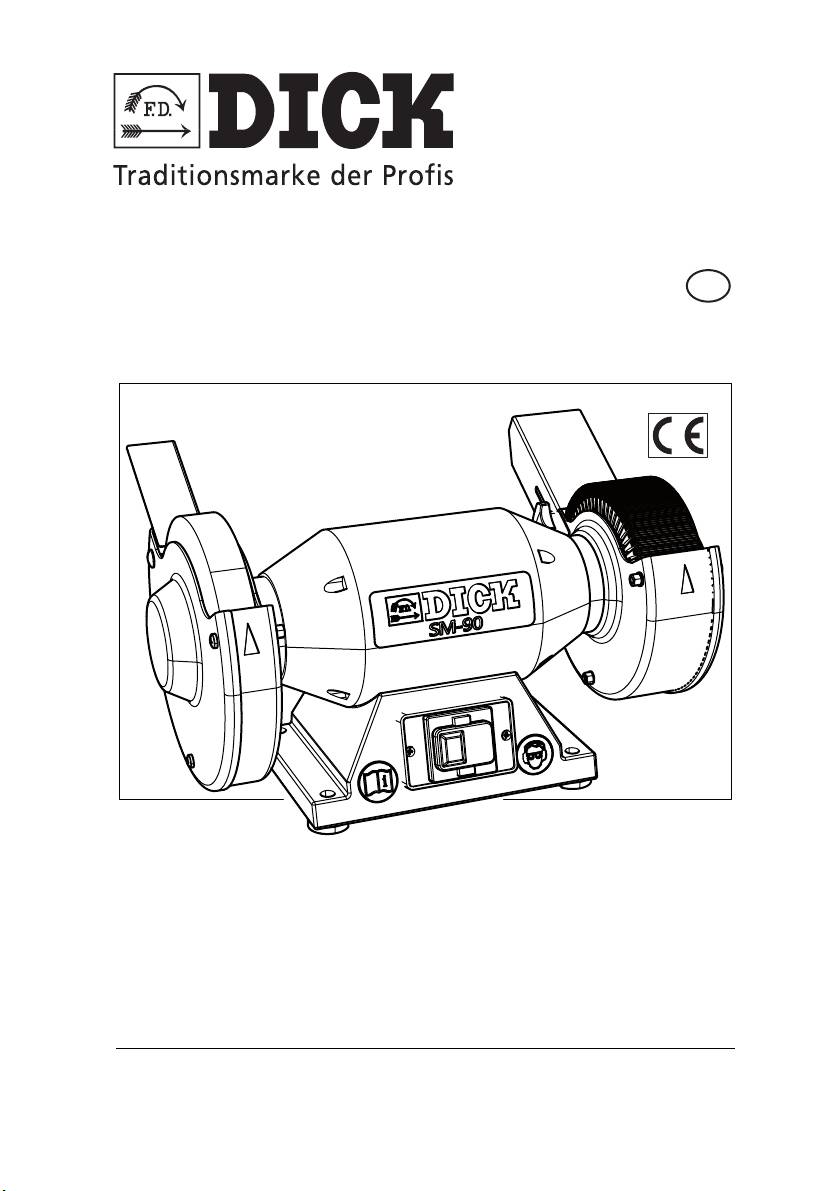

Dickson Industrial SM-90 230V: SM-90

SM-90: Dickson Industrial SM-90 230V

Operating instructions (Translation)

GB

SM-90

1~230 V - 50 Hz

Lamellar grinding machine

Art. No. 9 8080 000

Friedr. Dick GmbH & Co. KG · Postfach 1173 · 73777 Deizisau · GERMANY ·

Nr. 9 8080 3774 Vers. 1 / 10-2012

Tel.: +49 (0)7153-817-0 · Fax: +49 (0)7153-817-218/-219 · Web: www.dick.de · Mail: mail@dick.de

Manufacturer and customer service address

Friedr. Dick GmbH & Co. KG

Postfach 1173

73777 Deizisau

GERMANY

Copyright

© 2012 Friedr. Dick GmbH & Co. KG.

These operating instructions are protected by copyright; all rights

are reserved.

These operating instructions may not be reproduced or copied, either in full or

in part, without the prior consent of Friedr. Dick GmbH & Co. KG. Infringements

are subject to compensation claims and can result in criminal prosecution.

1 User Information ............................................................................ 4

1.1 General ..................................................................................................4

1.2 Symbols and conventions ......................................................................4

Manuals and Instructions .....................................................................4

Lists......................................................................................................5

1.3 Symbols .................................................................................................5

2 Scope of Supply............................................................................. 6

2.1 Package contents ..................................................................................6

2.2 Unpack lamellar grinding machine.........................................................6

3 Product Liability............................................................................. 7

3 Environmental protection ............................................................. 7

5 Safety .............................................................................................. 8

5.1 Meaning of the warnings........................................................................8

5.2 Intended use ..........................................................................................8

5.3 General safety instructions ....................................................................9

5.4 Information signs on the lamellar grinding machine.............................11

5.5 Covers..................................................................................................12

6 Structure and Function ............................................................... 13

6.1 Technical data......................................................................................13

6.2 Structure ..............................................................................................14

6.3 Function ...............................................................................................15

6.4 Covers..................................................................................................15

7 Putting into operation.................................................................. 16

7.1 Positioning the lamellar grinding machine ...........................................16

7.2 Installing the lamellar grinding machine...............................................17

7.3 Adjusting the lamellar grinding machine ..............................................17

Adjusting the deflector plates.............................................................18

Controls on the lamellar grinding machine.........................................19

7.4 Switching on the lamellar grinding machine.........................................19

7.5 Switching off the lamellar grinding machine.........................................21

8 Machining Workpieces................................................................ 23

8.1 Grinding workpieces ............................................................................23

8.2 Polishing workpieces ...........................................................................26

9 Servicing and Maintenance......................................................... 27

9.1 Cleaning the lamellar grinding machine...............................................27

9.2 Changing the lamellar grinding wheel..................................................27

9.3 Changing the polishing wheel ..............................................................29

10 Spare Parts................................................................................... 30

10.1 Spare parts drawing.............................................................................30

10.2 Ordering spare parts ............................................................................31

11 EC Declaration of Conformity..................................................... 32

SM-90 lamellar grinding machine 3

User Information

1

1. User Information

1.1 General

These operating instructions are part of the SM-90 lamellar grin-

ding machine with the serial number given on the type plate (the

type plate is located on the back of the lamellar grinding machine).

The operating instructions must be kept close at hand at all times.

It contains important information and instructions for safe, proper

and economic use of the lamellar grinding machine. It must have

been read and understood by each person before this person can

be entrusted with the following work using the lamellar grinding

machine:

• putting into operation,

• operating,

• servicing.

The operating instructions must be followed during all work on and

with the lamellar grinding machine. Following the information and

instructions in the manual helps to prevent hazards, to reduce

repair costs and to increase the reliability and life of the lamellar

grinding machine.

The technical information and instructions for use in these opera-

ting instructions are up-to-date and correct on delivery of the lamel-

lar grinding machine. Friedr. Dick GmbH & Co. KG reserves the

right to further develop the design and to make changes without

notice.

All directional information is given from the view of the user.

1.2 Symbols and conventions

Manuals and Instructions

Sequences of actions, which must be carried out in the given

order, are given as a numbered list. Example:

1 Instruction step 1.

2 Instruction step 2.

4

SM-90 lamellar grinding machine

User Information

1

Lists

Lists without a particular order that has to be followed are

shown as a list with bullet points or indent markings.

Example:

• Property A

- Detail 1

- Detail 2

• Property B

1.3 Symbols

Important or particularly useful information is highlighted by way of

symbols so that it is readily recognised.

WARNING

This symbol denotes a warning, which must always be noted and

followed.

• For more information on the meaning of the warnings, refer to

the Safety chapter.

MANDATORY

This symbol indicates instructions, which must be complied with

for safety reasons.

NOTE, TIP

This symbol denotes general information, which contains user

tips and useful information.

SM-90 lamellar grinding machine 5

Scope of Supply

2

2. Scope of Supply

2.1 Package contents

• Lamellar grinding machine

• Operating instructions

• Set of tools

• Polishing paste

2.2 Unpack lamellar grinding machine

Unpack the lamellar grinding machine immediately after purchase

and check whether it has any defects or transport damage. Also

check the package contents for complete scope of supply.

Report any defects immediately. Complaints made at a later date

can no longer be recognised.

Keep the invoice for the entire warranty period as proof of pur-

chase.

In case of complaints, write to Friedr. Dick GmbH & Co. KG,

enclose the original invoice and a precise description of the

defect(s).

Before returning the product, wait for the manufacturer’s reply in

order to initiate the necessary steps.

Friedr. Dick GmbH & Co. KG does not pay any transport costs for

returns that have not explicitly approved.

Keep the original box for any necessary returns, in order to prevent

transport damage.

DAMAGE TO THE LAMELLAR GRINDING MACHINE DUE TO

CONNECTION DATA NOT IN LINE WITH THE SPECIFIED

DATA

• Before starting up the lamellar grinding machine, compare

the lamellar grinding machine’s electrical data (See “Techni-

cal data” on page 13) with the connection data on site.

6

SM-90 lamellar grinding machine

Product Liability

3

3. Product Liability

DICK lamellar grinding machines are sold with a 12 month guaran-

tee for the owner, starting from the day of delivery (verification by

means of invoice).

All abrasives and other wearing parts are excluded from the guar-

antee.

Changes to the lamellar grinding machine require the manufac-

turer's prior written approval.

Friedr. Dick GmbH & Co. KG does not accept any liability whatso-

ever for defects or damage caused by incorrect assembly or

improper handling.

For further details of the guarantee, please refer to our General

Terms and Conditions of Sale, Delivery and Payment.

4. Environmental protection

Used machines, replacement parts and packaging are made of

recyclable materials. The owner is obliged to dispose of them

properly and in an environmentally friendly way, in accordance

with the legal regulations.

SM-90 lamellar grinding machine 7

Safety

5

5. Safety

5.1 Meaning of the warnings

In these operating instructions, a differentiation is made between

warnings depending on the hazard:

DANGER

Imminent risk to life and the health of people.

• Causes serious injuries or death.

WARNING

Possibly imminent risk to the life and health of people.

• Could cause serious injuries or death.

CAUTION

Possibly dangerous situation

• Could cause minor injuries.

5.2 Intended use

The SM-90 lamellar grinding machine is solely designed for com-

mercial use.

The SM-90 lamellar grinding machine can be used for hand-gui-

ded dry grinding (sharpening) and polishing of cleaned knives and

cutting tools.

Any other or additional use is deemed to be not as intended and

therefore misuse.

The grinding of materials which produce harmful or readily igni-

table dusts is deemed to be misuse.

8

SM-90 lamellar grinding machine

Safety

5

These include, for example:

• Aluminium

• Magnesium

The lamellar grinding machine may not be switched on or operated

in potentially explosive atmospheres and is solely designed for use

in dry rooms at temperatures between +3 and +30 °C.

Only original spare parts and accessories of Friedr. Dick GmbH &

Co. KG may be used.

The owner is responsible for any damage caused by misuse.

5.3 General safety instructions

WARNING

Risk of injuries due to incorrect handling

Incorrect handling of the lamellar grinding machine can cause

substantial injuries.

• The lamellar grinding machine may only be used by people

who have read and understood the operating instructions.

• The lamellar grinding machine may only be operated by peo-

ple who are familiar with the starting up, operation, and servi-

cing of machines and the relevant accident prevention

regulations, who are able to recognise the hazards that occur

during the grinder's use and who work reliably.

• The lamellar grinding machine may not be operated outside

the given power ranges (see “Technical data” on page 13).

• Operate the lamellar grinding machine only for its approved

uses (see “Intended use” on page 8).

SM-90 lamellar grinding machine 9

Safety

5

WARNING

Risk of fire in the event of unsuitable environmental influ-

ences

Moisture (humidity) and water can cause a short circuit. Flying

sparks can cause flammable liquids and gases to ignite.

• Do not expose the lamellar grinding machine to rain or salt

water.

• Do not use the lamellar grinding machine in a damp or wet

environment.

• Ensure good lighting.

• Do not use the lamellar grinding machine near flammable

liquids or gases.

Before each transport, switch off the lamellar grinding machine

and remove the mains plug from the socket.

10

SM-90 lamellar grinding machine

Safety

5

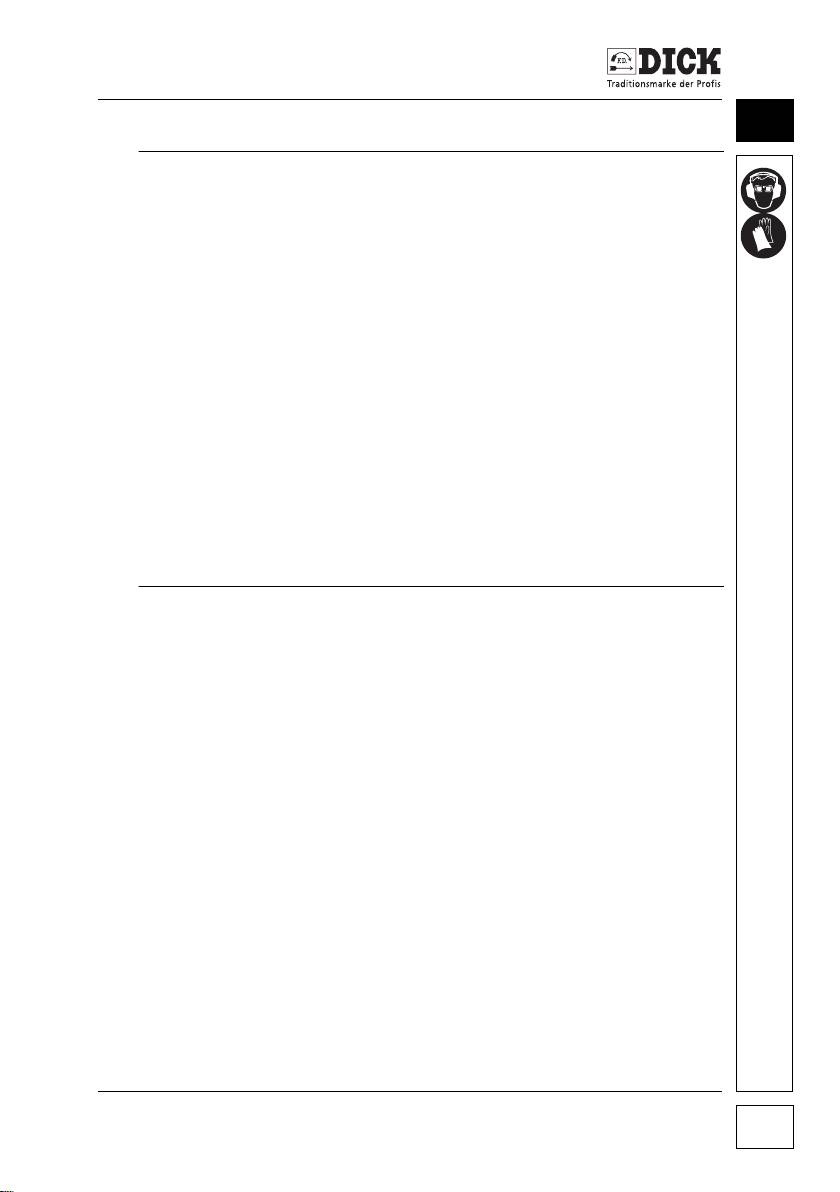

5.4 Information signs on the lamellar grinding

machine

5

1

4

2

3

Figure 5.1 – Information on the lamellar grinding machine

[1] Wear hearing protection and safety glasses or goggles when

working with the lamellar grinding machine

[2] Caution! Electric shock!

[3] Type plate

[4] Disconnect the mains plug from the socket

[5] Read the operating instructions before starting up

SM-90 lamellar grinding machine 11

Safety

5

6

Figure 5.2 – direction of rotation of the lamellar grinding machine

[6] Rotational direction information on the polishing wheel and

lamellar grinding wheel

5.5 Covers

WARNING

Risk of injuries due to missing covers

The lamellar grinding machine may not be started up until all

covers and guards on the polishing wheel and lamellar grinding

wheel (see Figure 6.2 – Structure and Function) are fully functio-

nal.

12

SM-90 lamellar grinding machine

Structure and Function

6

6. Structure and Function

6.1 Technical data

Motor and electrics

Power: 0.37 kW

Voltage: 1~230 V

Current intensity: 1.7 A

Frequency: 50 Hz

Degree of protection: IP 44

Type of operation: S2 - 30 min

Connection: 1.8 m cable H05VVF3G0.75

Euro earthing pin plug

Nominal speed: 1450 rpm

Lamellar grinding wheel

Dimensions: ø200 x 50 x ø16 mm

Cutting speed: V

= 15.5 m/s

c

with lamellar grinding wheel diameter

200 mm

Polishing wheel

Dimensions: ø200 x 25 x ø16 mm

Cutting speed: V

= 15.5 m/s

c

with polishing wheel diameter 200 mm

Machine dimensions / weights

Depth: 303 mm

Width: 432 mm

Height: 245 mm

Weight: 14.9 kg

Emissions sound pressure level

Sound emissions to EN 11201 during the grinding of boning

knives.

Emissions sound pressure level L

76 dB (A)

pA:

Uncertainty KpA: 3 dB (A)

Emissions sound pressure level L

89 dB (A)

WA:

Uncertainty KpA: 3 dB (A)

SM-90 lamellar grinding machine 13

Structure and Function

6

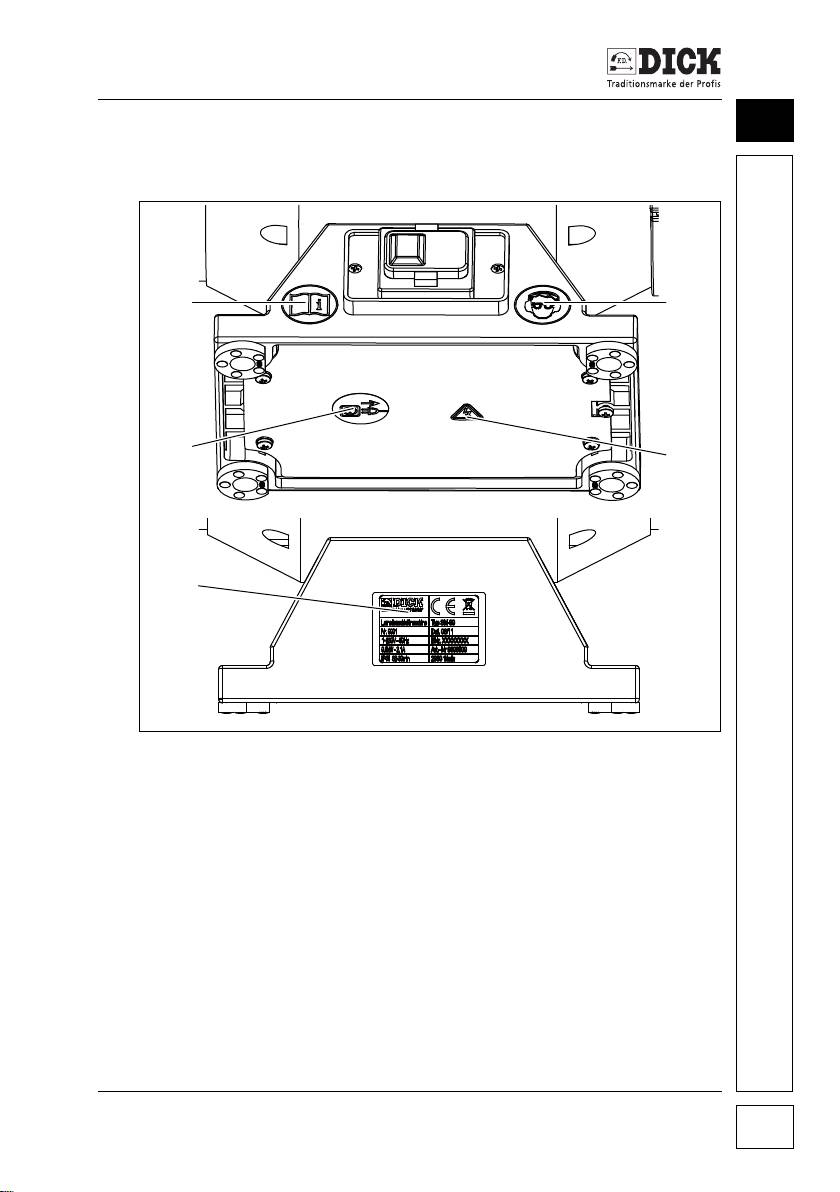

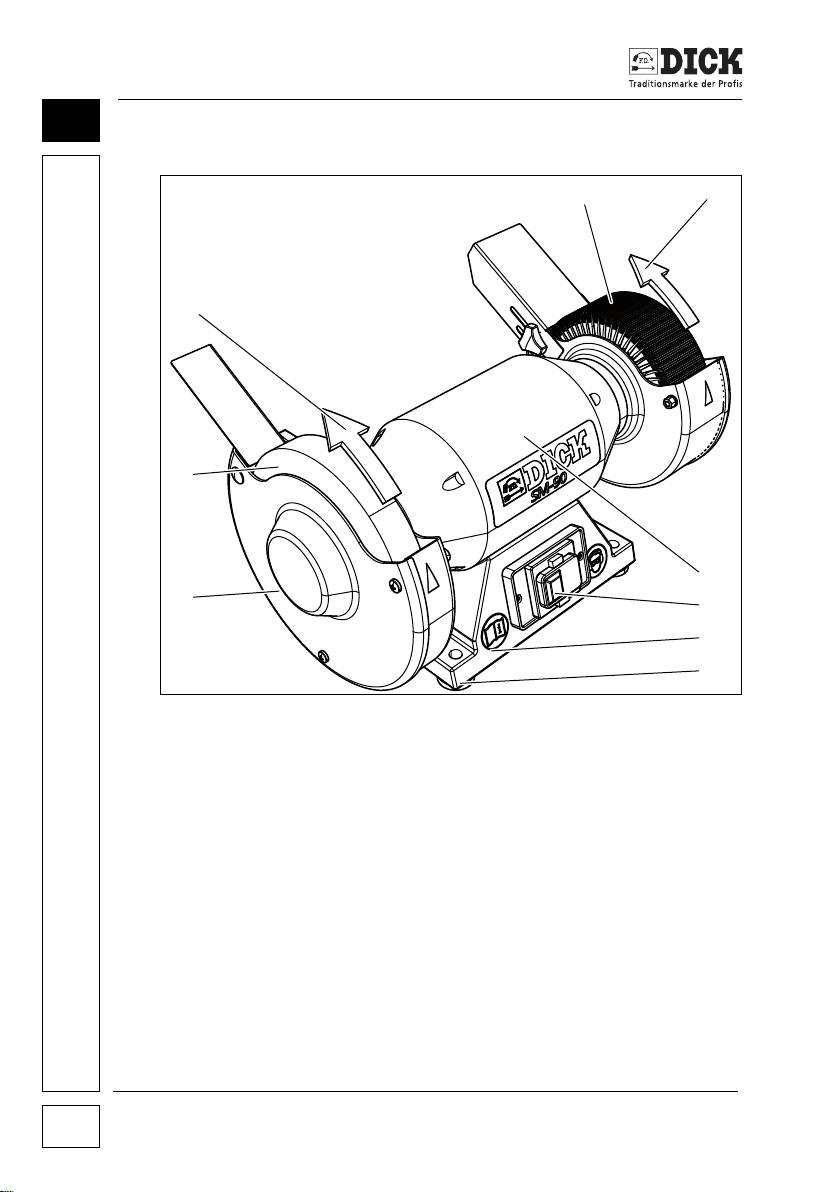

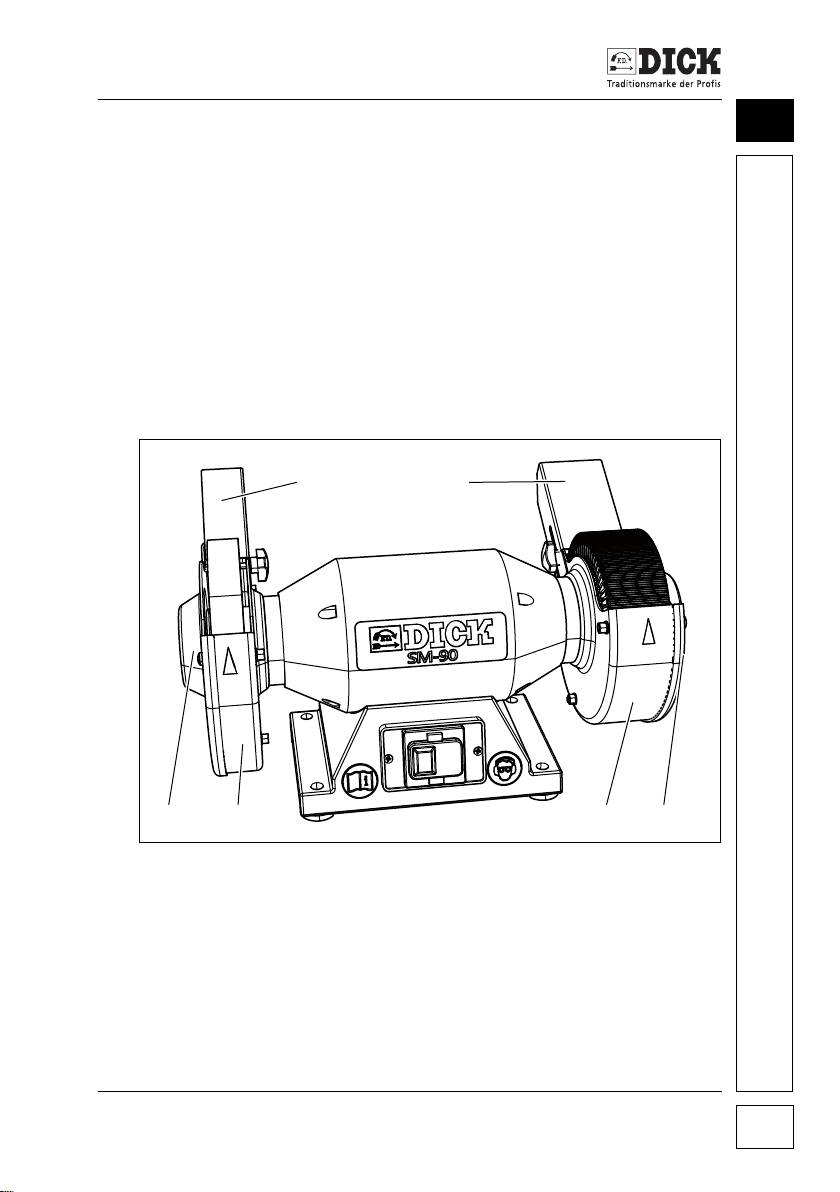

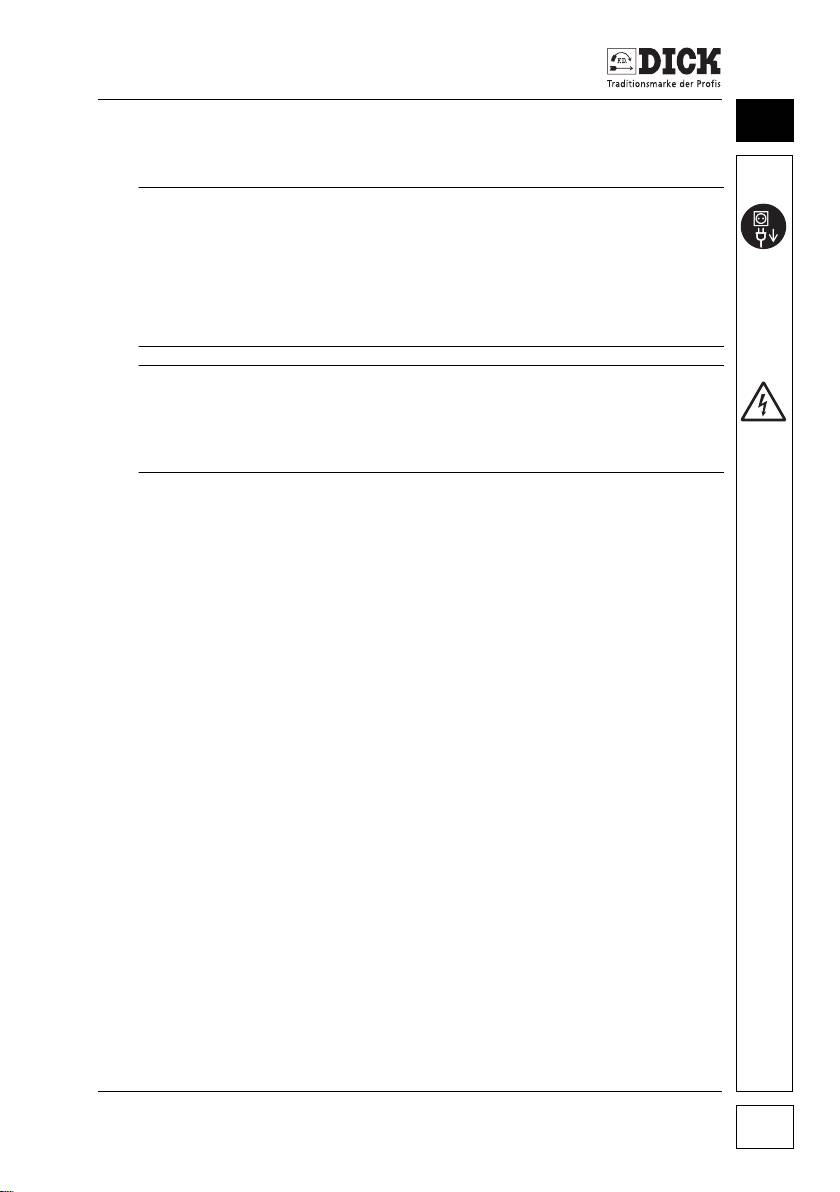

6.2 Structure

1

2

9

8

3

7

4

5

6

Figure 6.1 – Structure of the lamellar grinding machine

[1] Lamellar grinding wheel

[2] Direction of rotation of the lamellar grinding wheel

[3] Drive motor

[4] Switch

[5] Base

[6] Machine bases

[7] Polishing station

[8] Polishing wheel

[9] Direction of rotation of the polishing wheel

14

SM-90 lamellar grinding machine

Structure and Function

6

6.3 Function

The lamellar grinding machine consists of two functional groups: A

lamellar grinding wheel [1] in the grinding station and a polishing

station [7] with the polishing wheel [8]. The polishing station is

mounted on the left of the drive motor [3] and the grinding station

is mounted on its right. The drive motor sits on a base [5]. The

switch [4] and the four machine bases [6] are fixed to the base.

The specified direction of rotation for the polishing wheel [9] and

the lamellar grinding wheel [2] is marked on the lamellar grinding

machine.

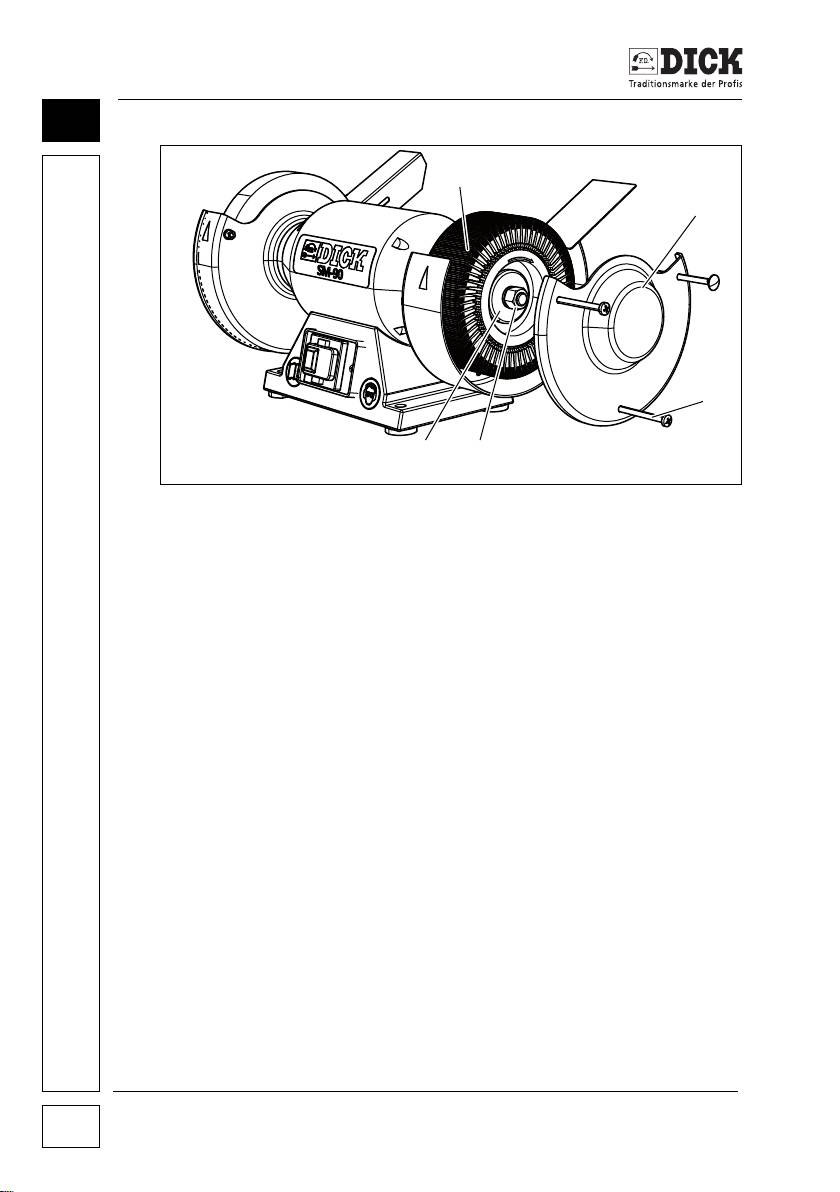

6.4 Covers

12

3456

Figure 6.2 – Covering danger zones

[1] Polishing wheel deflection plate

[2] Lamellar grinding wheel deflection plate

[3] Lamellar grinding wheel cover

[4] Lamellar grinding wheel guard

[5] Polishing wheel guard

[6] Polishing wheel cover

SM-90 lamellar grinding machine 15

Putting into operation

7

7. Putting into operation

7.1 Positioning the lamellar grinding machine

WARNING

Risk of injuries in the event of slipping, falling or tilting

lamellar grinding machine

• Place the lamellar grinding machine on a stable table or other

stand or substructure, which has sufficient stability to carry

the weight of the lamellar grinding machine.

• The stand must not be mobile or fitted with wheels or castors.

• Place the lamellar grinding machine on a flat, slip-proof sur-

face so that the lamellar grinding machine does not slip, tilt or

otherwise move when used.

WARNING

Risk of injuries in case of a posture in which the user can-

not maintain their balance

• Adjust the height of the base unit to the height of the operator

so that they work in an upright, stable position, in which they

are able to maintain their balance.

16

SM-90 lamellar grinding machine

Putting into operation

7

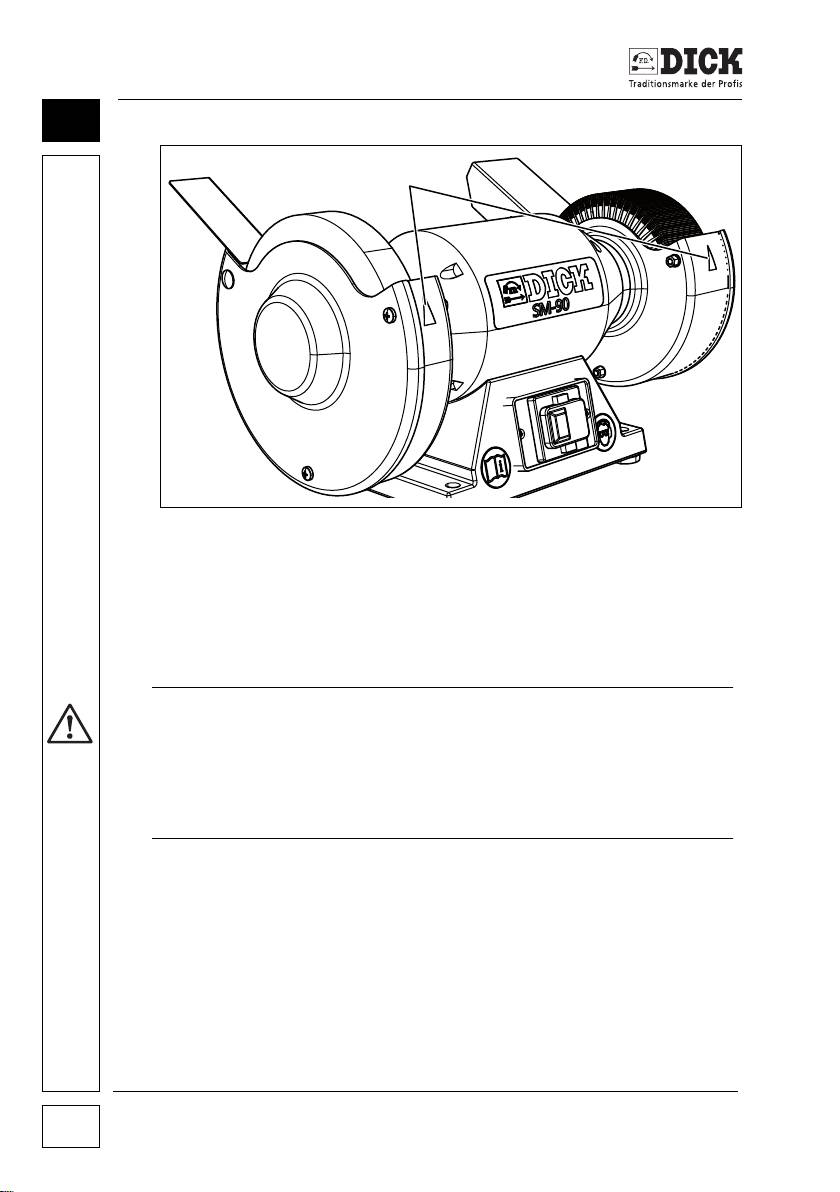

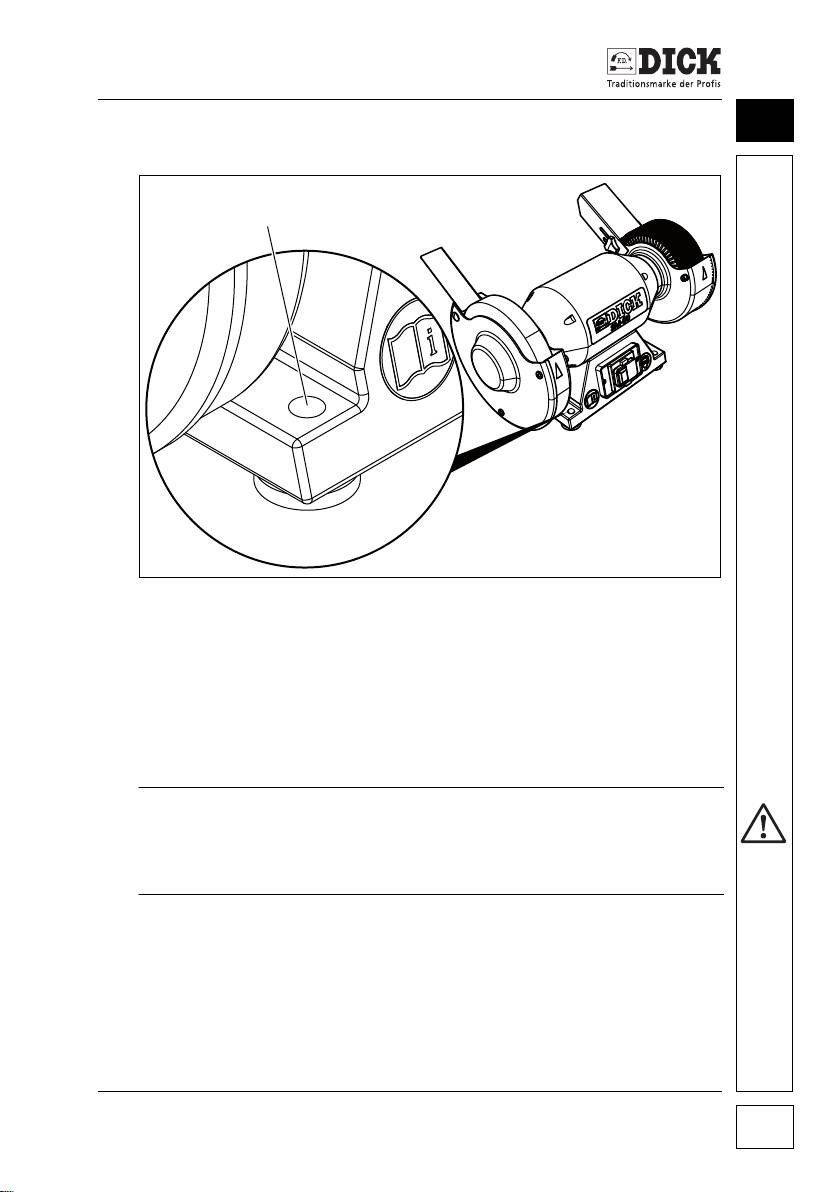

7.2 Installing the lamellar grinding machine

1

Figure 7.1 – Installation

[1] Mounting holes

The lamellar grinding machine is fixed onto the surface using the

mounting holes [1].

7.3 Adjusting the lamellar grinding machine

IMPORTANT

Risk of injuries due to rotating machine parts

• Remove the plug from the socket before carrying out any

adjustment work.

SM-90 lamellar grinding machine 17

Putting into operation

7

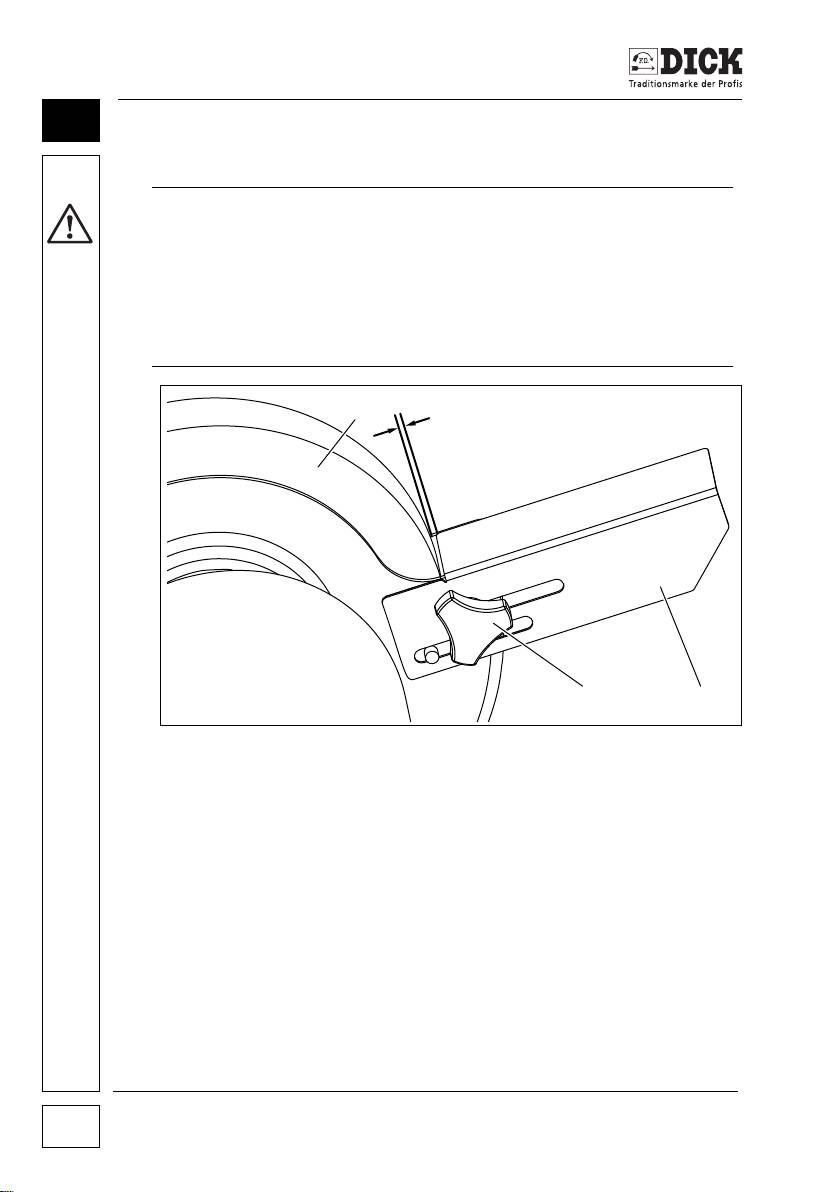

Adjusting the deflector plates

WARNING

Risk of injuries due to rotating machine parts

• The distance between the deflection plate and polishing

wheel or the deflection plate and lamellar grinding wheel

(adjusting the deflection plate) must be checked each time

before starting work using the lamellar grinding machine, and

if necessary readjusted.

1

2

34

Figure 7.2 – Adjusting the deflection plates

[1] Polishing wheel

[2] Distance (2 mm)

[3] Deflection plate

[4] Star knob

Adjust the distance [2] between the deflection plate [3] and the

polishing wheel [1] to 2 mm.

• Adjust the distance using the star knob [4].

18

SM-90 lamellar grinding machine

Putting into operation

7

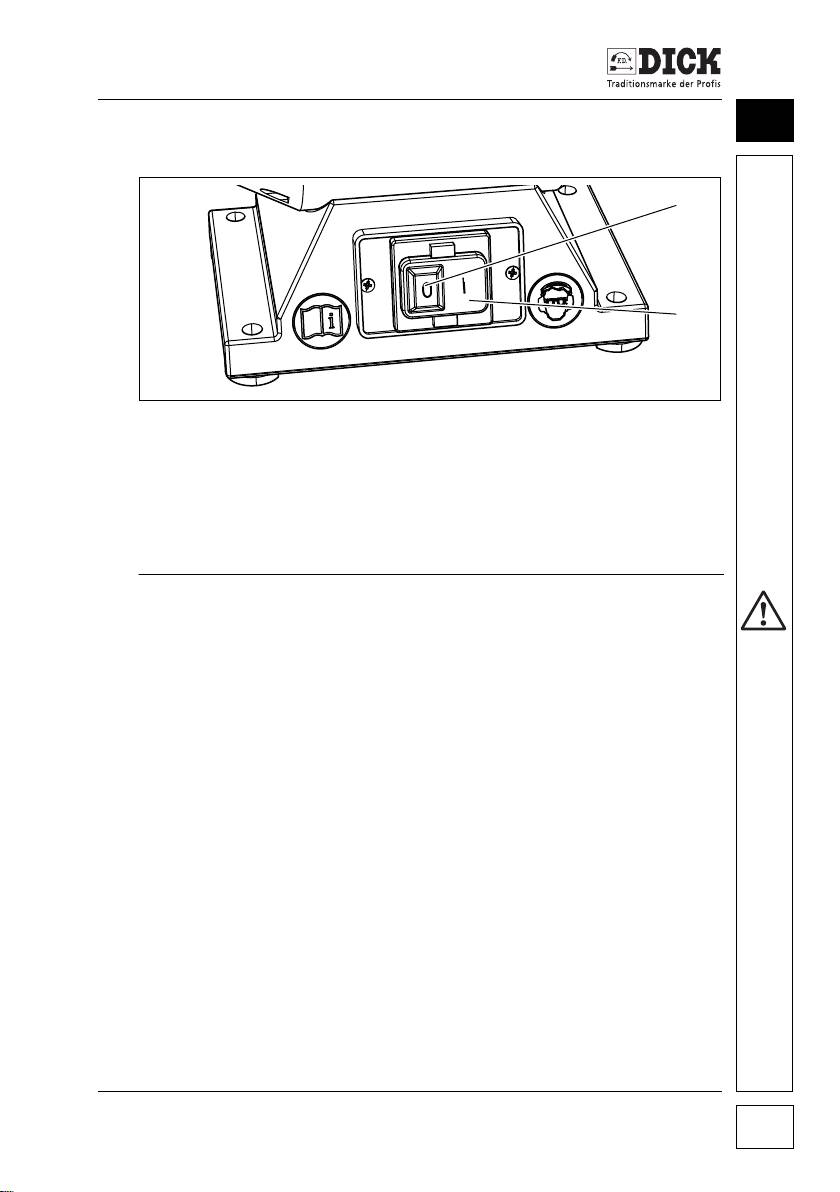

Controls on the lamellar grinding machine

1

2

Figure 7.3 – Switches

[1] Switch for switching off (red, 0)

[2] Switch for switching on (green, I)

7.4 Switching on the lamellar grinding machine

WARNING

Risk of injury due to damaged or incorrectly mounted

machine parts

Using the lamellar grinding machine with damaged electric parts

or power cables can cause injuries due to electric shocks or mal-

functions. Damaged fins can be partly spun off the machine.

• Missing or damaged covers expose rotating parts and can

cause injuries due to crushing and drawing in. Check the

lamellar grinding machine for damage before each use, in

particular:

- the lamellar grinding wheel,

- the polishing wheel,

- the power cable,

SM-90 lamellar grinding machine 19

Putting into operation

7

- correct assembly and covering function of all covers and

the housing,

- the function of the switches.

• Replace damaged parts before using the lamellar grinding

machine again.

CAUTION

Risk of injuries due to poor health of the operator

Lack of concentration, over-tiredness, illness, drunkenness or

leg or arm disabilities as well as mental disabilities cause a high

risk of injuries.

• People who work at the lamellar grinding machine must be

healthy and capable of concentrating.

• Before starting work at or with the lamellar grinding machine,

ensure that you are in a stable position in which you can

maintain your balance without any effort.

• When grinding and polishing, do not look away from the

lamellar grinding machine and workpiece.

CAUTION

Risk of injuries on touching the lamellar grinding machine

Touching the lamellar grinding wheel or polishing wheel while the

lamellar grinding machine is switched on causes injuries.

• Do not touch any abrasives while the lamellar grinding

machine is switched on.

• Do not use any objects to brake rotating abrasives.

• The switched on lamellar grinding machine must be inacces-

sible to persons not working at the lamellar grinding machine,

especially to children.

• Before leaving the work area, switch off the lamellar grinding

machine and disconnect the mains plug from the socket.

20

SM-90 lamellar grinding machine

Putting into operation

7

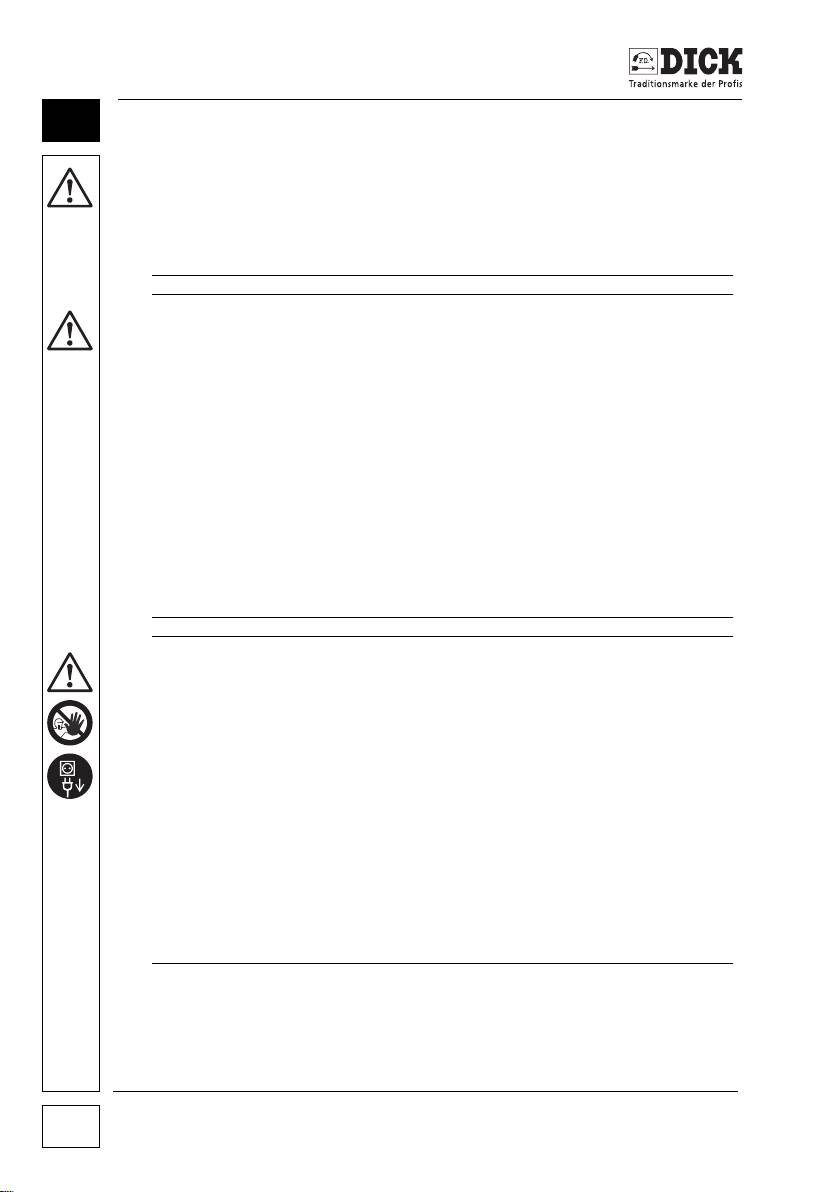

WEAR SUITABLE PROTECTIVE CLOTHING

Rotating machine parts can catch unsuitable clothing or long hair.

Abrasive particles spun off the machine or loud machine noises

can damage eyes and ears.

Sharp and hot workpieces can cause injuries to hands.

Rotating abrasives can pull off pieces of clothing.

• Ensure good lighting is available,

• wear tight-fitting clothing,

• do not wear jewellery,

• wear a hair net on long hair,

• wear safety glasses or goggles,

• wear hearing protection,

• wear suitable protective gloves,

• do not touch rotating machine parts with parts of the body

covered with fabric.

Switch on the lamellar grinding machine as follows:

1 Insert the plug into the socket.

2 Press the green button (switch) at the switch.

3 Check the direction of rotation when starting up the lamellar

grinding machine.

- The direction of rotation is given by arrows on the covers.

7.5 Switching off the lamellar grinding machine

1 Press the red switch (switch, Item [1]).

2 Wait until the lamellar grinding wheel and the polishing

wheel stop.

SM-90 lamellar grinding machine 21

Putting into operation

7

DANGER

Risk of electric shock

If the plug is removed from the socket by pulling the power cable,

the connection between the plug and cable can be damaged and

is therefore a substantial source of danger.

• When disconnecting the power connection, hold onto the

plug and pull it out of the socket.

3 Disconnect the mains plug from the socket.

4 Clean the lamellar grinding machine.

WARNING

Risk of injuries after thoughtless switching on of the lamel-

lar grinding machine

If the lamellar grinding machine is left unattended after grinding

work, there is a risk of the lamellar grinding machine being swit-

ched on by unauthorised or thoughtless persons.

• After carrying out grinding work, never leave the lamellar

grinding machine unsupervised unless the mains plug has

been disconnected.

• Store the lamellar grinding machine in a safe place, to which

unauthorised persons do not have access.

22

SM-90 lamellar grinding machine

Machining Workpieces

8

8. Machining Workpieces

8.1 Grinding workpieces

NOTE

Dirty knives can irreparably damage the lamellar grinding

wheel and polishing wheel. The surfaces can heat with long-

term use.

• Only machine clean knives.

• Switch off the lamellar grinding machine after 30 minutes at

the latest.

1

3

2

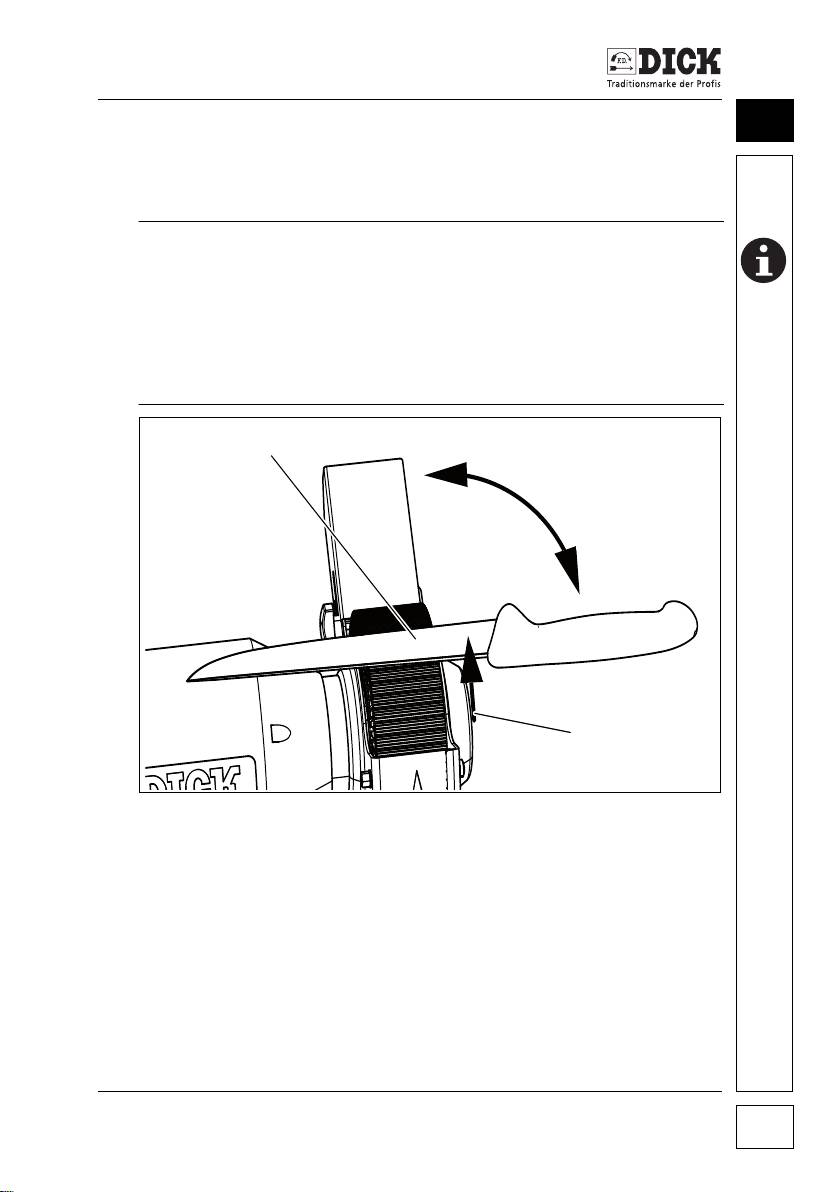

Figure 8.1 – Grinding knives

[1] Knife edge

[2] Direction of rotation of the lamellar grinding wheel

[3] Right-angled alignment of the blade with the lamellar grinding

wheel

SM-90 lamellar grinding machine 23

Machining Workpieces

8

4

5

Figure 8.2 – Grinding (sharpening) knives

[4] Knife blade

[5] Positioning angle for the knife blade (10°)

WARNING

Risk of injuries due to pulling in (entanglement) and cutting

When the workpieces are positioned against the direction of rota-

tion, the workpieces can be caught and spun away from the

machine.

• Never guide the workpieces at the lamellar grinding wheel or

polishing wheel against their direction of rotation.

1 Position the knife at the lamellar grinding machine so that

the knife edge [1] points in the direction of rotation of the

lamellar grinding wheel [2] or the polishing wheel.

2 Align the workpieces horizontally so that they are positioned

roughly perpendicular [3] to the lamellar grinding wheel.

3 Position the knife blade [4] on the lamellar grinding wheel at

an angle of approx. 10 degrees [5].

4 When grinding, grind the sides of the workpiece alternately,

until a burr has formed over the entire area.

24

SM-90 lamellar grinding machine

Machining Workpieces

8

NOTE

Workpieces heat during grinding

An over-heated blade can anneal (loss of hardness) and stress

cracks can form in it.

• After several grinding passes, cool the workpiece in a water

bath.

NOTE

If the blade has become thicker as a result of frequent grinding,

the blade thickness can be reduced again by grinding the flat

sides.

SM-90 lamellar grinding machine 25

Machining Workpieces

8

8.2 Polishing workpieces

2

1

Figure 8.3 – Polishing knives

[1] Positioning angle slanted relative to the running direction

(approx. 30°

-

60°)

[2] Positioning angle relative to the polishing wheel (approx. 20°)

1 Hold the polishing paste against the polishing wheel while it

is running.

2 Position the knife slanted relative to the running direction.

3 Position the knife at the polishing wheel at a more obtuse

angle than for grinding.

4 Polish both sides of the blade alternately.

5 Polish the knife until the burr has been completely removed

and the surface has reached the required polish.

26

SM-90 lamellar grinding machine

Servicing and Maintenance

9

9. Servicing and Maintenance

WARNING

Risk of injuries due to unauthorised or thoughtless swit-

ching on or wrong spare parts

• Always disconnect the mains plug before carrying out any

maintenance or repair work on the lamellar grinding machine.

• Only use original spare parts of Friedr. Dick GmbH & Co. KG.

WARNING

Risk of injuries due to improper repair work

• Any repair work on electric components may only be carried

out by qualified electricians.

9.1 Cleaning the lamellar grinding machine

The lamellar grinding machine must be cleaned after each work

session.

1 Remove covers (Figure 6.2 – Structure and Function chap-

ter).

2 Remove residual abraded material from the machine,

e.g. using a brush.

3 Re-attach covers and screw tight.

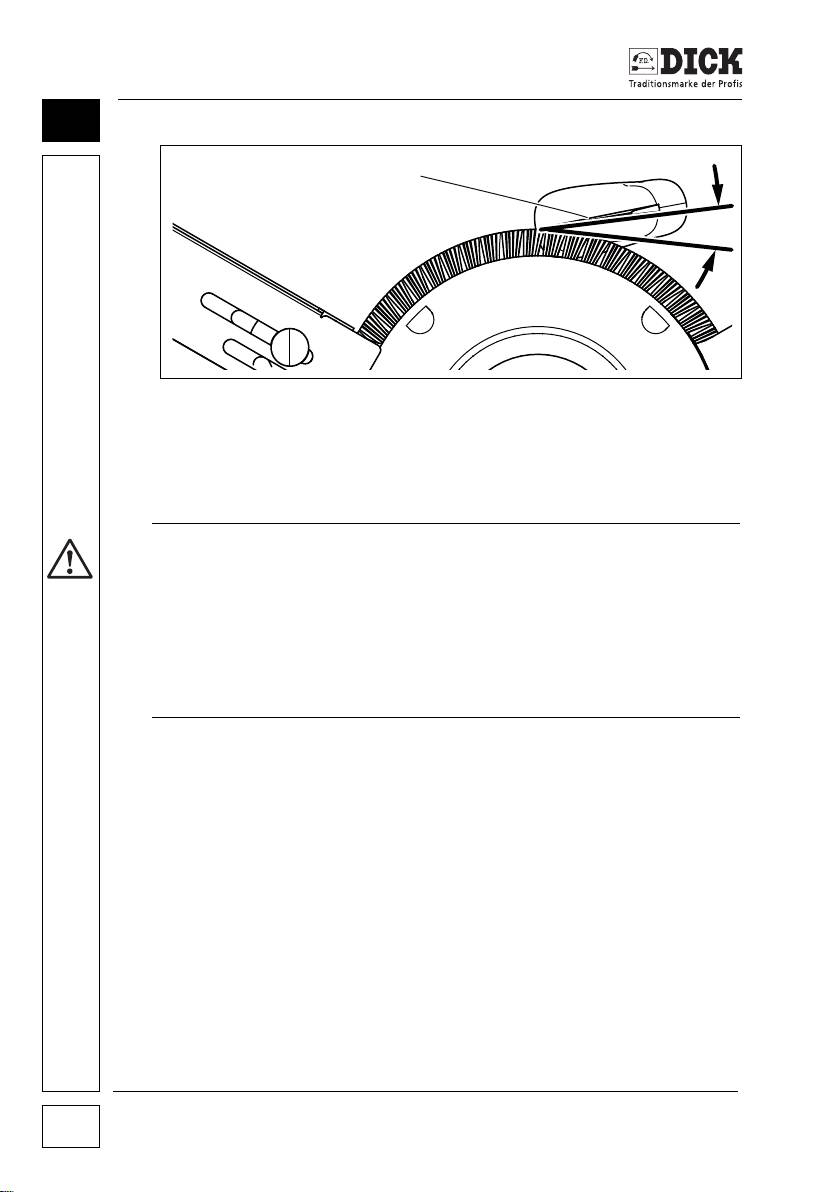

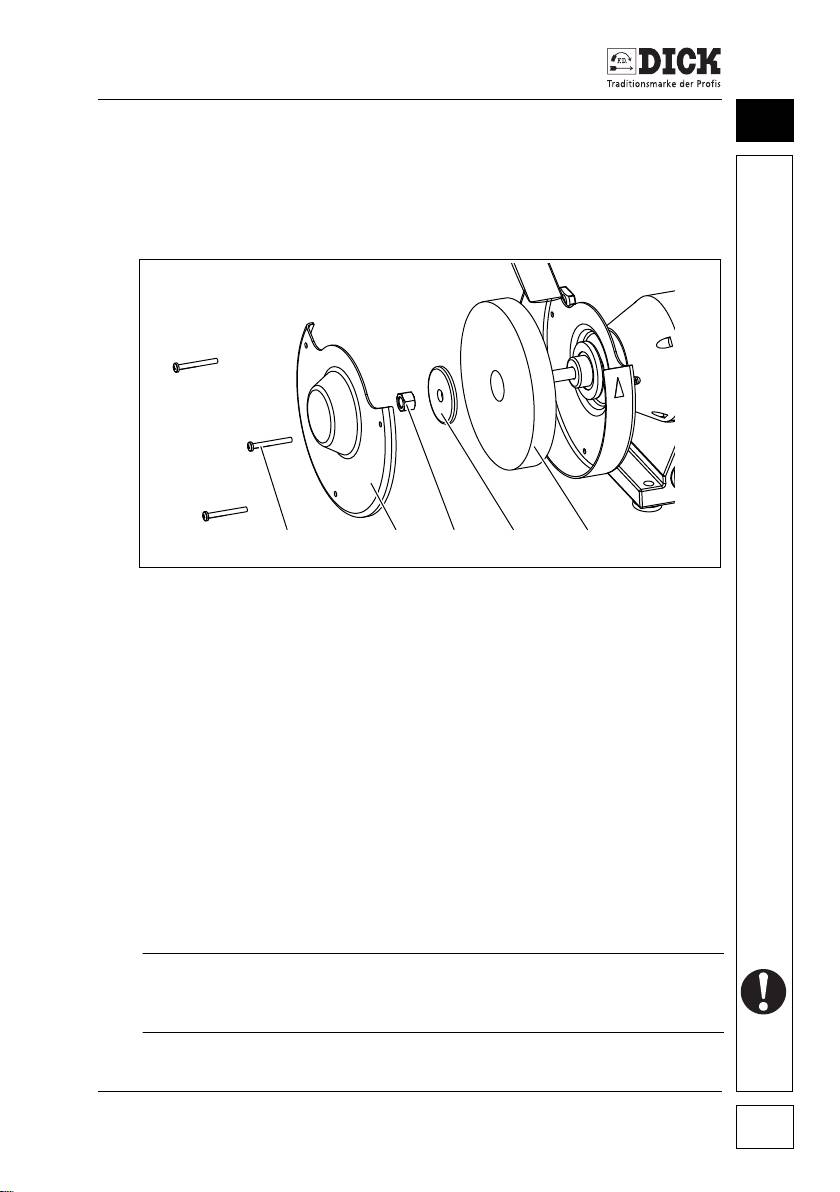

9.2 Changing the lamellar grinding wheel

Change the lamellar grinding wheel as soon as the diameter has

become smaller than the guard.

Replace the lamellar grinding wheel as follows:

SM-90 lamellar grinding machine 27

Servicing and Maintenance

9

1

2

3

45

Figure 9.1 – Cover of the lamellar grinding machine

[1] Flap grinding disc

[2] Cover

[3] Fastening screws

[4] Lock nut M16 LH

[5] Flange cover

1 Undo the fastening screws [3] of the cover [2].

2 Remove the cover [2].

3 Unscrew the nut [4].

Important: Left-hand thread!

4 Remove the flange cover [5].

5 Position the new grinding wheel so that the direction of rota-

tion indicated on the wheel matches the direction of rotation

of the lamellar grinding machine.

6 Install the individual parts in the reverse order.

28

SM-90 lamellar grinding machine

Servicing and Maintenance

9

9.3 Changing the polishing wheel

The polishing wheel must be changed if it is worn to below the wor-

king area.

Replace the polishing wheel as follows:

12345

Figure 9.2 – Polishing wheel

[1] Fastening screws for cover

[2] Cover

[3] Fastening nut

[4] Flange cover

[5] Polishing wheel

1 Undo the fastening screws [1] of the cover [2].

2 Remove the cover [2].

3 Undo the fastening nuts [3] of the flange cover [4].

4 Remove the flange cover [4].

5 Replace the polishing wheel [5].

6 Install the individual parts in the reverse order.

After finishing all repairs and servicing work, check that all

dismantled parts have been completely and correctly installed,

especially the covers.

SM-90 lamellar grinding machine 29

Spare Parts

10

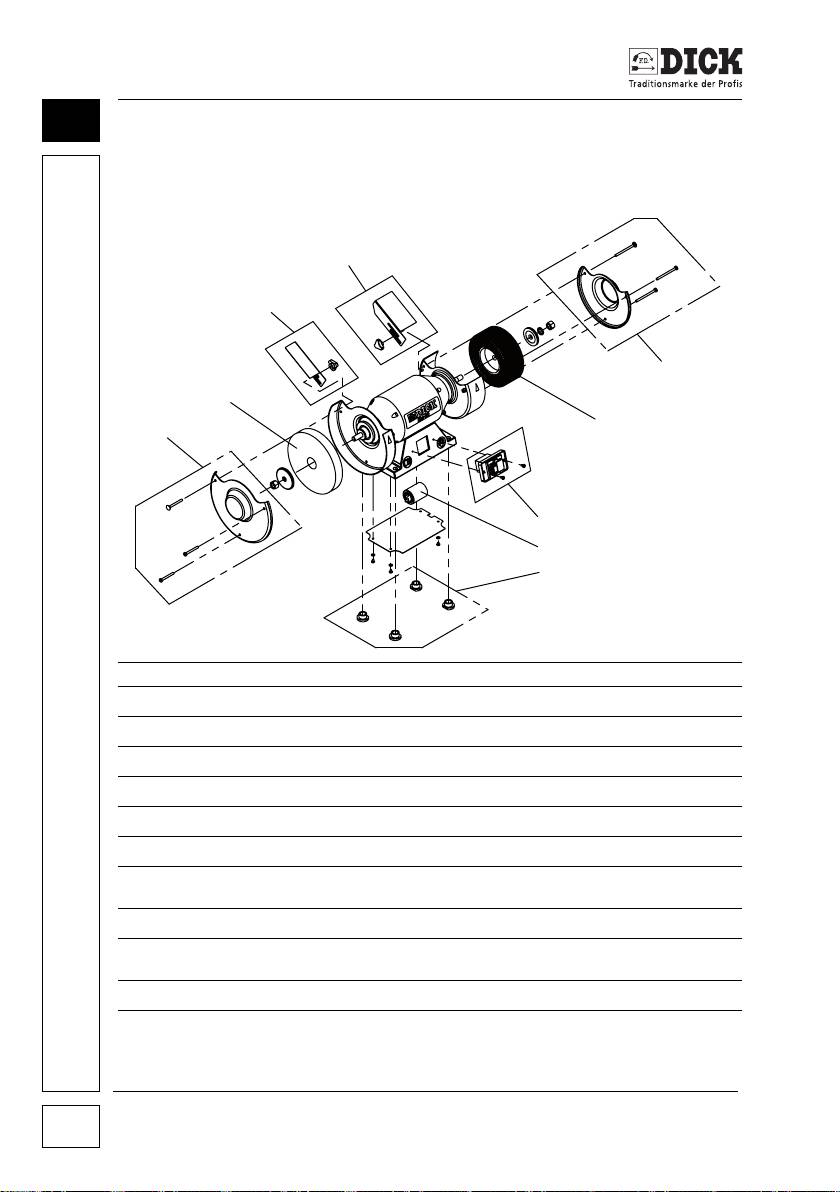

10. Spare Parts

10.1 Spare parts drawing

9 8089 3771

9 8079 3664

9 8089 3773

9 8079 3648

9 8089 3770

9 8079 3660

9 8079 3659

9 8079 3653

9 8079 3650

Order number Quantity Name Dimensions

No. 9 8079 3648 1 no. Polishing wheel ø200 x 25 x ø16

No. 9 8079 3649 1 no. Polishing paste

No. 9 8079 3650 4 no. Machine base

No. 9 8079 3653 1 no. Capacitor 10μF

No. 9 8079 3659 1 Set Switch, complete

No. 9 8079 3660 1 Set Cover, left, complete

No. 9 8079 3664 1 Set Deflection plate, left,

complete

No. 9 8089 3770 1 no. Lamellar grinding wheel ø200 x 50, P120

No. 9 8089 3771 1 Set Deflection plate, right,

complete

No. 9 8089 3773 1 Set Cover, right, complete

No. 9 8089 3774 1 Set Operating instructions SM-90 - 230V D/GB/F/I/E/

RUS

30

SM-90 lamellar grinding machine

Spare Parts

10

10.2 Ordering spare parts

CAUTION

Risk of accidents due to wrong spare parts

Using parts which are not matched to the lamellar grinding

machine constitutes an unassessable risk.

• Use DICK original spare parts only.

Please order spare parts as follows:

Choose the parts to be replaced from the spare parts drawing, with

order number and name.

Your spare part order must include the following details:

1 Required quantities

2 Order number

3 Name

4 Machine type, machine article number, serial number, year

of manufacture (see type plate on back of machine).

Please send your order for spare parts to your specialist dealer or

to:

Friedr. Dick GmbH & Co. KG

Postfach 1173

73777 Deizisau

GERMANY

Tel.: (+49) (0)7153 817-0

Fax: (+49) (0)7153 817-218 oder -219

E-mail: mail@dick.de

Web: www.dick.de

SM-90 lamellar grinding machine 31

EC Declaration of Conformity

11

11. EC Declaration of Conformity

Manufacturer

Friedr. Dick GmbH & Co. KG

Esslinger Str. 4-10

73779 Deizisau

GERMANY

We herewith declare, in sole responsibility that the following product:

Lamellar grinding machine - Type SM-90

with the serial number given on the lamellar grinding machine’s

type plate, conforms to the following EC Directives:

EC Machinery Directive (2006/42/EC),

EC EMC Directive (2004/108/EC).

European standards applied:

• EN ISO 12100:2010

• EN 60204-1:2006

• EN 61029-1:2009+A11:2010

• EN 61029-2-4:2011

• EN 61000-3-2:2006+A1:2009+A2:2009

• EN 61000-3-3:2008

• EN 55014-1:2006+A1:2009+A2:2011

• EN 55014-2:1997+A1:2001+A2:2008

The person authorised to compile the technical documents

(technical file) at Friedr. Dick GmbH & Co. KG is Dipl. Ing.

Horst Löhnert.

32

SM-90 lamellar grinding machine