Partner P350S 2014: instruction

Class: Country house and garden equipment

Type: Petrol tool/petrol trimmer

Manual for Partner P350S 2014

P350S

INSTRUCTION MANUAL

IMPORTANT INFORMATION

: Please read these instructions carefully and make

GB

sure you understand them before using this unit. Retain these instructions for future

reference.

ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ

ВАЖНАЯ ИНФОРМАЦИЯ:

Пожалуйста, внимательно прочтите данную

RU

инструкцию перед тем, как приступить к зксппуатации триммера, и убедитесь что

она вам понятна. Сохраните инструкцию для дальнейшего обращения к ней.

ANVÄNDARHANDBOK

VIKTIG INFORMATION

: Läs dessa anvisningar noggrant och se till att du förstår

SE

dem innan du använder trimmeren och spara dem för framtida behov.

BRUKERHÅNDBOK

VIKTIG INFORMASJON:

Vennligst les disse instruksjonene nøye og pass på at De

NO

forstår dem før De bruker trimmeren og oppbevar den for senere bruk.

BRUGERHÅNDBOG

VIGTIGE OPLYSNINGER:

Læs venligst disse instruktioner omhyggeligt og vær

DK

sikker på, at De forstår dem, før De anvender græstrimmeren og gemme til senere

henvisning.

KÄYTTÖOHJEKIRJA

TÄRKEÄÄ:

Lue tämä ohjekirja huolellisesti läpi ennen kuin alat käyttää laitetta.

FI

Säilytä ohjekirja myöhempää käyttöä varten.

INSTRUKCJA OBSŁUGI

WAZNE INFORMACJE:

Przed rozpoczęciem użytkowania urządzenia, należy

PL

uważnie przeczytać i zrozumieć ninijszą instrukcją. Instrukcje należy przechowywać

do późniejszego z niej korzystania.

NÁVOD K POUŽĺVÁNĺ

DŮLEŽITÁ INFORMACE:

Prosíme, než začnete zařízení používat, přečtěte si

CS

pečlivě tyto pokyny a ujistěte se, že jim plně rozumíte.

9096-312006 Rev. 5 12/11/13

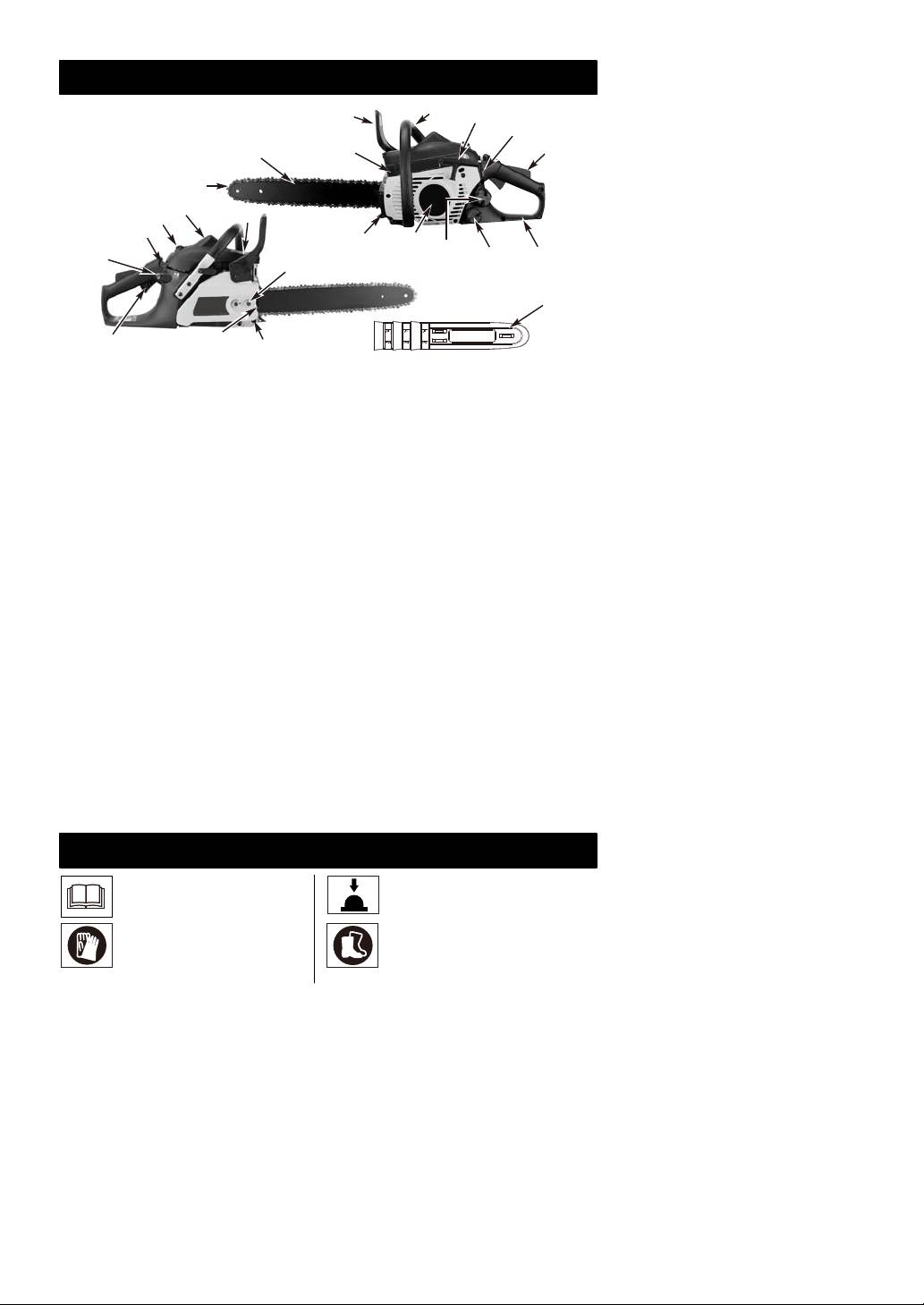

IDENTIFICATION (WHAT IS WHAT?)

5

4

6

7

3

8

2

1

16

17

15

18

13

12

11

19

10

9

14

23

20

21

22

1. Saw chain

9. Rear Handle / Boot Loop

18. Choke Lever for Auto

2. Guide Bar

10. Oil Tank cap

Choke

3. Spark Arrester Screen

11. Fuel Tank Cap

19. Primer Bulb

4. Chain Brake Lever / Hand

12. Starter Cover

20. Throttle trigger

Guard

13. Spiked Bumper

21. Saw Chain Adjustment

5. Front Handle

14. Bar Retaining Nuts

Screw

6. Starter Handle

15. Muffler Shield

22. Chain Catcher

7. ON/OFF Switch

16. Spark Plug

23. Guide-bar Cover

8. Throttle trigger lockout

17. Air Cleaner Cover

SAFETY FEATURES

Numbers preceding the descriptions correspond with the numbers above to help you locate

the safety feature.

1 LOW KICKBACK SAW CHAIN helps

4 CHAIN BRAKE is a safety feature

significantly reduce kickback, or the

designed to reduce the possibility of

intensity of kickback, due to specially

injury due to kickback by stopping a

designed depth gauges and guard

moving saw chain in milliseconds. It is

links.

activated by the CHAIN BRAKE lever.

3 SPARK ARRESTER SCREEN retains

7 STOP SWITCH immediately stops

carbon and other flammable

the engine when tripped. Stop switch

particles over 0.023 inches (0.6mm)

must be pushed to ON position to start

in size from engine exhaust flow.

or restart engine.

Compliance with local, state and

8 THROTTLE TRIGGER LOCKOUT

federal laws and/or regulations

prevents accidental acceleration of the

governing the use of a spark arrester

engine. Throttle trigger (20) cannot be

screen is the user’s responsi-

squeezed unless the safety latch is

bility. See Safety Precautions for

depressed.

additional

information.

22 CHAIN CATCHER reduces the danger

4 CHAIN BRAKE LEVER / HAND

of injury in the event saw chain breaks

GUARD protects the operator’s left

or derails during operation. The chain

hand in the event it slips off the front

catcher is designed to intercept a

handle while saw is running.

whipping chain.

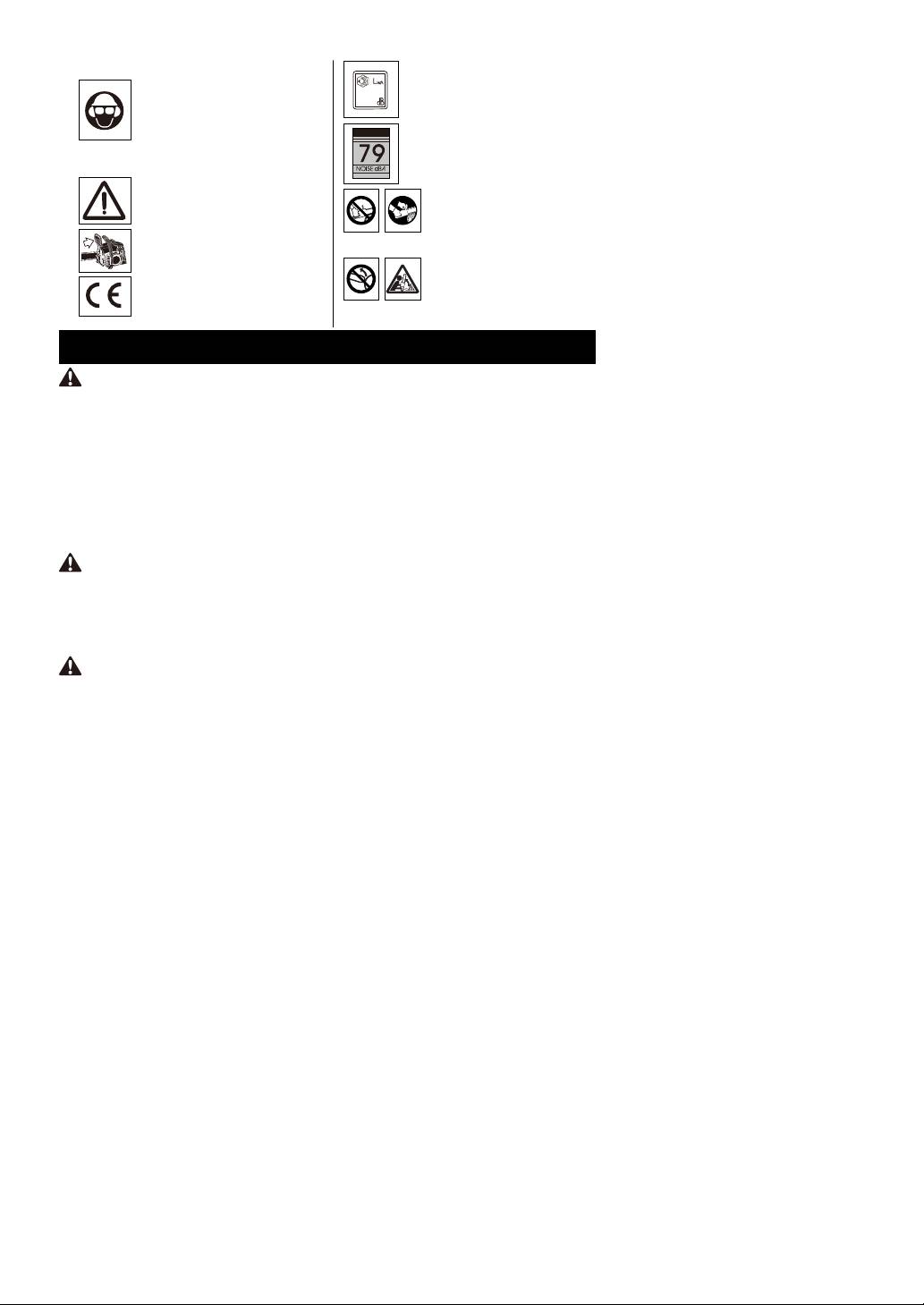

IDENTIFICATION OF SYMBOLS

Read and understand the Instr-

uction Manual and all warning

Primer Bulb

labels before using the machine.

Wear gloves to protect

Wear safety boots to protect

your hands

your feet

-- 2 --

Whenever the machine is in use,

Guaranteed sound power level

safety glasses must be worn to

LWA accordance with directive

safeguard against flying objects.

2000/14/EC + 2005/88/EC

Ear protection must also be used

in order to protect to operators

hearing. If the operator is

working in an area where there is

Sound pressure level at 7,5

a risk of falling objects a safety

meters

helmet must also be worn.

WARNING:

Always use two hands when

Danger

operating the chain saw.

Make Sure the Chain Brake is

disengaged! Pull Hand Guard/

Chain Brake back to run.

This product is in accordance

with applicable EC directives.

SAFETY RULES

• DO NOT allow other persons to be near

WARNING: This tool is designed

when starting or cutting with the chain

only for use by one operator and intended

saw. Keep bystanders and animals out of

for forest work. This tool is designed only to

the work area.

be operated with the right hand on the rear

• DO NOT start cutting until you have a

handle and the left hand on the front handle.

clear work area, secure footing, and a

The operator must read and understood the

planned retreat path from the falling tree.

safety requirements in the instruction

• Keep all parts of your body away from the

handbook and using the appropriate

saw chain when the engine is running.

personal protective equipment (PPE) before

• Before you start the engine, make sure

operating this tool. This tool is not designed

that the saw chain is not contacting

for cutting unintended material, such as

anything.

rubber, stone, metals or wood products not

• Carry the chain saw with the engine

clear of foreign objects.

stopped, the guide bar and saw chain to

the rear, and the muffler away from your

WARNING: When using gas tools,

body.

basic safety precautions, including the

• DO NOT operate a chain saw that is

following, should always be followed to

damaged, improperly adjusted, or not

reduce the risk of serious personal injury

completely and securely assembled. Be

and/or damage to the unit. Read all these

sure that the saw chain stops moving

instructions before operating this product

when the throttle control trigger is

and save these instructions.

released.

WARNING: This machine produces

• Shut off the engine before setting the

an electromagnetic field during operation.

chain saw down.

This field may under some circumstances

• Use extreme caution when cutting small

interfere with active or passive medical

size brush and saplings because slender

implants. To reduce the risk of serious or

material may catch the saw chain and be

fatal injury, we recommend persons with

whipped toward you or pull you off

medical implants to consult their physician

balance.

and the medical implant manufacturer

• When cutting a limb that is under tension,

before operating this machine.

be alert for springback so that you will

not be struck when the tension in the

• DO NOT operate a chain saw with one

wood fibers is released.

hand! Serious injury to the operator,

• Keep the handles dry, clean, and free of

helpers, bystanders, or any combination

oil or fuel mixture.

of these persons may result from one-

• Operate the chain saw only in

handed operation. A chain saw is

well-ventilated areas.

intended for two-handed use.

• DO NOT operate a chain saw in a tree

• DO NOT operate a chain saw when you

unless you have been specifically trained

are fatigued, under the influence of drugs,

to do so.

alcohol or medication.

• All chain saw service, other than the

• Use safety footwear, snug-fitting clothing,

items listed in the user manual safety and

protective gloves, and eye, hearing

maintenance instructions, should be

and head protection devices.

performed by competent chain saw

• Use caution when handling fuel. To

service personnel.

avoide fire, move the chain saw at least

• When transporting your chain saw, use

10 feet (3m) from the fueling point before

the appropriate guide bar scabbard.

starting the engine.

-- 3 --

108

WARNING! Contacting the

guide bar tip with any object

should be avoided; tip contace

may cause the guide bar to

move suddenly upward and

backward. which may cause

serious injury.

Table of contents

- IDENTIFICATION (WHAT IS WHAT?)

- SAFETY RULES

- KICKBACK SAFETY PRECAUTIONS

- IMPORTANT SAFETY

- FUEL AND LUBRICATION

- OPERATION

- GENERAL CUTTING INSTRUCTIONS

- MAINTENANCE INSTRUCTIONS

- DECLARATION OF CONFORMITY

- TECHNICAL DATA SHEET

- ОПИСАНИЕ ДЕТАЛЕЙ ИНСТРУМЕНТА

- ПРАВИЛА ТЕХНИКИ БЕЗОПАСНОСТИ

- МЕРЫ ПРЕДОСТОРОЖНОСТИ ДЛЯ ПРЕДОТВРАЩЕНИЯ ОТСКОКА

- ВАЖНЫЕ СВЕДЕНИЯ, КАСАЮЩИЕСЯ БЕЗОПАСНОСТИ

- ТОПЛИВО И СМАЗКА

- ЭКСПЛУАТАЦИЯ

- ОБЩИЕ ИНСТРУКЦИИ ПО ПИЛЕНИЮ

- ИНСТРУКЦИИ ПО ТЕХНИЧЕСКОМУ ОБСЛУЖИВАНИЮ

- ДЕКЛАРАЦИЯ О СООТВЕТСТВИИ СТАНДАРТАМ

- ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

- IDENTIFIERING (VAD ÄR VAD?)

- SÄKERHETSREGLER

- SÄKERHETSÅTGÄRDER MOT KAST

- VIKTIG SÄKERHET

- BRÄNSLE OCH SMÖRJNING

- ANVÄNDNING

- ALLMÄNNA SÅGNINGSANVISNINGAR

- UNDERHÅLLSINSTRUKTIONER

- FÖRSÄKRAN OM ÖVERENSSTÄMMELSE

- TEKNISKT DATABLAD

- IDENTIFIKASJON (HVA ER HVA?)

- SIKKERHETSREGLER

- SIKKERHETSFORANSTALTNINGER FOR TILBAKESLAG

- VIKTIG SIKKERHET

- DRIVSTOFF OG SMØRING

- DRIFT

- GENERELLE INSTRUKSJONER FOR KUTTING

- INSTRUKSJONER FOR VEDLIKEHOLD

- SAMSVARSERKLÆRING

- TECHNICAL DATA SHEET

- IDENTIFICERING (HVAD ER HVAD?)

- SIKKERHEDSREGLER

- SIKKERHEDSFORANSTALTNINGER VEDRØRENDE TILBAGESLAG

- VIGTIGE SIKKERHEDSOPLYSNINGER

- BRÆNDSTOF OG SMØRING

- BETJENING

- GENERELLE VEJLEDNINGER TIL SAVNING

- VEDLIGEHOLDELSESANVISNINGER

- TEKNISK DATAARK

- TUNNISTUS (MIKÄ ON OLEELLISTA?)

- TURVAOHJEET

- TAKAPOTKUJEN TURVALLISUUSVAROTOIMENPITEET

- TÄRKEÄ TURVALLISUUS

- POLTTOAINE JA VOITELU

- KÄYTTÖ

- YLEISIÄ SAHAUSOHJEITA

- HUOLTO-OHJEET

- TEKNISTEN TIETOJEN LEHTI

- IDENTYFIKACJA (CO TO JEST?)

- ZASADY BEZPIECZEŃSTWA

- ŚRODKI BEZPIECZEŃSTWA DOTYCZĄCE ODBIĆ

- WAŻNE INSTRUKCJE DOTYCZĄCE BEZPIECZEŃSTWA

- PALIWO I SMAROWANIE

- OPERACJE

- OGÓLNE INSTRUKCJE CIĘCIA

- INSTRUKCJE KONSERWACJI

- DEKLARACJA ZGODNOŚCI

- ARKUSZ DANYCH TECHNICZNYCH

- IDENTIFIKACE (CO JE CO?)

- BEZPEČNOSTNÍ PRAVIDLA

- BEZPEČNOSTNÍ ZÁSADY PROTI ZPĚTNÉMU RÁZU

- DŮLEŽITÉ INFORMACE O BEZPEČNOSTI

- PALIVO A MAZÁNÍ

- POUŽITÍ

- OBECNÉ POKYNY PRO ŘEZÁNÍ

- POKYNY PRO ÚDRŽBU

- PROHLÁŠENÍ SHODY

- TECHNICKÉ ÚDAJE