Hypertherm Phoenix V9.76.0: instruction

Class: Software

Type:

Manual for Hypertherm Phoenix V9.76.0

Safety and Compliance Manual

WARNING!

Failure to follow operating instructions could result in personal injury or damage

to equipment.

80669C | Revision 2

Powermax and Hypertherm are trademarks of Hypertherm Inc. and may be registered in the United States and other countries. All other

trademarks are the property of their respective holders.

© 2015 Hypertherm Inc.

Hypertherm Inc.

Hypertherm Europe B.V.

Etna Road, P.O. Box 5010

Vaartveld 9

Hanover, NH 03755 USA

4704 SE

603-643-3441 Tel (Main Office)

Roosendaal, Nederland

603-643-5352 Fax (All Departments)

31 165 596907 Tel

info@hypertherm.com (Main Office Email)

31 165 596901 Fax

800-643-9878 Tel (Technical Service)

31 165 596908 Tel (Marketing)

technical.service@hypertherm.com (Technical Service Email)

31 165 596900 Tel (Technical Service)

800-737-2978 Tel (Customer Service)

00 800 4973 7843 Tel (Technical Service)

customer.service@hypertherm.com (Customer Service Email)

866-643-7711 Tel (Return Materials Authorization)

Hypertherm Japan Ltd.

877-371-2876 Fax (Return Materials Authorization)

Level 9, Edobori Center Building

return.materials@hypertherm.com (RMA email)

2-1-1 Edobori, Nishi-ku

Osaka 550-0002 Japan

Hypertherm Plasmatechnik GmbH

81 6 6225 1183 Tel

Technologiepark Hanau

81 6 6225 1184 Fax

Rodenbacher Chaussee 6

D-63457 Hanau-Wolfgang, Deutschland

Hypertherm Brasil Ltda.

49 6181 58 2100 Tel

Rua Bras Cubas, 231 – Jardim Maia

49 6181 58 2134 Fax

Guarulhos, SP - Brasil

49 6181 58 2123 (Technical Service)

CEP 07115-030

55 11 2409 2636 Tel

Hypertherm (S) Pte Ltd.

55 11 2408 0462 Fax

82 Genting Lane

Media Centre

Hypertherm México, S.A. de C.V.

Annexe Block #A01-01

Avenida Toluca No. 444, Anexo 1,

Singapore 349567, Republic of Singapore

Colonia Olivar de los Padres

65 6841 2489 Tel

Delegación Álvaro Obregón

65 6841 2490 Fax

México, D.F. C.P. 01780

65 6841 2489 (Technical Service)

52 55 5681 8109 Tel

52 55 5683 2127 Fax

Hypertherm (Shanghai) Trading Co., Ltd.

Unit 301, South Building

Hypertherm Korea Branch

495 ShangZhong Road

#3904 Centum Leaders Mark B/D,

Shanghai, 200231

1514 Woo-dong, Haeundae-gu, Busan

PR China

Korea, 612-889

86-21-60740003 Tel

82 51 747 0358 Tel

86-21-60740393 Fax

82 51 701 0358 Fax

Contents

English ................................................................................................................................................................SC-5

Бългapcки / Bulgarian ................................................................................................................................SC-17

/ Simplified Chinese ..................................................................................................................SC-29

/ Traditional Chinese .................................................................................................................SC-41

Česky / Czech ...............................................................................................................................................SC-51

Dansk / Danish ..............................................................................................................................................SC-63

Nederlands / Dutch ......................................................................................................................................SC-75

Suomi / Finnish ..............................................................................................................................................SC-87

Français / French ..........................................................................................................................................SC-99

Deutsch / German ......................................................................................................................................SC-111

Ελληνικά / Greek ........................................................................................................................................SC-123

Magyar / Hungarian ....................................................................................................................................SC-135

Italiano / Italian .............................................................................................................................................SC-147

日本語 / Japanese ......................................................................................................................................SC-159

/ Korean ..........................................................................................................................................SC-171

Norsk / Norwegian ......................................................................................................................................SC-183

Polski / Polish ..............................................................................................................................................SC-195

Português / Portuguese ............................................................................................................................SC-207

Romană / Romanian ...................................................................................................................................SC-219

Русский / Russian ......................................................................................................................................SC-231

Srpski / Serbian ...........................................................................................................................................SC-245

Slovenščina / Slovenian ............................................................................................................................SC-257

Español / Spanish .......................................................................................................................................SC-269

Svenska / Swedish .....................................................................................................................................SC-281

Türkçe / Turkish ...........................................................................................................................................SC-293

Safety and Compliance 80669C 3

Contents

4 Safety and Compliance 80669C

WARNING!

Failure to follow operating instructions could result in personal

injury or damage to equipment.

Safety and Compliance Manual

806690 Revision 2 – January 2015

English

Safety

DANGER WARNING CAUTION

RECOGNIZE SAFETY

American National Standards Institute (ANSI) guidelines are used for

INFORMATION

safety signal words and symbols. The signal word DANGER or

WARNING is used with a safety symbol. DANGER identifies the most

The symbols shown in this section are used to identify potential

serious hazards.

hazards. When you see a safety symbol in this manual or on your

• DANGER and WARNING safety labels are located on your machine

machine, understand the potential for personal injury, and follow the

near specific hazards.

related instructions to avoid the hazard.

• DANGER safety messages precede related instructions in the

manual that will result in serious injury or death if not followed

FOLLOW SAFETY

correctly.

INSTRUCTIONS

• WARNING safety messages precede related instructions in this

manual that may result in injury or death if not followed correctly.

Carefully read all safety messages in this manual and safety labels

• CAUTION safety messages precede related instructions in this

on your machine.

manual that may result in minor injury or damage to equipment if not

followed correctly.

• Keep the safety labels on your machine in good condition.

Replace missing or damaged labels immediately.

INSPECT EQUIPMENT BEFORE USING

• Learn how to operate the machine and how to use the controls

properly. Do not let anyone operate it without instruction.

All cutting equipment must be inspected as required to make sure it is in

• Keep your machine in proper working condition. Unauthorized

safe operating condition. When found to be incapable of reliable and

modifications to the machine may affect safety and machine

safe operation, the equipment must be repaired by qualified personnel

service life.

prior to its next use or withdrawn from service.

Safety and Compliance SC-5

English

Safety

RESPONSIBILITY FOR SAFETY

The person or entity responsible for the safety of the workplace must:

• Select contractors who provide trained and qualified personnel, and

• Make sure that operators and their supervisors are trained in the safe

who have awareness of the risks involved, to do cutting.

use of their equipment, the safe use of the process, and emergency

• Tell contractors about flammable materials or hazardous conditions

procedures.

that are specific to the site, or hazardous conditions that they may not

• Make sure that all hazards and safety precautions identified herein

be aware of.

are communicated to and understood by workers before the start of

• Make sure that the quality and quantity of air for ventilation is such

work.

that personnel exposures to hazardous contaminants are below the

• Designate approved cutting areas and establish procedures for safe

allowable limits.

cutting.

• Make sure that ventilation in confined spaces is sufficient to allow

• Be responsible for authorizing cutting operations in areas not

adequate oxygen for life support, to prevent accumulation of

specifically designed or approved for such processes.

asphixiants or flammable explosive mixtures, to prevent

oxygen-enriched atmospheres, and to keep airborne contaminants in

• Make sure that only approved equipment, such as torches and

breathing atmospheres below allowable limits.

personal protective equipment, are used.

A PLASMA ARC CAN DAMAGE FROZEN PIPES

Frozen pipes may be damaged or can burst if you attempt to thaw them with a plasma torch.

STATIC ELECTRICITY CAN DAMAGE PRINTED CIRCUIT BOARDS

Use proper precautions when handling printed circuit boards:

• Store printed circuit boards in anti-static containers.

• Wear a grounded wrist strap when handling printed circuit boards.

GROUNDING SAFETY

Work lead Attach the work lead securely to the workpiece or the

Input power

cutting table with good metal-to-metal contact. Do not connect it to

• Make sure to connect the power cord ground wire to the ground in

the piece that will fall away when the cut is complete.

the disconnect box.

Cutting table Connect the cutting table to an earth ground, in

• If installation of the plasma system involves connecting the power

accordance with appropriate national and local electrical regulations.

cord to the power supply, make sure to connect the power cord

ground wire properly.

• Place the power cord’s ground wire on the stud first, then place any

other ground wires on top of the power cord ground. Tighten the

retaining nut.

• Tighten all electrical connections to avoid excessive heating.

ELECTRICAL HAZARDS

• Only trained and authorized personnel may open this equipment.

• If the equipment must have power when the enclosure is open for

• If the equipment is permanently connected, turn it off, and lock

servicing, arc flash explosion hazards may exist. Follow all local

out/tag out power before the enclosure is opened.

requirements (NFPA 70E in the USA) for safe work practices and for

personal protective equipment when servicing energized equipment.

• If power is supplied to the equipment with a cord, unplug the unit

before the enclosure is opened.

• Prior to operating the equipment after moving, opening, or servicing,

make sure to close the enclosure and make sure that there is proper

• Lockable disconnects or lockable plug covers must be provided by

earth ground continuity to the enclosure.

others.

• Always follow these instructions for disconnecting power before

• Wait 5 minutes after removal of power before entering the enclosure

inspecting or changing torch consumable parts.

to allow stored energy to discharge.

SC-6 Safety and Compliance

English

Safety

ELECTRIC SHOCK CAN KILL

Touching live electrical parts can cause a fatal shock or severe burn.

• Install and ground this equipment according to the instruction

manual and in accordance with national and local regulations.

• Operating the plasma system completes an electrical circuit

between the torch and the workpiece. The workpiece and anything

• Inspect the input power cord frequently for damage or cracking

touching the workpiece are part of the electrical circuit.

of the cover. Replace a damaged power cord immediately.

Bare wiring can kill.

• In machine torch applications, never touch the torch body,

workpiece, or water in a water table when the plasma system is

• Inspect and replace any worn or damaged torch leads.

operating.

• Do not pick up the workpiece, including the waste cutoff, while you

cut. Leave the workpiece in place or on the workbench with the

Electric shock prevention

work lead attached during the cutting process.

All plasma systems use high voltage in the cutting process

• Before checking, cleaning, or changing torch parts, disconnect the

(200 to 400 VDC are common). Take the following

main power or unplug the power supply.

precautions when operating this system:

• Never bypass or shortcut the safety interlocks.

• Wear insulated gloves and boots, and keep your body and clothing

• Before removing any power supply or system enclosure cover,

dry.

disconnect electrical input power. Wait 5 minutes after

• Do not stand, sit, or lie on – or touch – any wet surface when using

disconnecting the main power to allow capacitors to discharge.

the plasma system.

• Never operate the plasma system unless the power supply covers

• Insulate yourself from the work and ground using dry insulating

are in place. Exposed power supply connections present a severe

mats or covers big enough to prevent any physical contact with the

electrical hazard.

work or ground. If you must cut in or near a damp area, use

• When making input connections, attach a proper grounding

extreme caution.

conductor first.

• Provide a disconnect switch close to the power supply with

• Each plasma system is designed to be used only with specific

properly sized fuses. This switch allows the operator to turn off the

torches. Do not substitute other torches, which could overheat and

power supply quickly in an emergency situation.

present a safety hazard.

• When using a water table, make sure that it is correctly connected

to an earth ground.

CUTTING CAN CAUSE FIRE OR EXPLOSION

Fire prevention

WARNING

• Make sure the cutting area is safe before doing any cutting. Keep a

Explosion Hazard

fire extinguisher nearby.

Argon-Hydrogen and Methane

• Remove all flammables within 35 feet (10 m) of the cutting area.

Hydrogen and methane are flammable gases that present an

• Quench hot metal or allow it to cool before handling or before

explosion hazard. Keep flames away from cylinders and hoses that

letting it touch combustible materials.

contain methane or hydrogen mixtures. Keep flames and sparks away

• Never cut containers with potentially flammable materials inside –

from the torch when using methane or argon-hydrogen plasma.

they must be emptied and properly cleaned first.

WARNING

• Ventilate potentially flammable atmospheres before cutting.

Hydrogen Detonation with

• When cutting with oxygen as the plasma gas, an exhaust ventilation

Aluminum Cutting

system is required.

• Do not cut aluminum underwater or with water touching the

underside of the aluminum.

Explosion prevention

• Cutting aluminum underwater or with the water touching the

• Do not use the plasma system if explosive dust or vapors may be

underside of the aluminum can result in an explosive condition that

present.

can detonate during plasma cutting operations.

• Do not cut pressurized cylinders, pipes, or any closed containers.

WARNING

• Do not cut containers that have held combustible materials.

Explosion Hazard

Underwater Cutting with Fuel Gases

• Do not cut underwater with fuel gases containing hydrogen.

• Cutting underwater with fuel gases containing hydrogen can

result in an explosive condition that can detonate during plasma

cutting operations.

Safety and Compliance SC-7

English

Safety

COMPRESSED GAS EQUIPMENT

GAS CYLINDERS CAN

SAFETY

EXPLODE IF DAMAGED

• Never lubricate cylinder valves or regulators with oil or grease.

Gas cylinders contain gas under high pressure. If damaged, a

• Use only correct gas cylinders, regulators, hoses, and fittings

cylinder can explode.

designed for the specific application.

• Handle and use compressed gas cylinders in accordance with

• Maintain all compressed gas equipment and associated parts in

applicable national and local regulations.

good condition.

• Never use a cylinder that is not upright and secured in place.

• Label and color-code all gas hoses to identify the type of gas in

• Keep the protective cap in place over the valve except when the

each hose. Consult applicable national and local regulations.

cylinder is in use or connected for use.

• Never allow electrical contact between the plasma arc and a

cylinder.

• Never expose cylinders to excessive heat, sparks, slag, or open

flame.

• Never use a hammer, wrench, or other tool to open a stuck cylinder

valve.

TOXIC FUMES CAN CAUSE INJURY OR DEATH

The plasma arc by itself is the heat source used for cutting.

The air quality level in any relevant workplace depends on site-specific

Accordingly, although the plasma arc has not been identified as a

variables such as:

source of toxic fumes, the material being cut can be a source of toxic

• Table design (wet, dry, underwater).

fumes or gases that deplete oxygen.

• Material composition, surface finish, and composition of coatings.

The fumes produced vary depending on the metal that is cut. Metals

• Volume of material removed.

that may release toxic fumes include, but are not limited to, stainless

• Duration of cutting or gouging.

steel, carbon steel, zinc (galvanized), and copper.

• Size, air volume, ventilation, and filtration of the workplace.

In some cases, the metal may be coated with a substance that could

• Personal protective equipment.

release toxic fumes. Toxic coatings include, but are not limited to,

• Number of welding and cutting systems in operation.

lead (in some paints), cadmium (in some paints and fillers), and

• Other workplace processes that may produce fumes.

beryllium.

If the workplace must conform to national or local regulations, only

The gases produced by plasma cutting vary based on the material to

monitoring or testing done at the site can determine whether the

be cut and the method of cutting, but may include ozone, oxides of

workplace is above or below allowable levels.

nitrogen, hexavalent chromium, hydrogen, and other substances if

To reduce the risk of exposure to fumes:

such are contained in or released by the material being cut.

• Remove all coatings and solvents from the metal before cutting.

Caution should be taken to minimize exposure to fumes produced by

• Use local exhaust ventilation to remove fumes from the air.

any industrial process. Depending on the chemical composition and

• Do not inhale fumes. Wear an air-supplied respirator when cutting

concentration of the fumes (as well as other factors, such as

any metal coated with, containing, or suspected to contain toxic

ventilation), there may be a risk of physical illness, such as birth

elements.

defects or cancer.

• Make sure that those using welding or cutting equipment, as well as

It is the responsibility of the equipment and site owner to test the air

air-supplied respiration devices, are qualified and trained in the

quality in the cutting area and to make sure that the air quality in the

proper use of such equipment.

workplace meets all local and national standards and regulations.

• Never cut containers with potentially toxic materials inside. Empty

and properly clean the container first.

• Monitor or test the air quality at the site as needed.

• Consult with a local expert to implement a site plan to make sure air

quality is safe.

SC-8 Safety and Compliance

English

Safety

A PLASMA ARC CAN CAUSE INJURY AND BURNS

Instant-on torches

The plasma arc will cut quickly through gloves and skin.

• Keep away from the torch tip.

A plasma arc ignites immediately when the torch switch is activated.

• Do not hold metal near the cutting path.

• Never point the torch toward yourself or others.

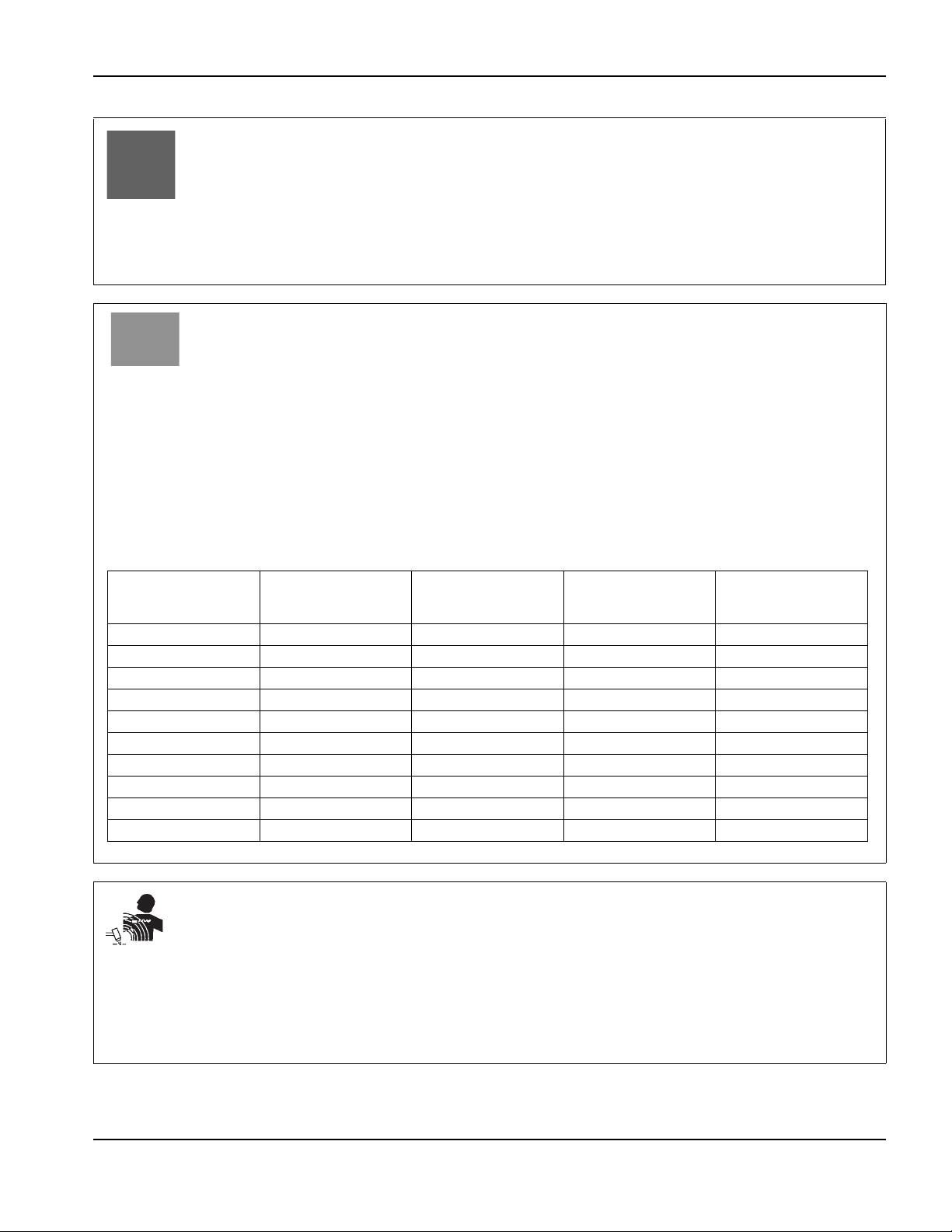

ARC RAYS CAN BURN EYES AND SKIN

Minimum protective

Suggested shade

OSHA 29CFR

Europe

Arc current

shade number

number for comfort

1910.133(a)(5)

EN168:2002

(ANSIZ49.1:2012)

(ANSI Z49.1:2012)

Less than 40 A 5 5 8 9

41 A to 60 A 6 6 8 9

61 A to 80 A 8 8 8 9

81 A to 125 A 8 9 8 9

126 A to 150 A 8 9 8 10

151 A to 175 A 8 9 8 11

176 A to 250 A 8 9 8 12

251 A to 300 A 8 9 8 13

301 A to 400 A 9 12 9 13

401 A to 800 A101410N/A

PACEMAKER AND HEARING AID OPERATION

Pacemaker and hearing aid operation can be affected by magnetic

To reduce magnetic field hazards:

fields from high currents.

• Keep both the work lead and the torch lead to one side, away from

your body.

Pacemaker and hearing aid wearers should consult a doctor before

• Route the torch leads as close as possible to the work lead.

going near any plasma arc cutting and gouging operations.

• Do not wrap or drape the torch lead or work lead around your body.

• Keep as far away from the power supply as possible.

Safety and Compliance SC-9

English

Eye protection Plasma arc rays produce intense visible and invisible

• Wear flame-retardant clothing to cover all exposed areas.

(ultraviolet and infrared) rays that can burn eyes and skin.

• Wear cuffless trousers to prevent entry of sparks and slag.

• Use eye protection in accordance with applicable national and local

Also, remove any combustibles, such as a butane lighter or matches,

regulations.

from your pockets before cutting.

• Wear eye protection (safety glasses or goggles with side shields,

and a welding helmet) with appropriate lens shading to protect your

Cutting area Prepare the cutting area to reduce reflection and

eyes from the arc’s ultraviolet and infrared rays.

transmission of ultraviolet light:

• Paint walls and other surfaces with dark colors to reduce reflection.

Skin protection Wear protective clothing to protect against burns

caused by ultraviolet light, sparks, and hot metal.

• Use protective screens or barriers to protect others from flash

and glare.

• Wear gauntlet gloves, safety shoes, and hat.

• Warn others not to watch the arc. Use placards or signs.

Safety

NOISE CAN DAMAGE HEARING

Cutting with a plasma arc can exceed acceptable noise levels as

Use ear protectors if the noise is disruptive or if there is a risk of

defined by local regulations in many applications. Prolonged exposure

hearing damage after all other engineering and administrative

to excessive noise can damage hearing. Always wear proper ear

controls have been implemented. If hearing protection is required,

protection when cutting or gouging, unless sound pressure level

wear only approved personal protective equipment such as ear muffs

measurements taken at the site have verified personal hearing

or ear plugs with a noise reduction rating appropriate for the

protection is not necessary per relevant international, regional, and

situation. Warn others near the cutting area of possible noise

local regulations.

hazards. In addition, ear protection can prevent hot splatter from

entering the ear.

Significant noise reduction can be obtained by adding simple

engineering controls to cutting tables such as barriers or curtains

positioned between the plasma arc and the workstation, and/or

locating the workstation away from the plasma arc. Implement

administrative controls in the workplace to restrict access and limit

operator exposure time, and screen off noisy areas and/or take

measures to reduce reverberation in cutting areas by putting up noise

absorbers.

DRY DUST COLLECTION INFORMATION

In some workplaces, dry dust can represent a potential explosion

Note 1 – Unless a site-specific evaluation has been completed that

hazard.

determines that none of the dust generated is combustible, then

NFPA standard 68 requires the use of explosion vents. Design the

The U.S. National Fire Protection Association’s NFPA standard 68,

explosion vent size and type to conform to the worst-case Kst value

“Explosion Protection by Deflagration Venting,” provides requirements

as described in Annex F of NFPA standard 68. NFPA standard 68

for the design, location, installation, maintenance, and use of devices

does not specifically identify plasma cutting or other thermal cutting

and systems to vent combustion gases and pressures after any

processes as requiring deflagration venting systems, but it does

deflagration event. Consult with the manufacturer or installer of any

apply these new requirements to all dry dust collection systems.

dry dust collection system for applicable requirements before you

install a new dry dust collection system or make significant changes

Note 2 – Users should consult and comply with all applicable

in the process or materials used with an existing dry dust collection

national, state, and local regulations. Publications do not intend to

system.

urge action that is not in compliance with all applicable regulations

and standards, and this manual may never be construed as doing so.

Consult your local “Authority Having Jurisdiction” (AHJ) to determine

whether any edition of NFPA standard 68 has been “adopted by

reference” in your local building codes.

Refer to NFPA standard 68 for definitions and explanations of

regulatory terms such as deflagration, AHJ, adopted by reference, the

Kst value, deflagration index, and other terms.

SC-10 Safety and Compliance

English

Safety

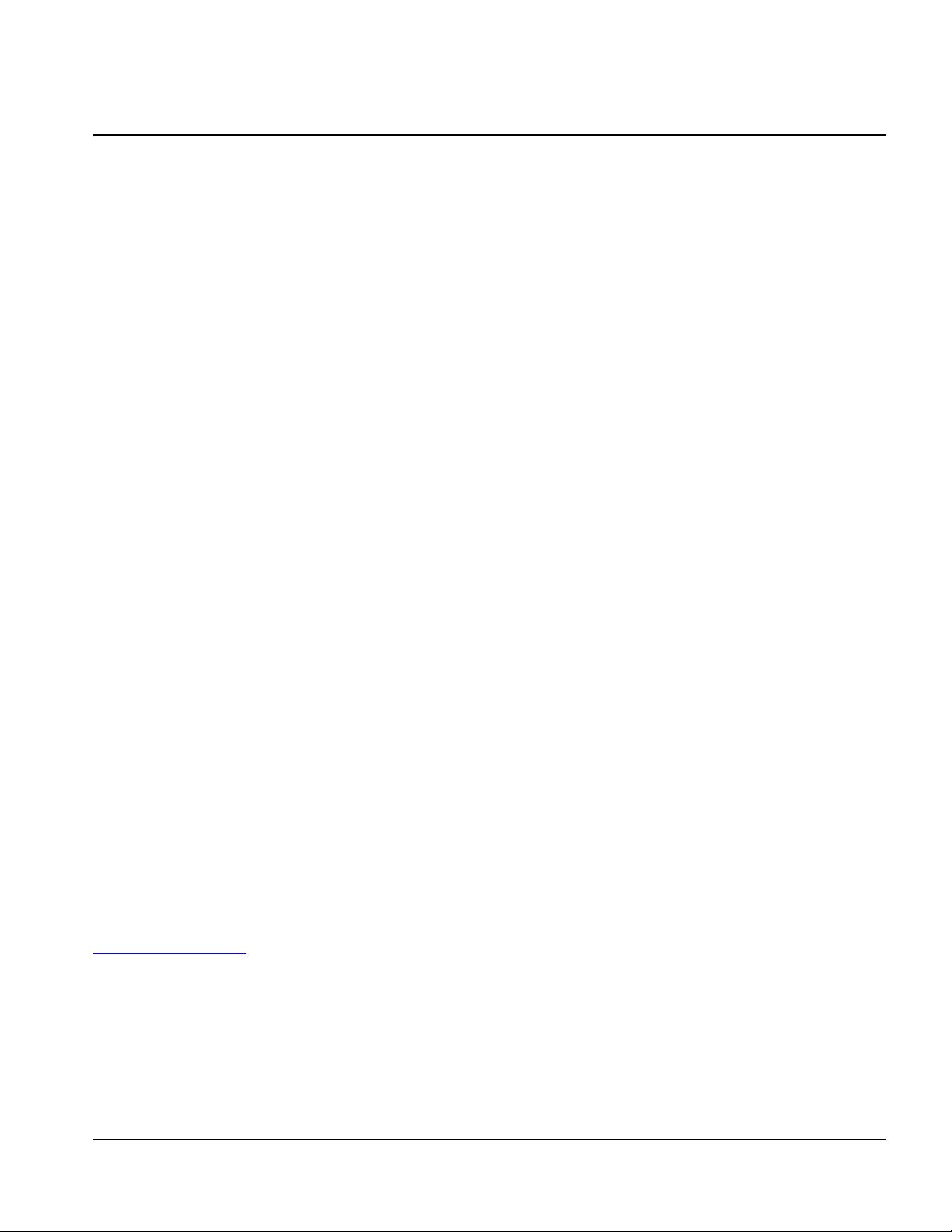

LASER RADIATION

Exposure to the laser beam from a laser pointer can result in serious eye injury. Avoid direct eye exposure.

On products that use a laser pointer for alignment, one of the following laser radiation labels has been applied on the product near where the laser

beam exits the enclosure. The maximum output (mV), wavelength emitted (nM), and, if appropriate, pulse duration are also provided.

Additional laser safety instructions:

• Modifying the laser or product in any way can increase the risk of

laser radiation.

• Consult with an expert on local laser regulations. Laser safety

training may be required.

• Use of adjustments or performance of procedures other than those

specified in this manual may result in hazardous laser radiation

• Do not allow untrained persons to operate the laser. Lasers can be

exposure.

dangerous in the hands of untrained users.

• Do not operate in explosive atmospheres, such as in the presence

• Do not look into the laser aperture or beam at any time.

of flammable liquids, gases, or dust.

• Position the laser as instructed to avoid unintentional eye contact.

• Use only laser parts and accessories that are recommended or

• Do not use the laser on reflective workpieces.

provided by the manufacturer for your model.

• Do not use optical tools to view or reflect the laser beam.

• Repairs and servicing must be performed by qualified personnel.

• Do not disassemble or remove the laser or aperture cover.

• Do not remove or deface the laser safety label.

ADDITIONAL SAFETY INFORMATION

1. ANSI Standard Z49.1, Safety in Welding and Cutting, American

6. CGA Pamphlet P-1, Safe Handling of Compressed Gases in

Welding Society, 550 LeJeune Road, P.O. Box 351020, Miami,

Cylinders, Compressed Gas Association, 1235 Jefferson Davis

FL 33135

Highway, Arlington, VA 22202

2. ANSI Standard Z49.2, Fire Prevention in the Use of Cutting and

7. CSA Standard W117.2, Code for Safety in Welding and

Welding Processes, American National Standards Institute,

Cutting, Canadian Standards Association Standard Sales,

1430 Broadway, New York, NY 10018

178 Rexdale Boulevard, Rexdale, Ontario M9W 1R3, Canada

3. ANSI Standard Z87.1, Safe Practices for Occupation and

8. NFPA Standard 51B, Cutting and Welding Processes, National

Educational Eye and Face Protection, American National

Fire Protection Association, 1 Batterymarch Park, Quincy, MA

Standards Institute, 1430 Broadway, New York, NY 10018

02169-7471

4. AWS F4.1, Recommended Safe Practices for the Preparation

9. NFPA Standard 70, National Electrical Code, National Fire

for Welding and Cutting of Containers and Piping That Have

Protection Association, 1 Batterymarch Park, Quincy, MA

Held Hazardous Substances, American Welding Society, 550

02169-7471

LeJeune Road, P.O. Box 351040, Miami, FL 33135

10. OSHA, Safety and Health Standards, 29FR 1910 U.S.

5. AWS F5.2, Recommended Safe Practices for Plasma Arc

Government Printing Office, Washington, D.C. 20402

Cutting, American Welding Society, 550 LeJeune Road,

11. AWS Safety and Health Fact Sheets, American Welding

P.O. Box 351040, Miami, FL 33135

Society, 550 LeJeune Road, P.O. Box 351040, Miami, FL

33135, www.aws.org/technical/facts/

Safety and Compliance SC-11

English

Safety

SC-12 Safety and Compliance

English

Product Stewardship

Introduction

Differences in national standards

Hypertherm maintains a global Regulatory Management System to

Nations may apply different performance, safety or other standards.

ensure that products comply with regulatory and environmental

National differences in standards include, but are not limited to:

requirements.

•Voltages

• Plug and cord ratings

National and local safety regulations

• Language requirements

• Electromagnetic compatibility requirements

National and Local safety regulations shall take precedence over any

instructions provided with the product. The product shall be imported,

These differences in national or other standards may make it impossible

installed, operated and disposed of in accordance with national and local

or impractical for all certification test marks to be placed on the same

regulations applicable to the installed site.

version of a product. For example, the CSA versions of Hypertherm’s

products do not comply with European EMC requirements, and therefore

Certification test marks

do not have a CE marking on the data plate.

Countries that require CE marking or have compulsory EMC regulations

Certified products are identified by one or more certification test marks

must use CE versions of Hypertherm products with the CE marking on

from accredited testing laboratories. The certification test marks are

the data plate. These include, but are not limited to:

located on or near the data plate.

•Australia

Each certification test mark means that the product and its safety-critical

• New Zealand

components conform to the relevant national safety standards as

reviewed and determined by that testing laboratory. Hypertherm places

• Countries in the European Union

a certification test mark on its products only after that product is

• Russia

manufactured with safety-critical components that have been authorized

by the accredited testing laboratory.

It is important that the product and its certification test mark be suitable

for the end-use installation site. When Hypertherm products are shipped

Once the product has left the Hypertherm factory, the certification test

to one country for export to another country; the product must be

marks are invalidated if any of the following occurs:

configured and certified properly for the end-use site.

• The product is modified in a manner that creates a hazard or

non-conformance with the applicable standards.

Safe installation and use of shape cutting

• Safety-critical components are replaced with unauthorized spare

equipment

parts.

• Any unauthorized assembly, or accessory that uses or generates a

IEC 60974-9, titled Arc Welding Equipment – Installation and use,

hazardous voltage is added.

provides guidance in the safe installation and use of shape cutting

• There is any tampering with a safety circuit or other feature that is

equipment and the safe performance of cutting operations. The

designed into the product as part of the certification, or otherwise.

requirements of national and local regulations shall be taken into

consideration during installation, including, but not limited to, grounding

CE marking constitutes a manufacturer’s declaration of conformity to

or protective earth connections, fuses, supply disconnecting device, and

applicable European directives and standards. Only those versions of

type of supply circuit. Read these instructions before installing the

Hypertherm products with a CE Marking located on or near the data

equipment. The first and most important step is the safety assessment of

plate have been tested for compliance with the European Low Voltage

the installation.

Directive and the European EMC Directive. EMC filters needed to

comply with the European EMC Directive are incorporated within

The safety assessment must be performed by an expert, and determines

versions of the power supply with a CE Marking.

what steps are necessary to create a safe environment, and what

precautions should be adopted during the actual installation and

Certificates of compliance for Hypertherm products are available from

operation.

the Downloads Library on the Hypertherm web site at

https://www.hypertherm.com

.

Procedures for periodic inspection and

testing

Where required by local national regulations, IEC 60974-4 specifies test

procedures for periodic inspection and after repair or maintenance, to

ensure electrical safety for plasma cutting power sources built in

conformity with IEC 60974-1. Hypertherm performs the continuity of the

protective circuit and insulation resistance tests in the factory as

non-operating tests. The tests are performed with the power and ground

connections removed.

Safety and Compliance SC-13

English

Product Stewardship

Hypertherm also removes some protective devices that would cause

Higher-level systems

false test results. Where required by local national regulations, a label

shall be attached to the equipment to indicate that it has passed the

When a system integrator adds additional equipment; such as cutting

tests prescribed by IEC 60974-4. The repair report shall indicate the

tables, motor drives, motion controllers or robots; to a Hypertherm

results of all tests unless an indication is made that a particular test has

plasma cutting system, the combined system may be considered a

not been performed.

higher-level system. A higher-level system with hazardous moving parts

may constitute industrial machinery or robotic equipment, in which case

the OEM or end-use customer may be subject to additional regulations

Qualification of test personnel

and standards than those relevant to the plasma cutting system as

manufactured by Hypertherm.

Electrical safety tests for shape cutting equipment can be hazardous and

shall be carried out by an expert in the field of electrical repair, preferably

It is the responsibility of the end-use customer and the OEM to perform a

someone also familiar with welding, cutting, and allied processes. The

risk assessment for the higher-level system, and to provide protection

safety risks to personnel and equipment, when unqualified personnel are

against hazardous moving parts. Unless the higher-level system is

performing these tests, may be much greater than the benefit of periodic

certified when the OEM incorporates Hypertherm products into it, the

inspection and testing.

installation also may be subject to approval by local authorities. Seek

advice from legal counsel and local regulatory experts if you are uncertain

Hypertherm recommends that only visual inspection be performed unless

about compliance.

the electrical safety tests are specifically required by local national

regulations in the country where the equipment is installed.

External interconnecting cables between component parts of the higher

level system must be suitable for contaminants and movement as

required by the final end use installation site. When the external

Residual current devices (RCDs)

interconnecting cables are subject to oil, dust, water, or other

In Australia and some other countries, local codes may require the use of

contaminants, hard usage ratings may be required.

a Residual Current Devices (RCD) when portable electrical equipment is

When external interconnecting cables are subject to continuous

used in the workplace or at construction sites to protect operators from

movement, constant flexing ratings may be required. It is the

electrical faults in the equipment. RCDs are designed to safely

responsibility of the end-use customer or the OEM to ensure the cables

disconnect the mains electrical supply when an imbalance is detected

are suitable for the application. Since there are differences in the ratings

between the supply and return current (there is a leakage current to

and costs that can be required by local regulations for higher level

earth). RCDs are available with both fixed and adjustable trip currents

systems, it is necessary to verify that any external interconnecting cables

between 6 to 40 milliamperes and a range of trip times up to

are suitable for the end-use installation site.

300 milliseconds selected for the equipment installation, application and

intended use. Where RCDs are used, the trip current and trip time on

RCDs should be selected or adjusted high enough to avoid nuisance

tripping during normal operation of the plasma cutting equipment and

low enough in the extremely unlikely event of an electrical fault in the

equipment to disconnect the supply before the leakage current under a

fault condition can pose a life threatening electrical hazard to operators.

To verify that the RCDs continue to function properly over time, both the

trip current and the trip time should be tested periodically. Portable

electrical equipment and RCDs used in commercial and industrial areas

in Australia and New Zealand are tested to the Australian standard

AS/NZS 3760. When you test the insulation of plasma cutting

equipment to AS/NZS 3760, measure the insulation resistance

according to Appendix B of the standard, at 250 VDC with the power

switch in the ON position to verify proper testing and to avoid the false

failure of the leakage current test. False failures are possible because the

metal oxide varistors (MOVs) and electromagnetic compatibility (EMC)

filters, used to reduce emissions and protect the equipment from power

surges, may conduct up to 10 milliamperes leakage current to earth

under normal conditions.

If you have any questions regarding the application or interpretation of

any IEC standards described here, you are required to consult with an

appropriate legal or other advisor familiar with the International

Electrotechnical standards, and shall not rely on Hypertherm in any

respect regarding the interpretation or application of such standards.

SC-14 Safety and Compliance

English

Environmental Stewardship

Introduction

• In the United States, check all federal, state, and local laws.

• In the European Union, check the EU directives, national, and local

The Hypertherm Environmental Specification requires RoHS, WEEE and

laws. For more information, visit www.hypertherm.com/weee

.

REACH substance information to be provided by Hypertherm’s

• In other countries, check national and local laws.

suppliers.

• Consult with legal or other compliance experts when appropriate.

Product environmental compliance does not address the indoor air

quality or environmental release of fumes by the end user. Any materials

The WEEE Directive

that are cut by the end user are not provided by Hypertherm with the

product. The end user is responsible for the materials being cut as well

On January 27, 2003, the European Parliament and the Council of the

as for safety and air quality in the workplace. The end user must be aware

European Union authorized Directive 2002/96/EC or WEEE (Waste

of the potential health risks of the fumes released from the materials

Electrical and Electronic Equipment).

being cut and comply with all local regulations.

As required by the legislation, any Hypertherm product covered by the

directive and sold in the EU after August 13, 2005 is marked with the

National and local environmental

WEEE symbol. This directive encourages and sets specific criteria for

regulations

the collection, handling, and recycling of EEE waste. Consumer and

business-to-business wastes are treated differently (all Hypertherm

National and local environmental regulations shall take precedence over

products are considered business-to-business). Disposal instructions for

any instructions contained in this manual.

the CE versions of Powermax plasma systems can be found at

www.hypertherm.com/weee

.

The product shall be imported, installed, operated and disposed of in

accordance with all national and local environmental regulations

The URL is printed on the symbol-only warning label for each of these

applicable to the installed site.

CE version Powermax series units shipped since 2006. The CSA

versions of Powermax and other products manufactured by Hypertherm

The European Environmental regulations are discussed later in

are either out of scope or exempt from WEEE.

The WEEE Directive.

The REACH regulation

The RoHS directive

The REACH regulation (1907/2006), in force since June1, 2007, has an

Hypertherm is committed to complying with all applicable laws and

impact on chemicals available to the European market. The REACH

regulations, including the European Union Restriction of Hazardous

regulation requirements for component manufacturers states that the

Substances (RoHS) Directive that restricts the use of hazardous

component shall not contain more than 0.1% by weight of the

materials in electronics products. Hypertherm exceeds RoHS Directive

Substances of Very High Concern (SVHC).

compliance obligations on a global basis.

Component manufacturers and other downstream users, such as

Hypertherm continues to work toward the reduction of RoHS materials in

Hypertherm, are obligated to obtain assurances from its suppliers that all

our products, which are subject to the RoHS Directive, except where it is

chemicals used in or on Hypertherm products will have a European

widely recognized that there is no feasible alternative.

Chemical Agency (ECHA) registration number. To provide chemical

information as required by the REACH regulation, Hypertherm requires

Declarations of RoHS Conformity have been prepared for the current

suppliers to provide REACH declarations and identify any known use of

CE versions of Powermax plasma cutting systems manufactured by

REACH SVHC. Any use of SVHC in amounts exceeding 0.1% w/w of

Hypertherm. There is also a “RoHS mark” on the Powermax CE versions

the parts has been eliminated. The MSDS contains a full disclosure of all

below the “CE Marking” on the data plate of CE versions of Powermax

substances in the chemical and can be used to verify REACH SVHC

series units shipped since 2006. Parts used in CSA versions of

compliance.

Powermax and other products manufactured by Hypertherm that are

either out of scope or exempt from RoHS are continuously being

The lubricants, sealants, coolants, adhesives, solvents, coatings and

converted to RoHS compliance in anticipation of future requirements.

other preparations or mixtures used by Hypertherm in, on, for, or with its

shape cutting equipment are used in very small quantities (except the

Proper disposal of Hypertherm products

coolant) and are commercially available with multiple sources that can

and will be replaced in the event of a supplier problem associated with

Hypertherm plasma cutting systems, like all electronic products, may

REACH Registration or REACH Authorization (SVHCs).

contain materials or components, such as printed circuit boards, that

cannot be discarded with ordinary waste. It is your responsibility to

dispose of any Hypertherm product or component part in an

environmentally acceptable manner according to national and local

codes.

Safety and Compliance SC-15

English

Environmental Stewardship

Proper handling and safe use of chemicals

Chemical Regulations in the USA, Europe, and other locations require

that Material Safety Data Sheets (MSDS) be made available for all

chemicals. The list of chemicals is provided by Hypertherm. The MSDS

are for chemicals provided with the product and other chemicals used in

or on the product. MSDS can be downloaded from the Downloads

Library on the Hypertherm web site at https://www.hypertherm.com

.

On the Search screen, insert MSDS in the document title and click on

Search.

In the USA, OSHA does not require Material Safety Data Sheets for

articles such as electrodes, swirl rings, retaining caps, nozzles, shields,

deflectors and other solid parts of the torch.

Hypertherm does not manufacture or provide the materials that are cut

and has no knowledge whether the fumes released from materials that

are cut will pose a physical hazard or health risk. Please consult with your

supplier or other technical advisor if you need guidance concerning the

properties of the material you will cut using a Hypertherm product.

Fumes emission and air quality

Note: The following information on air quality is intended for general

information only and should not be used as a substitute for reviewing and

implementing applicable government regulations or legal standards in

the country where the cutting equipment will be installed and operated.

In the USA, the National Institute for Occupational Safety and Health

(NIOSH) Manual of Analytical Methods (NMAM) is a collection of

methods for sampling and analyzing contaminants in workplace air.

Methods published by others, such as OSHA, MSHA, EPA, ASTM, ISO

or commercial suppliers of sampling and analytical equipment, may have

advantages over NIOSH methods.

For example, ASTM Practice D 4185 is a standard practice for the

collection, dissolution, and determination of trace metals in workplace

atmospheres. The sensitivity, detection limit, and optimum working

concentrations for 23 metals are listed in ASTM D 4185. An industrial

hygienist should be used to determine the optimum sampling protocol,

considering analytical accuracy, cost, and optimum sample number.

Hypertherm uses a third party industrial hygienist to perform and interpret

air quality testing results taken by air sampling equipment positioned at

operator stations in Hypertherm buildings where plasma cutting tables

are installed and operated.

Where applicable, Hypertherm also uses a third party industrial hygienist

to obtain air and water permits.

If you are not fully aware and up to date on all applicable government

regulations and legal standards for the installation site, you should

consult a local expert prior to purchasing, installing, and operating the

equipment.

SC-16 Safety and Compliance

English