Partner B305 CBS Rev.7: instruction

Class: Gardening equipment

Type:

Manual for Partner B305 CBS Rev.7

B305 CBS

INSTRUCTION MANUAL

IMPORTANT INFORMATION

: Please read these instructions carefully and make

GB

sure you understand them before using this unit. Retain these instructions for future

reference.

ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ

ВАЖНАЯ ИНФОРМАЦИЯ:

Пожалуйста, внимательно прочтите данную

RU

инструкцию перед тем, как приступить к зксппуатации триммера, и убедитесь что

она вам понятна. Сохраните инструкцию для дальнейшего обращения к ней.

ANVÄNDARHANDBOK

VIKTIG INFORMATION

: Läs dessa anvisningar noggrant och se till att du förstår

SE

dem innan du använder trimmeren och spara dem för framtida behov.

BRUKERHÅNDBOK

NO

VIKTIG INFORMASJON:

Vennligst les disse instruksjonene nøye og pass på at De

forstår dem før De bruker trimmeren og oppbevar den for senere bruk.

BRUGERHÅNDBOG

VIGTIGE OPLYSNINGER:

Læs venligst disse instruktioner omhyggeligt og vær

DK

sikker på, at De forstår dem, før De anvender græstrimmeren og gemme til senere

henvisning.

KÄYTTÖOHJEKIRJA

FI

TÄRKEÄÄ:

Lue tämä ohjekirja huolellisesti läpi ennen kuin alat käyttää laitetta.

Säilytä ohjekirja myöhempää käyttöä varten.

INSTRUKCJA OBSŁUGI

WAZNE INFORMACJE:

Przed rozpoczęciem użytkowania urządzenia, należy

PL

uważnie przeczytać i zrozumieć ninijszą instrukcją. Instrukcje należy przechowywać

do późniejszego z niej korzystania.

NÁVOD K POUŽĺVÁNĺ

CS

DŮLEŽITÁ INFORMACE:

Prosíme, než začnete zařízení používat, přečtěte si

pečlivě tyto pokyny a ujistěte se, že jim plně rozumíte.

ПОСІБНИК З ЕКСПЛУАТАЦІЇ

ВАЖЛИВА ІНФОРМАЦІЯ.

Уважно прочитайте інструкції та переконайтеся, що

UA

Ви їх зрозуміли, перш ніж використовувати пристрій. Зберігайте ці інструкції для

подальшого використання.

576191709 Rev. 7 07/22/14

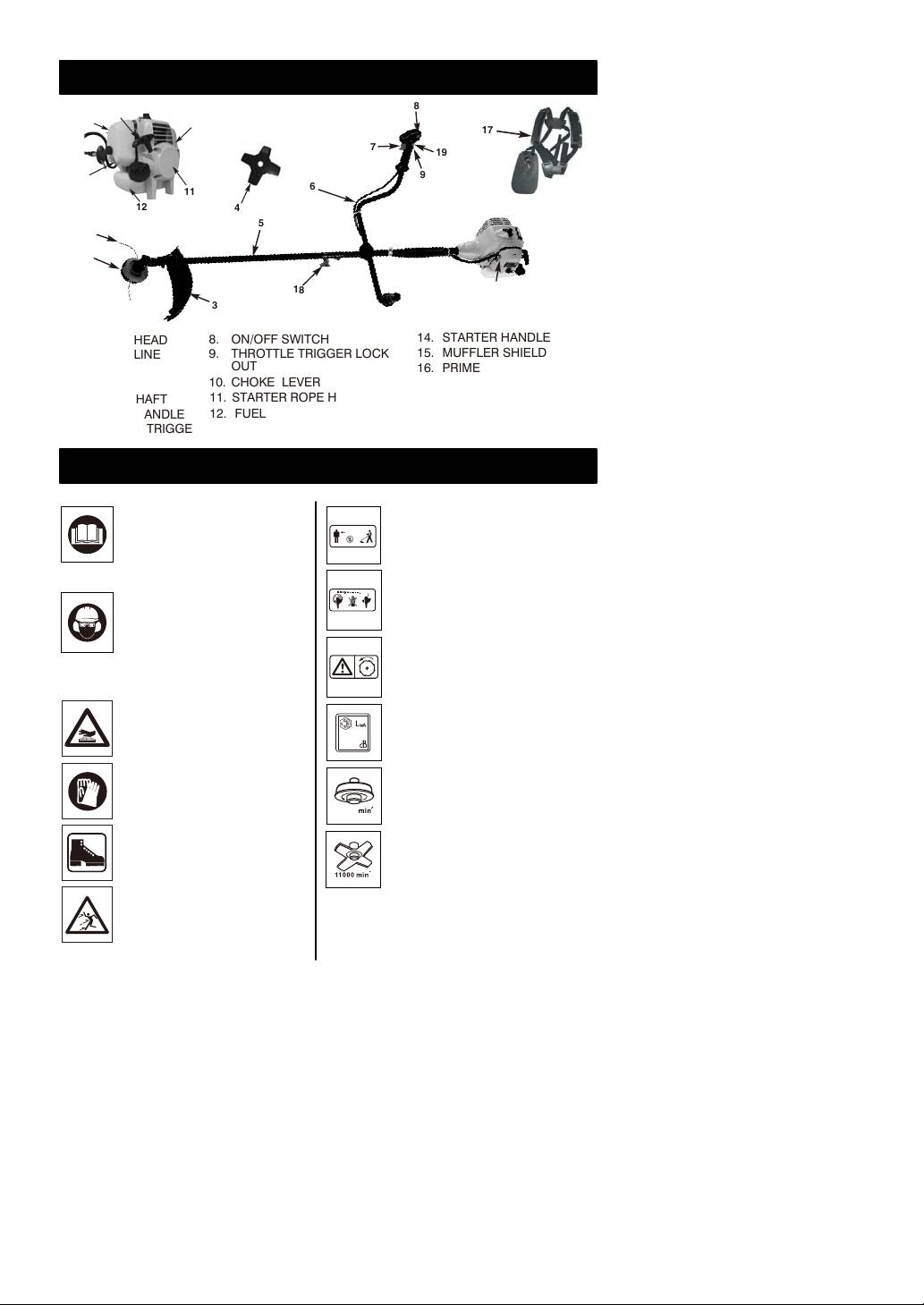

IDENTIFICATION (WHAT IS WHAT?)

17

4

1. TRIMMER HEAD

8. ON/OFF SWITCH

14. STARTER HANDLE

2. TRIMMER LINE

9. THROTTLE TRIGGER LOCK

15. MUFFLER SHIELD

3. SHIELD

OUT

16. PRIMER BULB

4. BLADE

10. CHOKE LEVER

17. SHOULDER HARNESS

5. OUTPUT SHAFT

11. STARTER ROPE HOUSING

18. COUPLER

6. “Bullhorn” HANDLE

12. FUEL TANK

19. THROTTLE LOCK

7. THROTTLE TRIGGER

13. AIR FILTER COVER

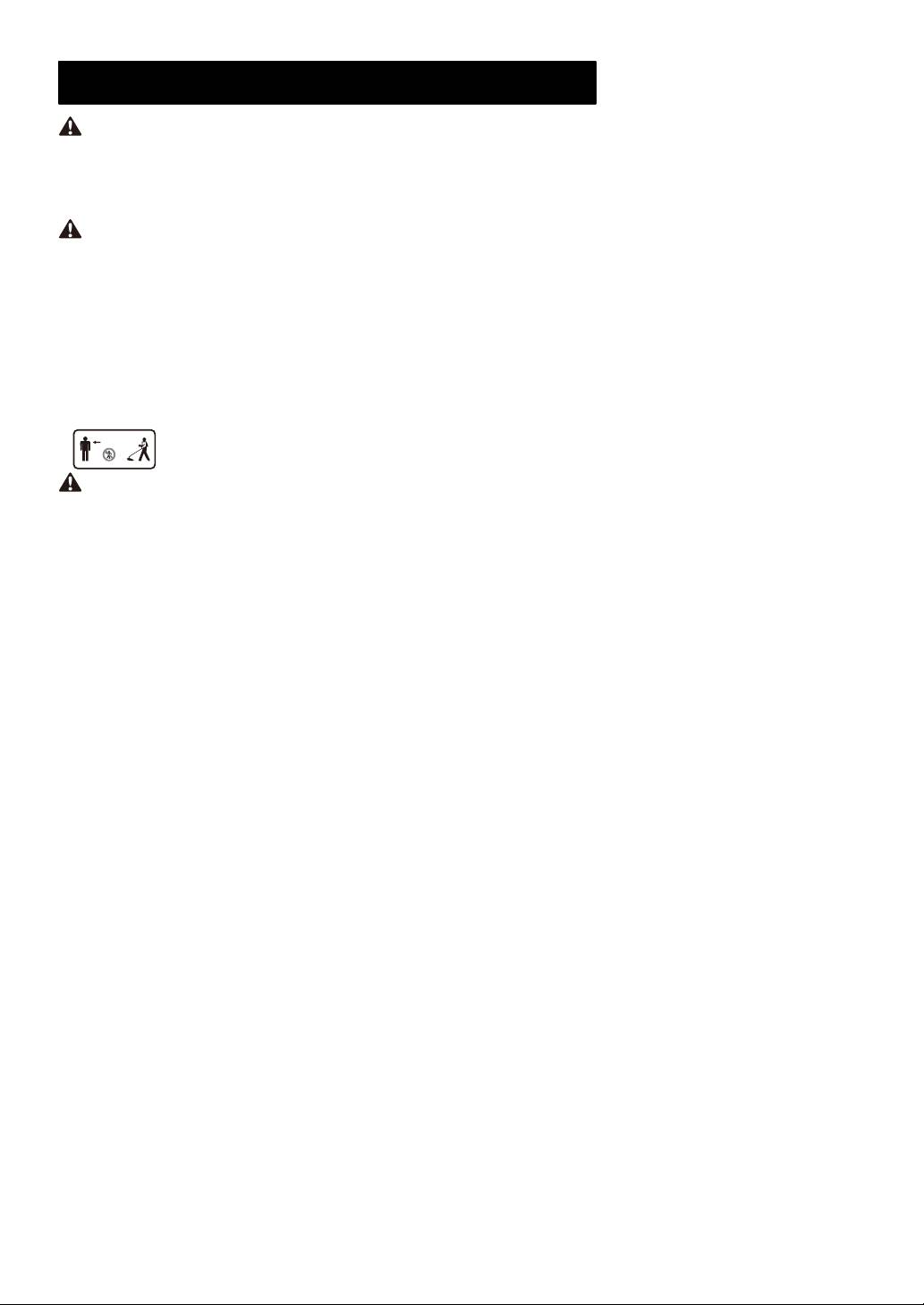

IDENTIFICATION OF SYMBOLS

Read and understand the Instr-

Keep people or animals at least

uction Manual and all warning

15m away from the machine

labels before using the machine.

during operation

Whenever the machine is in use,

WARNING: Cutting elem-

safety glasses must be worn to

safeguard against flying objects.

ents continue to rotate after the

Ear protection must also be used

engine turned off

in order to protect to operators

hearing. If the operator is

working in an area where there is

WARNING:

a risk of falling objects a safety

helmet must also be worn.

Rotating blades

Guaranteed sound power level

WARNING: Hot surface.

LWA accordance with directive

2000/14/EC + 2005/88/EC

Wear gloves to protect

your hands

Wear foot protection

Beware of thrown objects

-- 2 --

15m(50ft)

112

8

14

13

15

7

19

16

9

6

11

12

5

2

1

18

10

3

Maximum rotational frequency of

the spindle for cutting head

13300

Maximum rotational frequency of

the spindle for blade

SAFETY RULES

WARNING: When using gas tools,

• Check area you will be trimming for

basic safety precautions, including the

debris that may be struck or thrown

following, should always be followed to

during operation.

reduce the risk of serious personal injury

• Keep all parts of your body and

and/or damage to the unit. Read all these

clothing away from trimmer head when

instructions before operating this product

starting or running engine. Before starting

and save these instructions.

engine, make sure trimmer head will not

come in contact with any obstacle.

WARNING: This machine produces

• Stop engine before examining cutting

an electromagnetic field during operation.

line.

This field may under some circumstances

• Store equipment away from possible

interfere with active or passive medical

ignition sources ,such as gas-powered

implants. To reduce the risk of serious or

water heaters, clothes dryers, or oil-fired

fatal injury, we recommend persons with

furnaces, portableheaters, etc.

medical implants to consult their physician

• Aways keep the debris shield, trimmer

and the medical implant manufacturer

head, and engine free of debris build-up.

before operating this machine.

• Operation of equipment should always

be restricted to mature and properly

WHAT TO DO

instructed individuals.

READ YOUR USER MANUAL AND ALL

• WARNING: The emission of exhaust

SUPPLEMENTS (IF ANY ENCLOSED)

gases is toxic.

THOROUGHLY BEFORE OPERATING

• Emergency Stopping Procedure.When it

YOUR UNIT.

is necessary to stop engine immediately,

15m(50ft)

DEPRESS the switch to stop.

• This unit has a clutch. The routine for

checking that the clutch is working

correctly is that when the engine returns to

WARNING: Keep children, bystan-

idle the trimmer head stops spinning.

ders, and animals 50 feet (15 meters) away.

• Tighten the cap of oil and fuel tank to

If approached stop unit immediately.

prevent the loss of oil and fuel during

• Wear close fitting,tough work clothing

transport.

that will provide protection, such as long

• It is recommended that daily inspection

slacks or trousers, safety work shoes,

before use and after dropping or other

heavy duty work gloves, hard hat, a safety

impacts to prevent significant damage or

face shield, or safety glasses for eye

defects.

protection and a good grade of ear plugs

• Prolonged use of this product expose the

or other sound barriers for hearing

operator to vibrations and may produce

protection.

‘whitefinger’ disease. In order to reduce

• Prefuel in a safe place. Open fuel cap

the risk, please wear gloves and keep

slowly to release any pressure which may

your hands warm. If any of the

have formed in fuel tank. To prevent a fire

‘whitefinger’ symptoms appear, seek

hazard, move at least 10 feet (3 meters)

medical advice immediately.

from fueling area before starting.

BRUSH / GRASS BLADE SAFETY

• Comply with all fire prevention

PRECAUTIONS

regulations. Your unit comes with a spark

• FOLLOW ALL WARNINGS and

arrester screen furnished in the user

instructions regarding operation and blade

kit.Replacement spark arrester screen kits

installation.

are available from distributor.

• BLADE CAN VIOLENTLY THRUST

• Turn unit off before setting it down.

AWAY FROM MATERIAL IT CANNOT

• Always hold unit firmly with both

CUT - Blade thrust can cause

hands, the thumb and fingers encircling

amputation of arms or legs. Keep

the handles.

people and animals 50 feet (15 meters)

• Keep all screws and fasteners tight.

away in all directions. If blade contacts

Never operate your equipment when it is

foreign objects during operation, turn off

improperly adjusted or not completely and

engine and allow coasting blade to stop.

securely assembled.

Then check blade for damage. Always

• Keep handles dry, clean and free of fuel

discard blade if it is warped or cracked.

mixture.

• BLADE THROWS OBJECTS VIOLE-

• Keep trimmer head as close to ground

NTLY - You can be blinded or injured.

as practical. Avoid hitting small objects

Wear eye, face, and leg protection.

with trimmer head. When cutting on a

Always clear work area of any foreign

slope, stand below trimmer head. NEVER

objects before using blade. Keep people

cut or trim on a hill or slope, etc. If there is

and animals 50 feet (15 meters) away in

the slightest chance of slipping, sliding or

all directions.

losing firm footing.

-- 3 --

Table of contents

- IDENTIFICATION (WHAT IS WHAT?)

- SAFETY RULES

- ASSEMBLY

- FUEL AND LUBRICATION

- TRIMMER INSTRUCTIONS

- OPERATING INSTRUCTIONS FOR USE WITH BLADE

- MAINTENANCE INSTRUCTIONS

- DECLARATION OF CONFORMITY

- TECHNICAL DATA SHEET

- ОПИСАНИЕ ДЕТАЛЕЙ ИНСТРУМЕНТА

- ПРАВИЛА ТЕХНИКИ БЕЗОПАСНОСТИ

- СБОРКА

- ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

- IDENTIFIERING (VAD ÄR VAD?)

- SÄKERHETSREGLER

- MONTERING

- DRIFTSINSTRUKTIONER

- TEKNISKT DATABLAD

- IDENTIFIKASJON (HVA ER HVA?)

- SIKKERHETSREGLER

- ASSEMBLY

- INSTRUKSJONER FOR BRUK

- TEKNISKE DATA

- IDENTIFICERING (HVAD ER HVAD?)

- SIKKERHEDSREGLER

- SAMLING

- DRIFTSANVISNINGER

- TEKNISK DATAARK

- TUNNISTUS (MIKÄ ON OLEELLISTA?)

- TURVAOHJEET

- KOKOAMINEN

- KÄYTTÖOHJEET

- TEKNISET TIEDOT

- IDENTYFIKACJA (CO TO JEST?)

- ZASADY BEZPIECZEŃSTWA

- СБОРКА

- ARKUSZ DANYCH TECHNICZNYCH

- IDENTIFIKACE (CO JE CO?)

- BEZPEČNOSTNÍ PRAVIDLA

- MONTÁŽ

- TECHNICKÉ ÚDAJE

- ІДЕНТИФІКАЦІЯ (ЩО ЦЕ ТАКЕ?)

- ПРАВИЛА ТЕХНІКИ БЕЗПЕКИ

- ЗБИРАННЯ

- ТЕХНІЧНИЙ ПАСПОРТ