statistical

failure rate.

Cleaning

For cleaning disconnect the mains

plug!

Use only cleaning agents which have been approved by

IKA

®

to clean

IKA

®

devices.

Dirt

Cleaning agent

Dye

Isopropyl alcohol

Construction material

Water containing tenside/

isopropyl alcohol

Cosmetics

Water containing tenside/

isopropyl alcohol

Foodstuff

Water containing tenside

Fuel

Water containing tenside

For materials which are not listed, please request

information from IKA

®

application support.

Wear protective gloves while cleaning the device.

Electrical devices may not be placed in the cleansing agent

for the purpose of cleaning.

Do not allow moisture to get into the device when cleaning.

Before using another than the recommended method for

cleaning or decontamination, the user must ascertain with

IKA

®

that this method does not damage the device.

Spare parts order

When ordering spare parts, please give:

- machine type

- manufacturing number, see type plate

- item and designation of the spare part,

see

www.ika.com

, spare parts diagram and list

- Software version.

Repair

Please send the device for repair only after it has

been cleaned and is free from any materials which

may constitute a health hazard.

For repair, please request the “

Decontamination Clear-

ance Certificate

” from

IKA

®

, or download printout of it

from the

IKA

®

website

www.ika.com

.

If you require servicing, return the device in its original

packaging. Storage packaging is not sufficient. Please also

use suitable transport packaging.

36

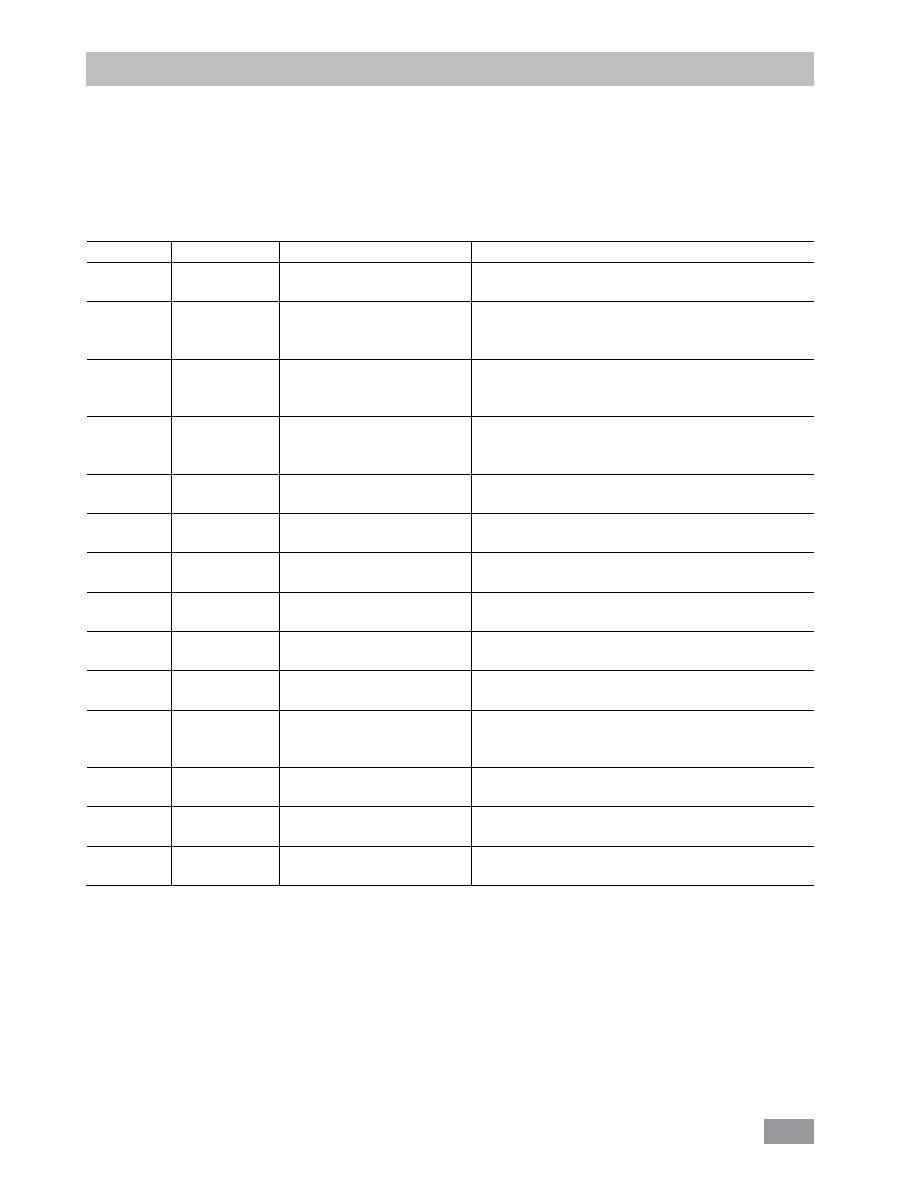

Error codes

Any malfunctions during operation will be identified by an error message on the display.

Proceed as follows in such cases:

F

Switch off device using the main switch at the back of the device

F

Carry out corrective measures

F

Restart device

Error code

Effect

Cause

Solution

Err 01

Pump off

Heating off

No External Pt 100 temperature

sensor

- Check this sensor

Err 02

Pump off

Heating off

Motor Over current (rate

current)

- Reduce pump motor speed

- Use fluid with lower viscosity

- Check if the pump impeller is blocked

Err 03

Pump off

Heating off

Motor Over current (Max

current)

- Reduce pump motor speed

- Use fluid with lower viscosity

- Check if the pump impeller is blocked

Err 04

Pump off

Heating off

Motor Hall signal missing

- Reduce pump motor speed

- Use fluid with lower viscosity

- Check if the pump impeller is blocked

Err 05

Pump off

Heating off

Too high liquid level

- Check the liquid level and buoyage

Err 06

Pump off

Heating off

Too low liquid level

- Check the liquid level and buoyage

Err 07

Pump off

Heating off

Too high voltage

- Check the mains power

Err 08

Pump off

Heating off

Too low voltage

- Check the mains power

Err 09

Pump off

Heating off

Device internal temperature is

too high

- Check the ambient temperature and let the device

cool down

Err 10

Pump off

Heating off

PC communication failure

- Check communication cable

Err 11

Pump off

Heating off

Temperature difference

between control sensor and

safety sensor is too much

- Check safety temperature circuit and bath fluid

Err 12

Pump off

Heating off

Safety temperature alarm

- Check the bath temperature measurement

Err 13

Pump off

Heating off

Heater switched off by safety

circuit

- Check safety temperature set value, fluid level

Err 14

Pump off

Heating off

Fan error

- Check the fan and clean the grids at the rear side

If the actions described fails to resolve the fault or another error code is displayed then take one of the following steps:

- Contact the service department;

- Send the device for repair, including a short description of the fault.

37

Accessories

IC basic

HBC 5 basic

HBC 10 basic

Water bath protective media

AQ.1

Aquacide 1

•

•

•

Tubing and hoses

LT 5.20

metal hose (isolated M16 x 1)

•

•

•

H.PVC.8

PVC hose (nominal width 8)

•

•

•

H.PVC.12

PVC hose (nominal width 12)

•

•

•

H.SI.8

silicone hose (nominal width 8)

•

•

•

H.SI.12

silicone hose (nominal width 12)

•

•

•

H.PTFE.8

PTFE hose (nominal width 8)

•

•

•

H.PTFE.12

PTFE hose (nominal width 12)

•

•

•

Tubing Insulations

ISO. 8

insulation (8 mm)

•

•

•

ISO.12

insulation (12 mm)

•

•

•

Bath vessels

IB pro 12

stainless steel bath

•

IB pro 20

stainless steel bath

•

Bridges and Covers

BS.IC

small bridge (for

IB pro 12

,

IB pro 20

)

•

CM.IC

medium cover (for

IB pro 12

)

•

CL.IC

large cover (for

IB pro 20

)

•

Additional accessories

RV 10.5003

pressure regulating valve

•

•

•

RV 10.5002

filter

•

•

•

Pt 100.30

temperature sensor

•

PC 1.1

cable (RS 232)

•

•

•

USB Kabel A - Micro B 2.0

•

•

•

CC 1

Cooling coil

•

LT 5.24

hose adapter

•

•

•

Labworld

soft

®

•

•

•

See more accessories on

www.ika.com.

38

Technical data

IC basic

HBC 5 basic

HBC 10 basic

Nominal voltage

VAC

230 ±10% (EURO) / 115 ±10% (USA)

Frequency

Hz

50/60

Max. input power

W

2650 (230 VAC)/1400 (115 VAC)

Working temperature range

(RT+10 at 1000rpm)

°C

RT + 10 ... 200

Operating temperature range

(with forced cooling)

°C

-20 ... 200

Temperature stability – Internal temperature

control 70°C, water (according to DIN12876)

K

± 0,02

Temperature control

PID

Temperature measurement, absolute accuracy

Internal (int) (adjustable by calibration)

External (ext) (adjustable by calibration)

K

K

± 0,2

± 0,2

External Pt 100.5 temperature sensor tolerance

to DIN EN 60751 class A, ≤ ± (0.15 + 0.002 x |T|),

e.g. at max. 100°C (adjustable by calibration)

K

± 0,35 (at 100 °C)

Temperature setting

Knob

Temperature setting resolution

K

0,1

Temperature display

LED

Temperature display resolution

K

0,1

Classification according to DIN12876-1

Class III (FL) suitable for flammable and non-flammable fluids

Safety circuit (adjustable)

°C

0 ... 260

Safety temperature display

LED

Heating capacity

W

2500 (230 VAC)/1250 (115 VAC)

Pump speed (adjustable)

rpm

1000 ... 4000

Max. pump pressure/suction

bar

0,5/0,3

Max. flow rate (at 0 bar)

l/min

20

Bath volume

I

-/-

5 - 7

8 - 11

Sub-level protection

Yes

Interface

USB, RS 232

Permitted on-time

%

100

Protection class according to EN 60529

IP 21

Protection class

I

Excess voltage category

II

Contamination level

2

Permitted ambient temperature

°C

+5 ... +40

Permitted ambient humidity

%

80

Dimension (W x D x H)

mm

285 x 291 x 313

275 x 500 x 406

275 x 510 x 456

Weight

kg

8,5

17,0

18,0

Operation at a terrestrial altitude

m

max. 2000

Subject to technical changes!

39

Warranty

In accordance with

IKA

®

warranty conditions, the warranty

period is 24 months. For claims under the warranty please

contact your local dealer. You may also send the machine

direct to our factory, enclosing the delivery invoice and giv-

ing reasons for the claim. You will be liable for freight costs.

The warranty does not cover worn out parts, nor does

it apply to faults resulting from improper use, insufficient

care or maintenance not carried out in accordance with

the instructions in this operating manual.

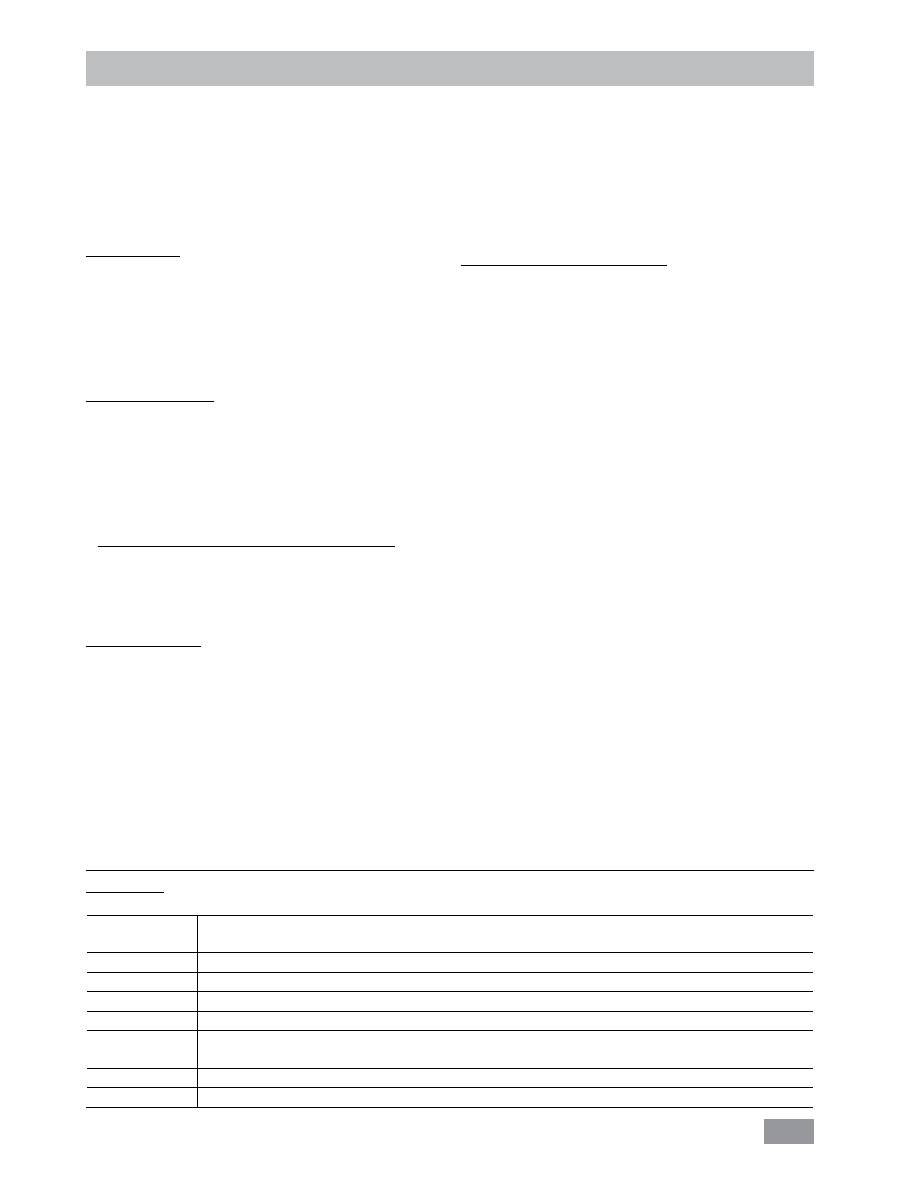

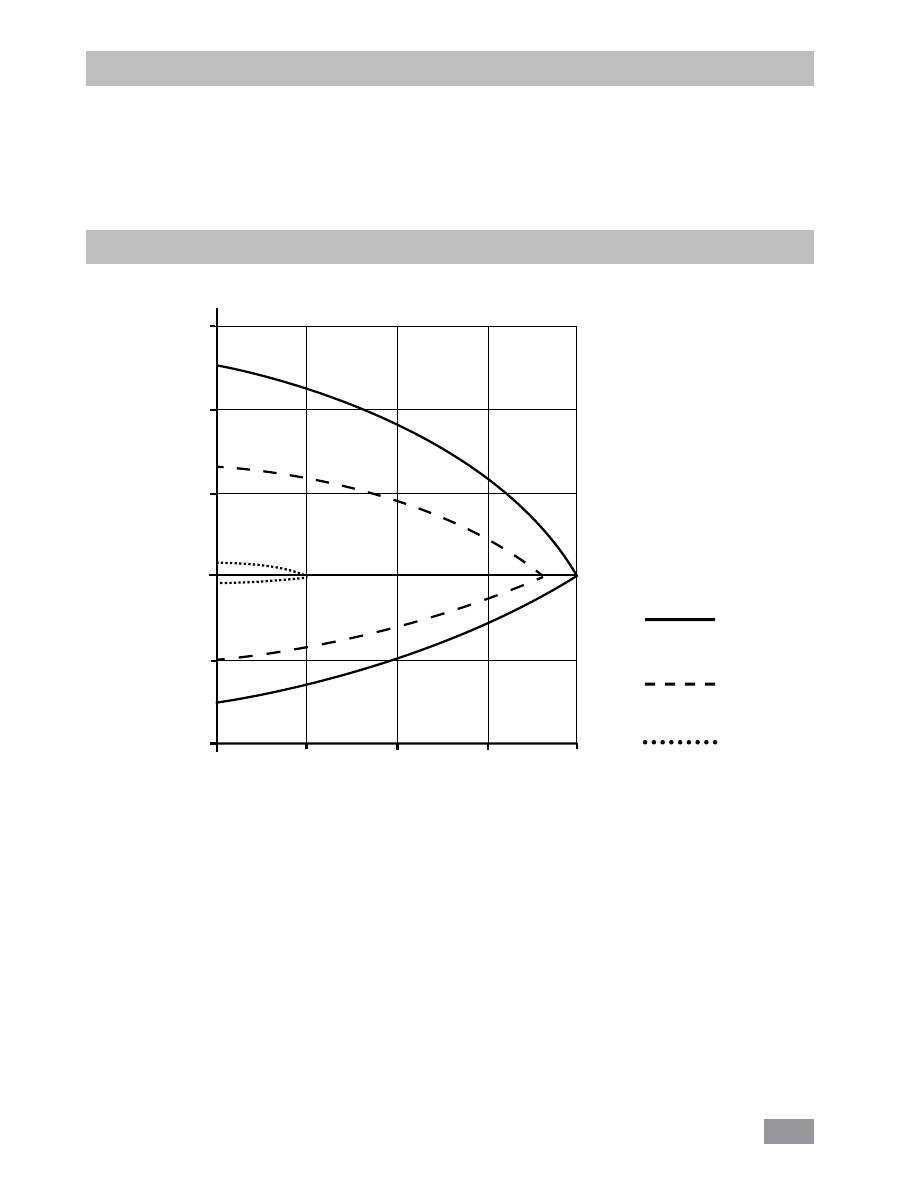

0,6 0,4 0,2 0,0 -0,2 -0,4 0 5 10 15 20 Q [l/min] P [bar]

Pump performance curve

4000 rpm

3000 rpm

1000 rpm

Fig. 18

Pump performance curve measured with water

40

Sommaire

FR

Langue d‘origine: allemand

Page

Déclaration de conformité CE .................................................................................................................41

Explication des symboles ........................................................................................................................41

Consignes de sécurité ..............................................................................................................................42

Consignes générales ...................................................................................................................................... 42

Liquides ......................................................................................................................................................... 43

Utilisation conforme ................................................................................................................................44

Utilisation ..................................................................................................................................................... 44

Zone d’utilisation (uniquement en intérieur) ................................................................................................... 44

Déballage ................................................................................................................................................44

Déballage ...................................................................................................................................................... 44

Contenu de la livraison ................................................................................................................................... 44

Préparatifs ..............................................................................................................................................45

Installatio ....................................................................................................................................................... 45

Raccordement des tuyauteries/flexibles ........................................................................................................... 45

Remplissage et vidage .................................................................................................................................... 45

Liquides ......................................................................................................................................................... 46

Serpentin de refroidissement .......................................................................................................................... 46

Tableau de commande et affichage .........................................................................................................47

Mise en service ........................................................................................................................................48

Réglage de la température de sécurité ....................................................................................................48

Menu «Réglages» ....................................................................................................................................49

Structure des menus ...................................................................................................................................... 49

Informations générales sur le réglage des options de menu ........................................................................... 49

Mode de fonctionnement (MODE) ................................................................................................................. 49

Température maximale (HI T) .......................................................................................................................... 49

Température minimale (LO T) .......................................................................................................................... 49

Vitesse de rotation maximale (HI R) ................................................................................................................ 50

Vitesse de rotation minimale (LO R) ................................................................................................................ 50

Type de liquide (FLUI) ..................................................................................................................................... 50

Type de régulation de température (AUTO) ..................................................................................................... 50

Régulation de température externe et interne (ET) ......................................................................................... 51

Son pour l’alarme et les touches (BEEP) .......................................................................................................... 51

Étalonnage et alignement (CALI) .................................................................................................................... 51

Interfaces et sorties .................................................................................................................................52

Entretien et nettoyage ............................................................................................................................54

Codes d’erreur .........................................................................................................................................55

Accessoires ..............................................................................................................................................56

Caractéristiques techniques .....................................................................................................................57

Garantie ..................................................................................................................................................58

Courbe caractéristique de la pompe ........................................................................................................58