Alexika RET control-visc – page 2

Manual for Alexika RET control-visc

21

>100 mm

>100 mm

>100 mm

Safety instructions

•

Please read the instruction manual in full before use and

follow the safety instructions.

• Keep the instruction manual in a place where it can be accessed

easily.

General instructions

•

Ensure that only trained staff use the device.

•

Be sure to comply with all safety instructions, directives and all

matters of health, safety and accident prevention in the workplace.

• The plug must be earthed (grounded contact).

Caution - magnetism!

Beware of possible effects from the

magnetic field (pacemakers, data media,

etc.).

Burns hazard!

Exercise caution when touching housing

components and the heating plate. The

heating plate can reach temperatures of up to 320°C. Watch for

residual heat after appliance has been switched off.

The device should only be transported once it has cooled!

Device configuration

Do

not

operate the device in explosive

atmospheres, in the presence of hazard-

ous materials or under water.

• Install the device on a flat, stable, clean, non-slip, dry and fire-

resistant surface.

• The device feet must be clean and undamaged.

• The power supply cable and cables to the external sensors must

not be allowed to come into contact with the heated mounting

plate.

• Prior to each use, always check the device and accessories for

damage. Never use damaged parts.

Permissible media / Contamination / Side reactions

Caution!

Only media whose flashpoint

lies above the set safety temperature

limit (50°C - 380°C) may be processed

or heated with this device.

The set safety temperature limit must be at least 25°C below the

flashpoint of the medium in use.

Pay attention to the risks associated

with:

- flammable materials

- flammable media with low steam pressure

- glass breakage

- incorrect vessel size

- overfilling of medium

- unstable vessel.

• Only process pathogenic materials in closed vessels under a suit

-

able extractor hood. Please contact

IKA

®

if you have any ques-

tions.

Only work with media for which the en-

ergy input during processing is harmless.

This also needs to take into account

other sources of energy such as, for example, light irradiation.

• At high speeds the mounting plate is liable to warming, even if

the device is not in heating mode.

• Bear in mind the possibility of contamination or unwanted chem

-

ical reactions.

• There is the possibility that friction from rotating accessory parts

can result in contamination of the medium being processed.

• Bear in mind the following when using PTFE-coated magnetic

rods:

Chemical reactions of PTFE occur in contact with molten

or solute alkali metals and alkaline earth metals as well as with

fine powders of metals in groups 2 and 3 of the periodic table

ATTENTION

DANGER

at temperatures above 300-400°C. Only elementary fluorine,

chlorine trifluoride and alkali metals attack it; halogenated hy-

drocarbons have a reversible swelling effect

.

(Source: Römpp “Chemie-Lexikon” and “Ullmann” Vol. 19)

• Only glass-coated magnetic rods should be used in conjunction

with solute alkali metals or alkaline earth metals or at tempera-

tures above 250°C.

Performing trials

Always

wear personal protective

equipment in accordance with the hazard

class of the media being worked with.

Otherwise there is the risk of the following:

- spraying and evaporation of liquids

- ejection of parts

- release of toxic or inflammable gases.

• If any of the following happens, reduce the speed:

- medium sprays out of vessel due to excessive speed

- process is not smooth

- vessel moves around on the mounting plate.

Accessories

• Safe operation can only be ensured when working with acces

-

sories as described in the “

Accessories

” section.

• Only put together accessories with the power supply cable dis

-

connected.

• Refer to the operating instructions for the accessories.

• Immerse the external temperature sensor (PT1000, ETS-D, etc.)

at least 20 mm into the medium.

• The PT1000 external temperature sensor must always be inside

the medium.

• Accessories must be connected securely to the device and must

not come loose on their own. The centre of gravity of the device

must be located within the mounting plate.

Power supply / switching off the device

• The specified settings on the rating plate must coincide with the

actual power supply.

• The plug for the power supply connection must be easy to access

and remove.

• The device is only disconnected from the power supply when the

power or device plug is removed.

After an interruption to the power sup-

ply, the device starts up again in Mode B.

Protection of the device

• The device must only be opened by trained, skilled personnel.

• Do not cover the device, even partially, with elements such as

metallic plates or sheets otherwise it may overheat.

• Avoid knocks or impact to the device or accessories.

• Ensure the mounting plate remains clean.

•

Observe minimum distances between devices, between the device

and the wall, and above and below the device (min. 800 mm).

WARNING

DANGER

WARNING

WARNING

DANGER

WARNING

22

Unpacking

• Unpacking

- Unpack the device carefully

- Any damage should be notified immediately to the shipping

agent (post office, railway network or transport company)

• Scope of delivery

- RET control visc heated magnetic stirrer

- Power supply cable

- Operating instructions

- Screwdriver (safety circuit)

- USB cable

- Protective cover:

H104

- Magnetic rods:

IKAFLON

30

and

40

mm

- Temperature sensor:

PT 100.70

Correct use

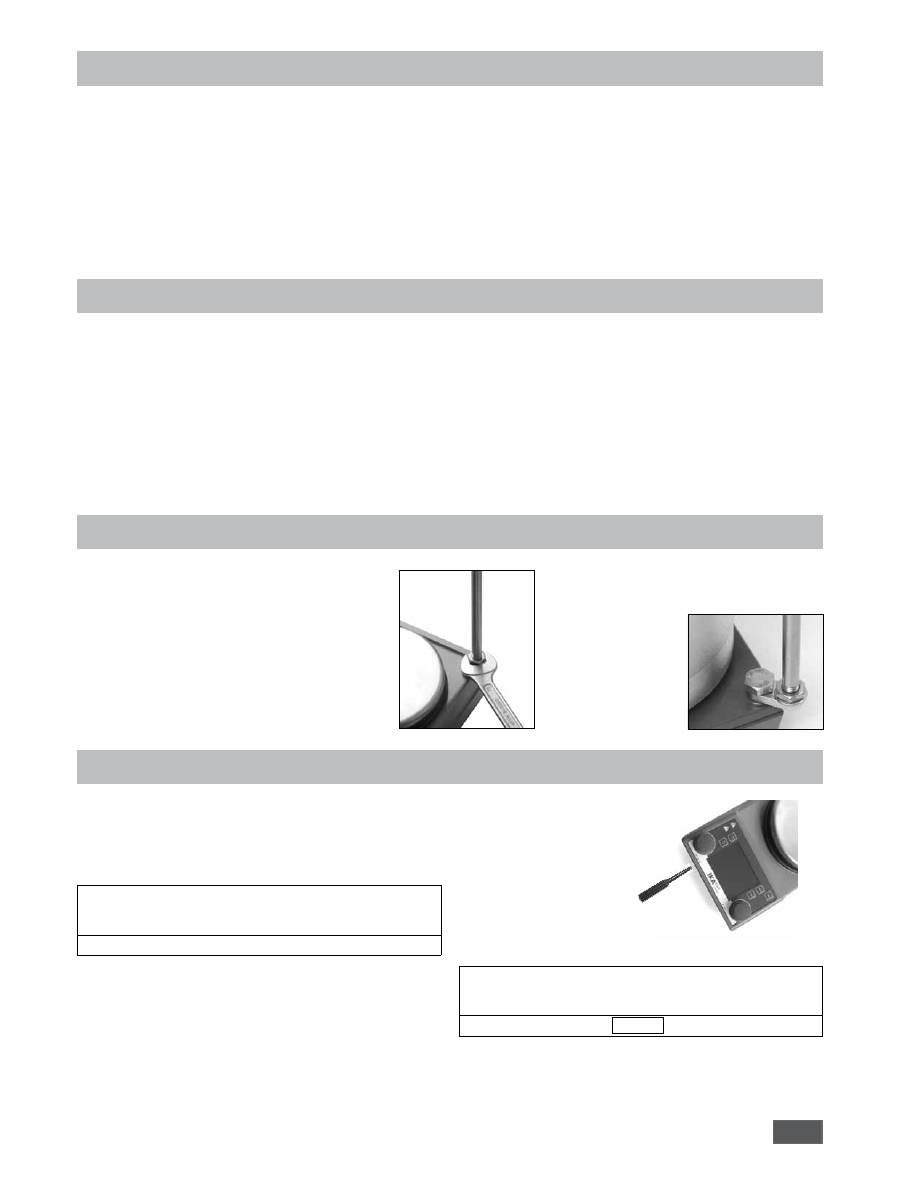

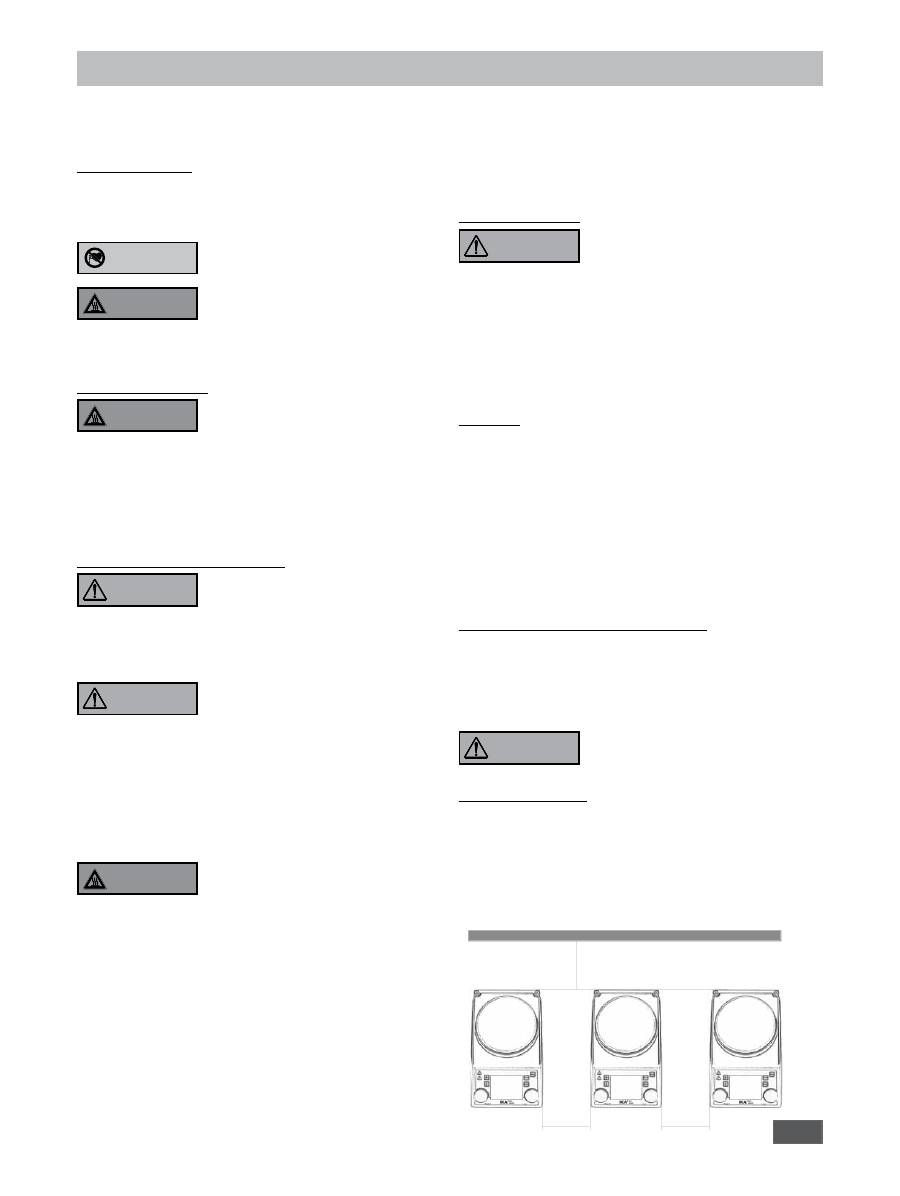

Assembling the support rod

Note:

When using bath attachments with a diameter

over 180 mm, use sup-

port rod H 16 V in con-

junction with an H

16.1 extension.

The set safety temperature is displayed permanently (

7

).

Factory settings: approx. 380°C

Range: 50 - 380°C

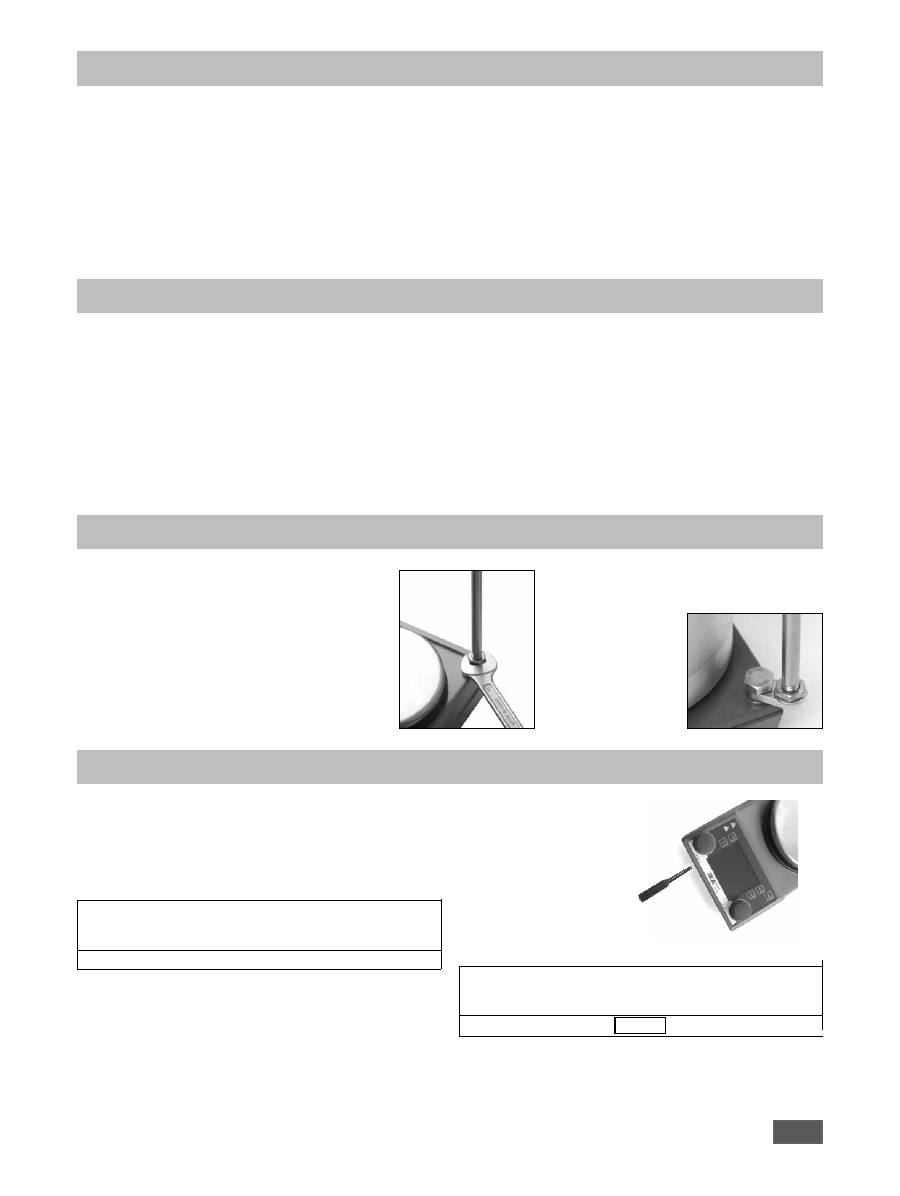

Setting the safety temperature limit

a

Set the main switch

(A)

to the ON position

a

Set the temperature limit using the screwdriver (supplied)

at point

(B)

i

The set value is displayed on the screen

The adjustable maximum heating plate temperature of 340°C is

at least 10°C under the set safety temperature limit.

Caution: the set safety temperature limit must always be

at least 25°C below the flashpoint of the medium in use.

Functional test: safety circuit switch-off

a

Heat the device to a temperature of over 50°C.

a

Set the safety temperature limit as far to the left as possible (50°C)

and set the main switch (A) to the ON position

i

The display will show: Err 25

Setting the safety temperature limit

Be careful not to turn the adjustment screw too far to the left or

right or this will damage the potentiometer.

• Use

- for mixing and/or heating liquids.

• Area of use (only indoors)

- laboratories

- schools

- pharmacies

- universities

The device is suitable for use in all areas apart from domestic areas

and areas directly connected to a low-voltage supply which also

serves domestic areas.

The safety of the user cannot be guaranteed if the device is used

in conjunction with accessories which are not supplied or recom-

mended by the manufacturer, if the device is used contrary to the

intended purpose against the manufacturer’s instructions or if the

device itself or PCB has been subjected to modifications by third

parties.

•

Remove the threaded plug

(P)

• Remove the protective cap from the support rod

• Place the washer between the housing and the nut

• Screw in the support rod manually until it cannot be

tightened further

• Tighten the nut using an SW17 open-end spanner

• Assemble the accessories using a boss head clamp

23

Remove the protective film from the mounting plate before use! The “Back” menu key is used to change between menu items.

Start-up

Stirring

Heating

Connecting an ex-

ternal thermometer

(directtemperature

control in the me-

dium)

Weighing

pH measurement

Timer

F

Set the main switch (A) to the OFF position

F

Insert the power supply cable into the mains socket (K)

F

Set the main switch (A) to the ON position

a

Standard mode A is selected (see “Operating modes”)

F

Set the speed using the rotary knob (D)

a

The set value is shown on the display (F)

F

Press the rotary knob (D) to start the stirring function

i

a

The symbol (16) appears when the motor is active

F

Set the safety temperature limit (see “Setting the safety temperature limit”)

F

Set the target temperature using the rotary knob (C)

a

The set value is shown on the display (J)

F

Set the temperature control mode (see “Setting the temperature control mode”)

F

Press the rotary knob (C) to start the heating function

The target and current temperature are shown permanently on the display (J):

i

a

When the heating function is switched on, the heating symbol (4) is displayed

The maximum adjustable heating plate temperature setting is 340°C

i

a

Whenever the mounting plate is at a temperature above 50°C, the display (J) shows and the current tem-

perature is shown, even if the device is switched off.

F

Set the main switch (A) to the OFF position

F

Connect the safety contact thermometer compliant with DIN 12878 Class 2 or temperature sensor PT 100 (individual

sensor) or PT1000 (double sensor) to socket (L)

F

Set the main switch (A) to the ON position

i

Temperature sensor PT 100

a

The current temperature (5) shown on the display (J) corresponds to the tempera-

ture of the medium. The “Probe” symbol (11) lights up.

i

Temperature sensor PT 1000

a

The current temperature (5) for the temperature sensor shown on the display (J)

corresponds to the temperature of the medium. The “External temperature probe”

symbol (11) appears. The temperature of the carrier fluid (3) is also displayed.

F

Press the (G) key

F

Wait until the system is stable (once the system is stable, a “g” appears after the digit 0).

F

Place the weight in the centre of the heating plate and wait until the system is stable once again.

i

a

The maximum display range is up to 2,000 g

a

The weighing range is max. 5,000 g

a

It is only possible to use the weighing mode when the heating or stirring functions are not active

i

a

The weighing module can be calibrated (see section entitled “Calibrating the weighing module”)

a

see section entitled “Calibration of the pH probe and pH measurement”

F

Press the (H) key

F

Set the time in hours, minutes and seconds by turning the knob (D) and confirm by pressing it; the timer function

starts to count down the remaining time once the heating or stirring function has started (see “Timer function”)

i

Once the timer reaches 0, the heating function is switched off, even if the motor has only just been started.

If the heating is activated during the timer sequence, only the heating is switched off, but the motor continues

to run (delay in boiling).

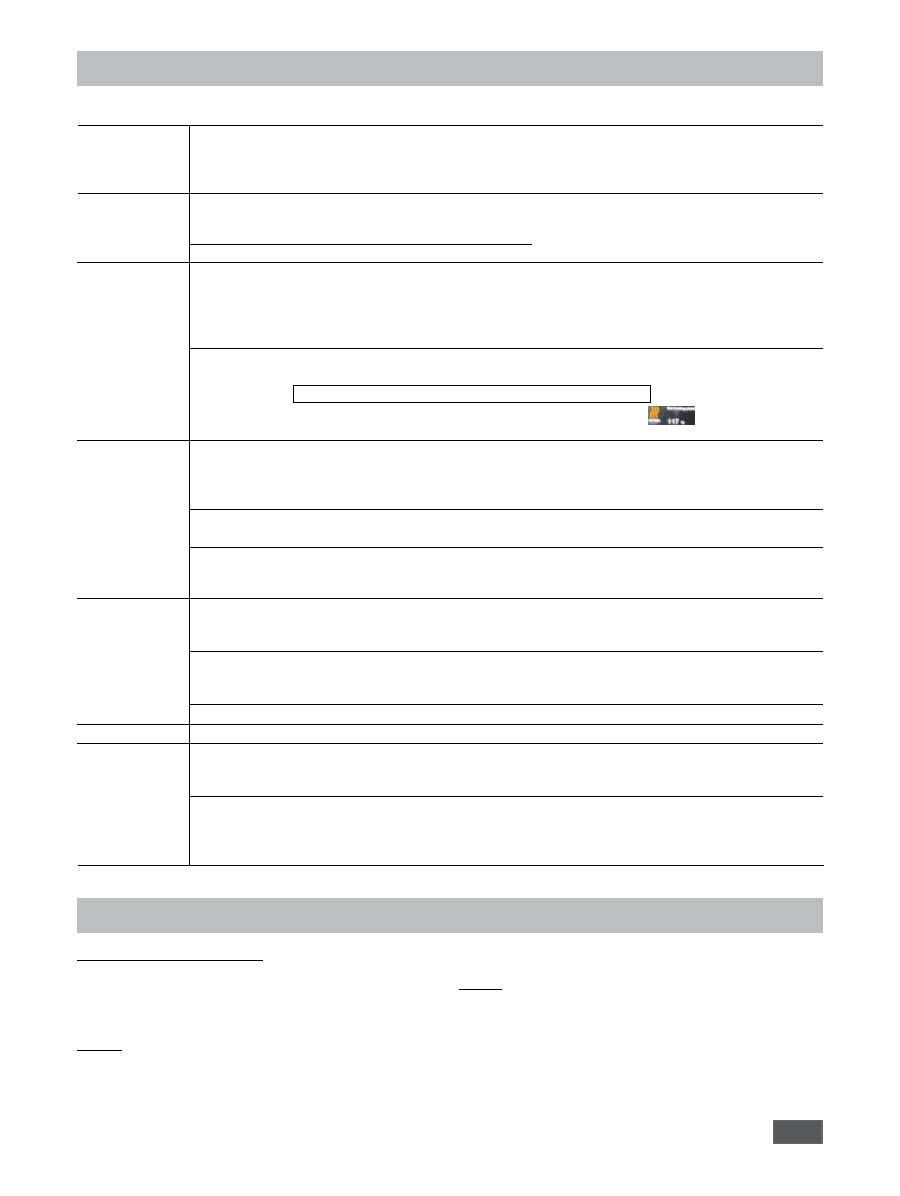

Operation

(brief instructions)

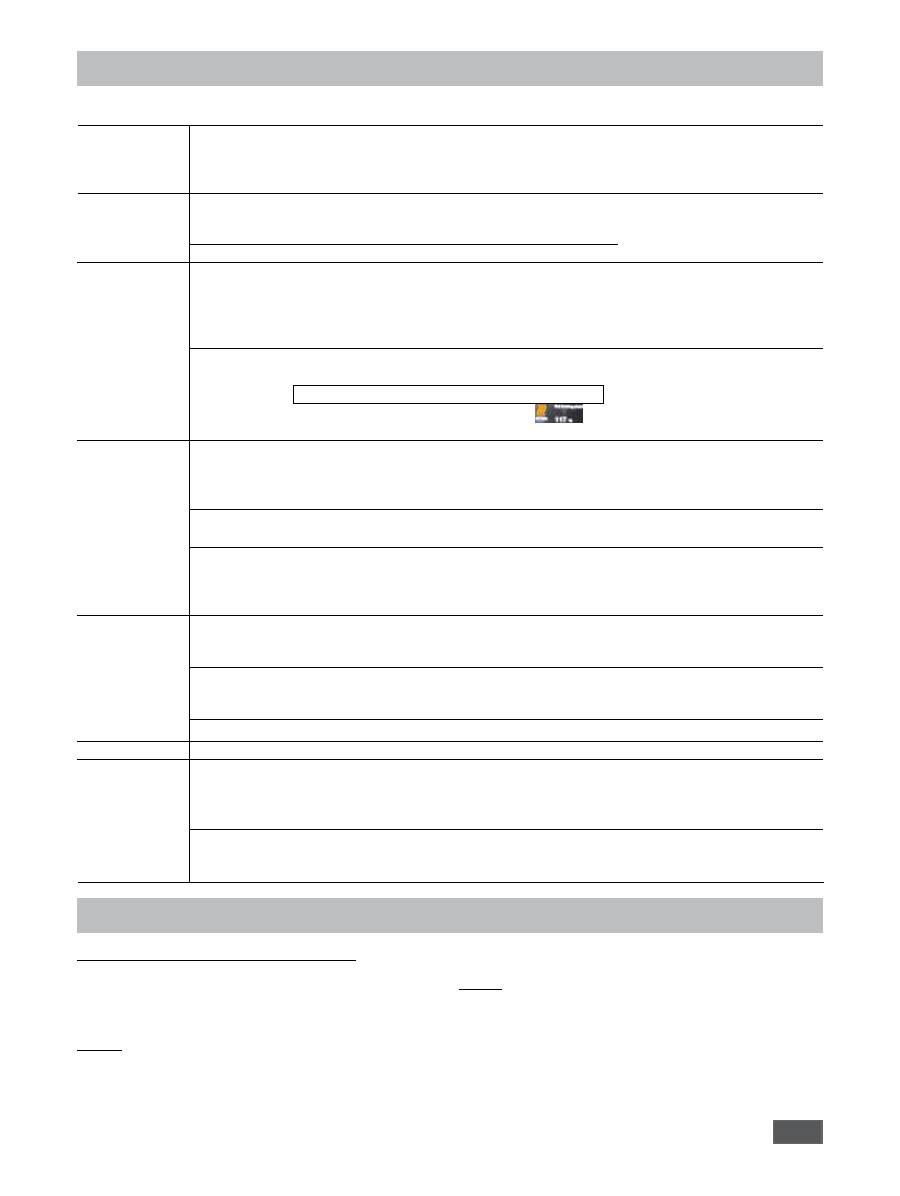

Setting the operating mode

Operating the device in A, B, or C

Factory setting: Mode A

The set mode is shown permanently on the display (10).

Mode A

All the settings are retained when the device is switched off or

disconnected from the mains. When the device is switched on,

the status of the stirring and heating functions is set to (OFF).

Mode B

All the settings are retained when the device is switched off or

disconnected from the mains. When the device is switched on,

the status of the stirring and heating functions is set to whatever

it was before the device was last switched off (ON or OFF).

24

Mode C

In this mode, the device can be used either with or without a

temperature sensor.

When the device is switched on using the main switch, the

stirring and heating functions are started in the last set status

and at the last set values. The set nominal values in operating

modes A and B cannot be modified.

Changing the operating mode

-

Scroll down to the “Mode” icon in the menu

-

Open the submenu by pressing the rotary knob (D)

-

Use the rotary knob (D) to select the desired mode and

confirm by pressing the rotary knob (D)

-

A short description of the operating mode is then shown

on the display

-

Confirm selection of the operating mode by pressing the

rotary knob (D) once more.

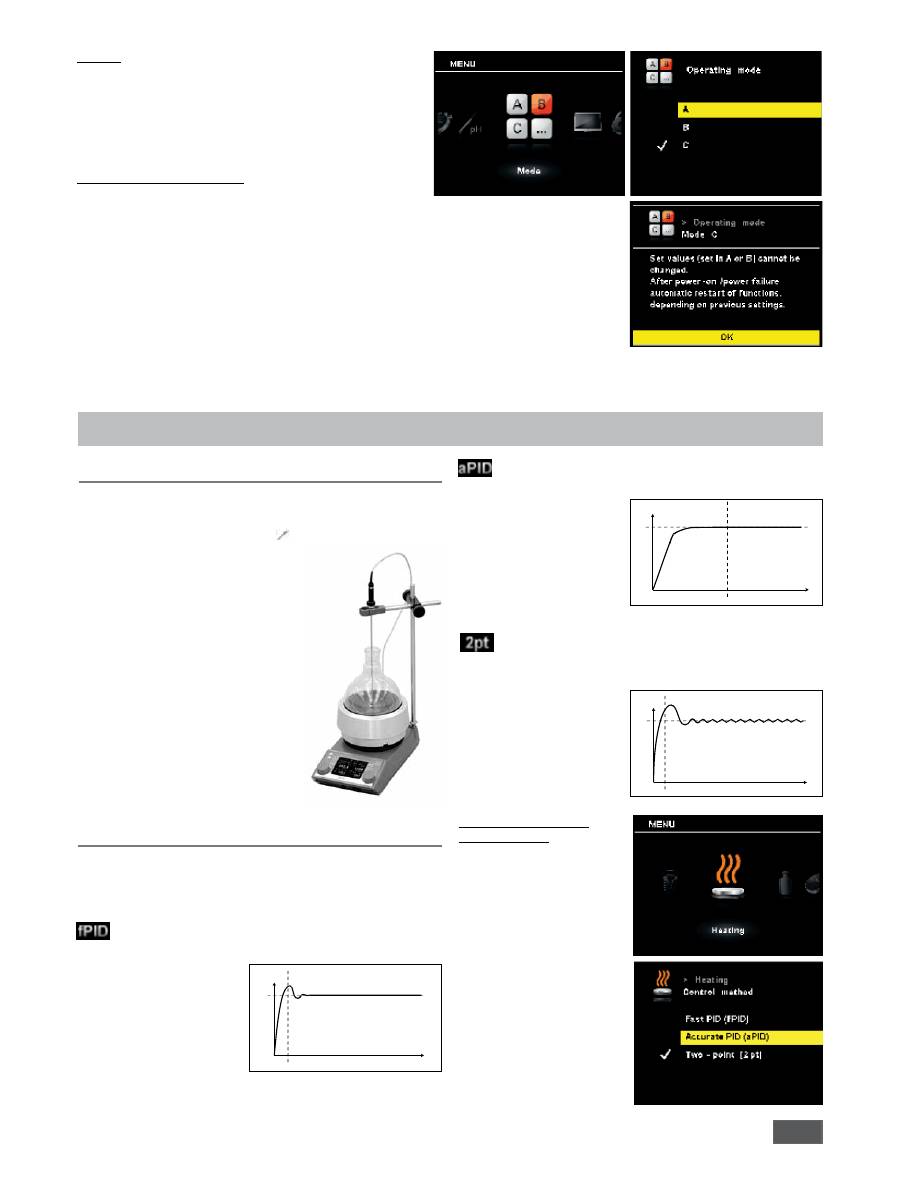

Functions

When using the PT100, the selected temperature control mode is

shown on the digital display by the

(11) symbol.

The target temperature (2) and the

current temperature (5) shown on

the display refer to the temperature

of the medium. The heating plate

temperature is limited by the set

safety temperature (7). The medium

temperature is controlled by means

of a microcontroller. The medium

temperature is measured by the PT100

temperature sensor and is heated

up as quickly as possible without

overshooting to the set temperature.

The microcontroller is capable of

adjusting automatically to the different

heating capacities of various vessels

and their contents. As a result, the heat

is distributed in an optimum fashion

with no temperature drift or ripples.

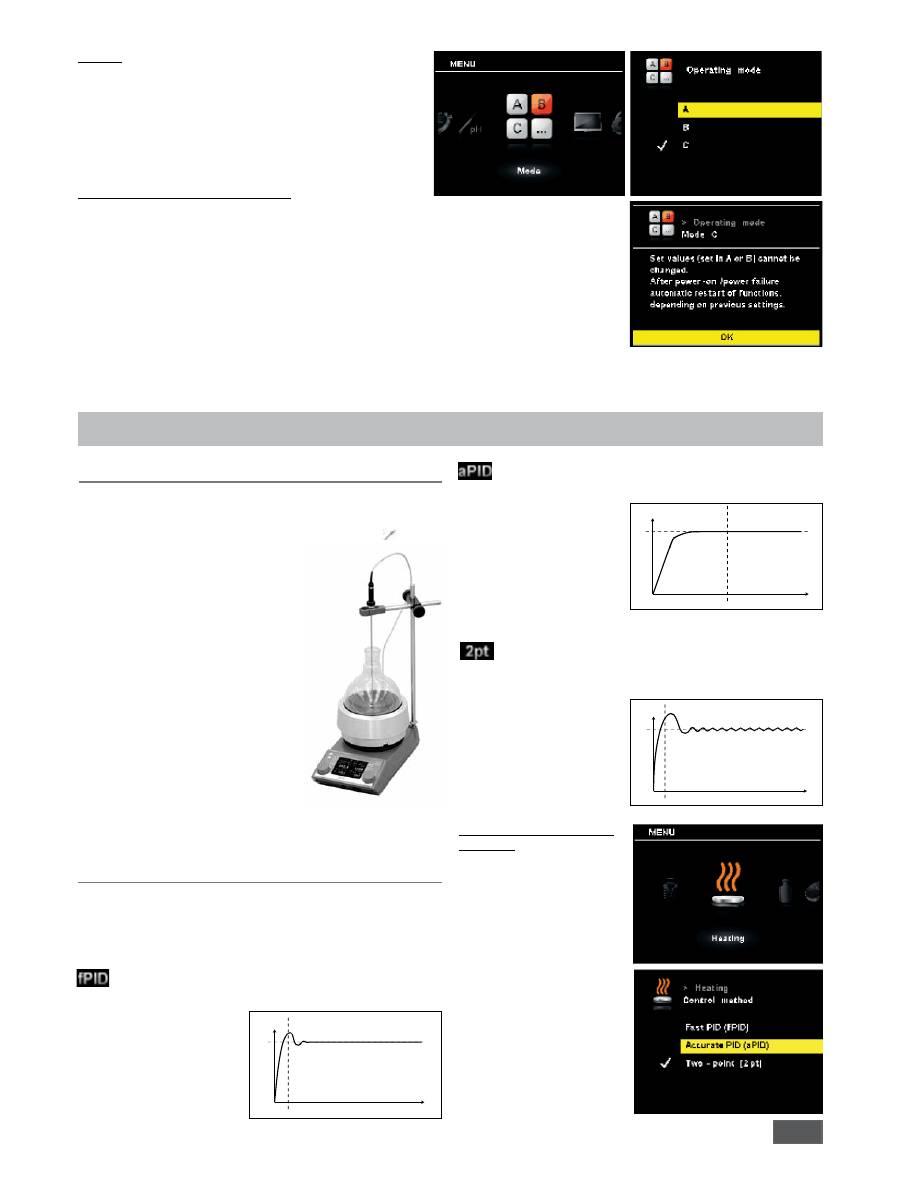

Regulation of the temperature of the medium

using PT100 temperature sensor

The user is able to set the device to three different methods

depending on their specific needs. The selected temperature

control method is displayed alongside the symbol (

11

).

Control methods

Changing between the

control methods

-

Scroll down to the

“Heating” icon in the menu

-

Open the control method

submenu by pressing the

rotary knob (D)

-

Use the rotary knob (D) to

select the desired mode

and confirm by pressing

the rotary knob (D)

-

A short description of the

operating mode is then

shown on the display

-

Confirm selection by

pressing the rotary knob (D)

once more.

PID

: For use with very sensitive materials which need to be

handled carefully.

Advantages:

• very accurate warming

of the liquid

• no exceeding the target

temperature

Disadvantages:

• slow heating operating

T

Set

t

Fast PID:

combines the advantages of the PID and two-point

methods (very fast

heating and high

accuracy; possible

overheating).

Two-point

:

For media which is not too sensitive.

Advantages:

• Heating much more

rapid than

PID

Disadvantages:

• Possible overheating of

up to 10 K

T

Set

t

T

Set

t

25

Operation with the PT1000 double

sensor is indicated on the digital

display by the

symbol. One

temperature sensor is located in the

heat carrier fluid and the other is

located in the reaction medium. The

set target temperature (2) refers to

the temperature of the medium. The

higher temperature is automatically

attributed to the heat carrier fluid and

shown on the display as an additional

current temperature with the symbol

(3).

The actual temperature of the reaction

medium is shown as the current

temperature (5). The heating plate

temperature (and therefore the heat

carrier fluid temperature) are limited by the set heating plate

safety temperature limit (7). The reaction medium temperature

is limited by the set temperature limits (carrier fluid/reaction

temperature limit).

see section entitled “Limits”

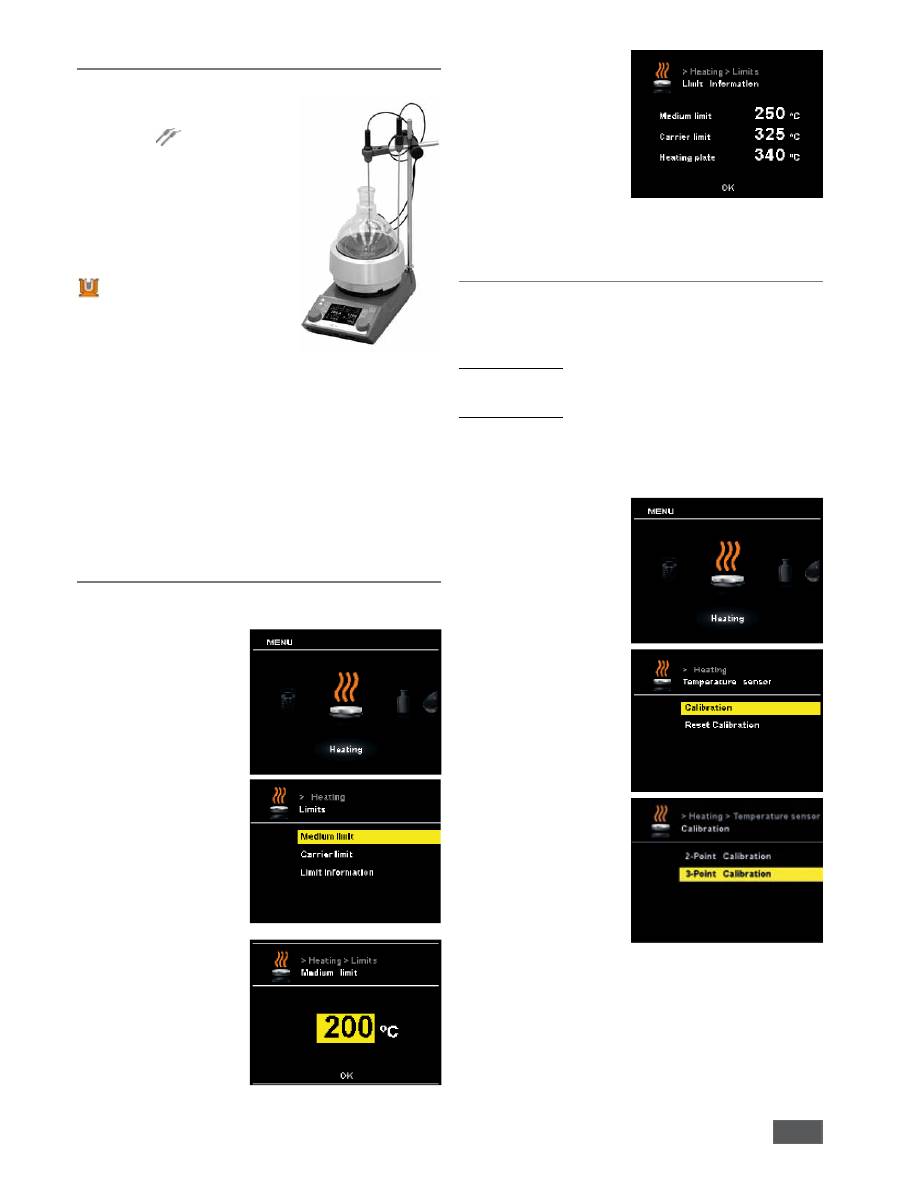

Limits

In order to ensure that neither the reaction fluid nor the carrier

fluid overheat, the user can set separate temperature limits.

• Scroll to the “Heating” icon

in the menu

• Open the submenu by

pressing the rotary knob (D)

• Open the “Limits” submenu

followed by “Medium

limit” and then set the

temperature limit for the

reaction fluid.

• Confirm the set limit by

pressing the rotary knob (D)

• Open the “Carrier limit”

submenu and set the limit

temperature for the carrier

fluid.

• Confirm the set limit by

pressing the rotary knob (D)

Regulation of the temperature of the medium

using PT1000 double temperature sensor

• Open the “Limit

information” submenu.

All set limit temperatures,

including the safety limit

temperature of the heating

plate, as displayed on one

screen.

• Close the submenu by

pressing the rotary knob (D)

Calibrating the temperature sensor

In order to use tolerances to limit temperature deviations, the

user can calibrate the temperature sensor in conjunction with the

device.

2-point calibration:

Calibration using two temperatures

3-point calibration:

Most accurate way of calibrating the temperature sensor at three

different temperatures

Note:

A calibration carried out by the user is indicated on the display

with the symbol (11) shown in

red

.The calibration of the PT100

and PT1000.50 double

sensor are carried out

separately.

• Scroll to the “Heating” icon

in the menu

• Open the submenu by

pressing the rotary knob (D)

• Open the “Temperature

sensor” submenu and

then “Calibration”, finally

confirming by pressing the

rotary knob (D)

• Select either 2-point

calibration or 3-point

calibration and confirm by

pressing the rotary knob (D)

In this function, the speed can be pre-set before starting the

calibration.

26

g

g

Stirring bar breakaway

If the device detects that a stirring bar has broken away, the

stirring function is interrupted temporarily in order to pick up

the bar. The system then returns to the previously set speed.

When the system detects a bar breakaway, this is indicated with

a special symbol (

instead of symbol 16). If another stirring

bar breakaway occurs within the next 3 minutes (as long as the

target speed has not been modified), once the bar is recovered

the system only goes up to a speed of 100 rpm. In the case of

4 consecutive stirring bar breakaways -with less than 3 minutes’

normal speed between them - the error message ER 41 is

displayed. The speed is reduced to 200 rpm and the heating is

switched off.

In such cases, the testing conditions will need to be reconsidered.

NOTE:

The user is responsible for ensuring the suitability/function

of the stirring bar breakaway monitoring for the current

conditions: stirring bar, speed, vessel, medium, etc.

Stirring bar breakaway monitoring does not work if the

stirring bar already breaks away before the system has

reached the set target speed!

The higher the torque to be transferred, the more safely the

stirring bar breakaway monitoring works.

In a glass beaker with water, the stirring bar breakaway for a

bar from 40 mm (d=8 mm) upwards can be seen from 300 -

1,200 rpm. Longer stirring bars, larger bar surface areas, e.g.

Trika, or higher speeds increase the torque to be transferred.

• Scroll to the “Stirring” icon

in the menu

• Open the submenu by

pressing the rotary knob (D)

• Open the “Stirring bar

breakaway” submenu and

confirm by pressing the

rotary knob (D)

• Acknowledge the informa

-

tion screen displayed by

pressing the rotary knob (D)

g

Intermittent mode

Intermittent mode consists of regular, cyclical interruption of

the stirring function. The run time and interval can both be set.

When switching on the device, the time for each is displayed if

intermittent mode is activated

• Scroll to the “Stirring” icon

in the menu

• Open the submenu by

pressing the rotary knob (D)

• Open the “Interval”

submenu and confirm by

pressing the rotary knob (D)

• Enter the run time and stop

time using the rotary knob

(D) and finally confirm the

two by pressing it again.

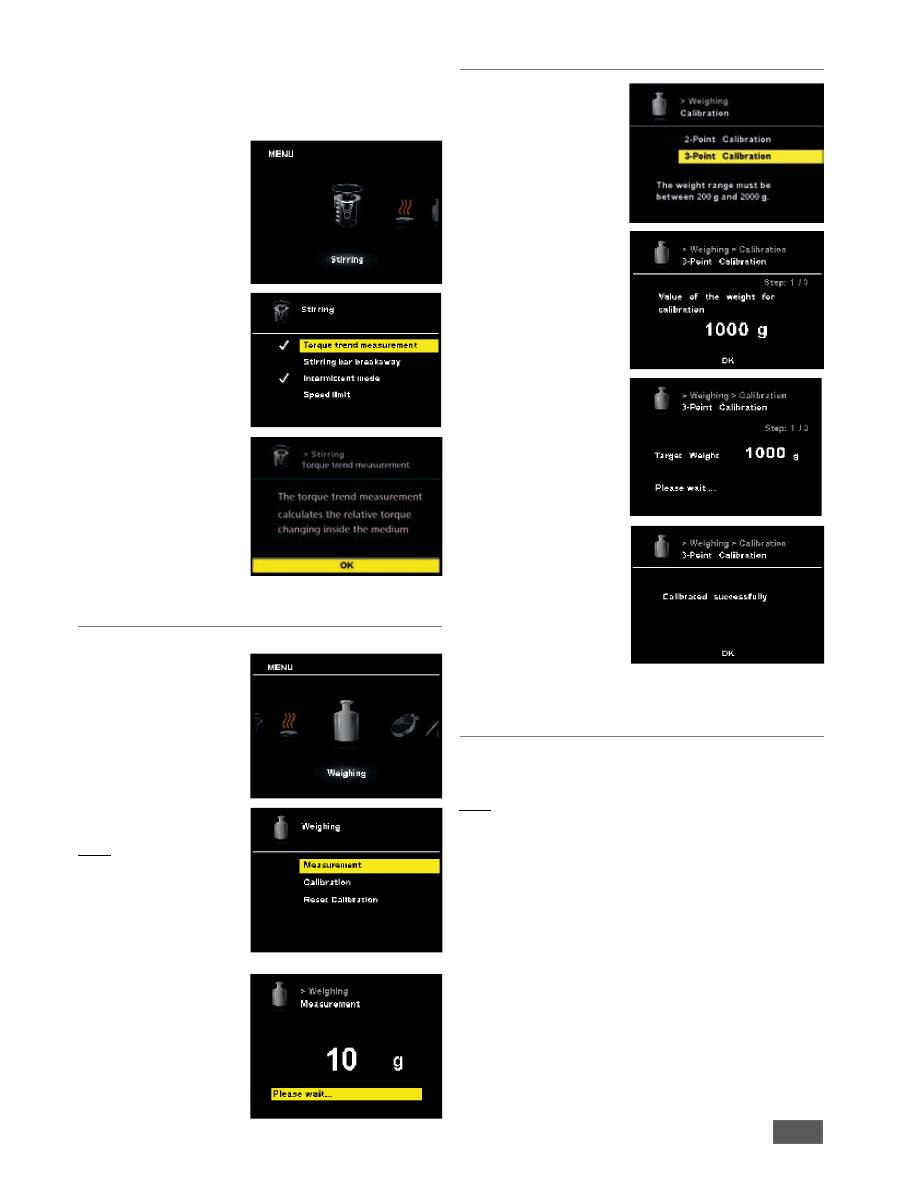

Torque trend measurement

The torque trend measurement is used to deduce the change in

viscosity of the reaction medium.

The devices are

not

designed to measure absolute viscosity. They

only measure and display the relative change in the viscosity of the

medium from a starting point specified by the user.

Once the speed of the motor and magnetic rod in the medium

have stabilised to the target speed, the viscosity measurement is

started at 100%.

Consequently, an increase in the measured torque trend is indicated

by a value > 100% and a reduction in values < 100%.

The value can always be reset to 100% by pressing the “Back” (F)

membrane key.

Note:

Torque trend measurement only works for a constant set

speed for the duration of the measurement.

As a result, intermittent mode cannot be used in

conjunction with torque trend measurement.

27

The current control variable is saved as the reference 100% ΔP

and shown on the digital display. The change in the viscosity is

then shown in %. Depending on whether the viscosity increases

or decreases, the percentage rises or falls above or below 100%

respectively.

• Scroll to the “Stirring” icon

in the menu

• Open the submenu by

pressing the rotary knob

(D)

• Open the “Torque trend

measurement” submenu

and confirm by pressing

the rotary knob (D)

• Acknowledge the informa

-

tion screen displayed

Weighing module

The weighing module is a function which allows the user to

perform simple weighing

tasks.

•

To start the weighing pro-

cess, press the (G) button

on the front membrane or

alternatively select Weig-

hing from the menu. Press

the rotary knob (D) to start

the weighing function.

Note:

The heating and stirring

functions must be deacti-

vated.

•

It may take several

moments for the system to

stabilise.

Once the system is stable,

a “g” will be shown

alongside the measured

value.

Weighing - Calibration

• Open the “Calibration”

submenu and confirm by

pressing the rotary knob

(D)

• Enter the calibration

weight and confirm by

pressing the rotary knob

(D)

• Place the calibration

weight on the mounting

plate and wait until the

device indicates that the

calibration process has

been completed.

This process needs to be

repeated two or three

times before closing cali-

bration mode

Once the calibration

process has been

completed successfully, the

weighing module is ready

for use.

Regularly re-calibrate the

device.

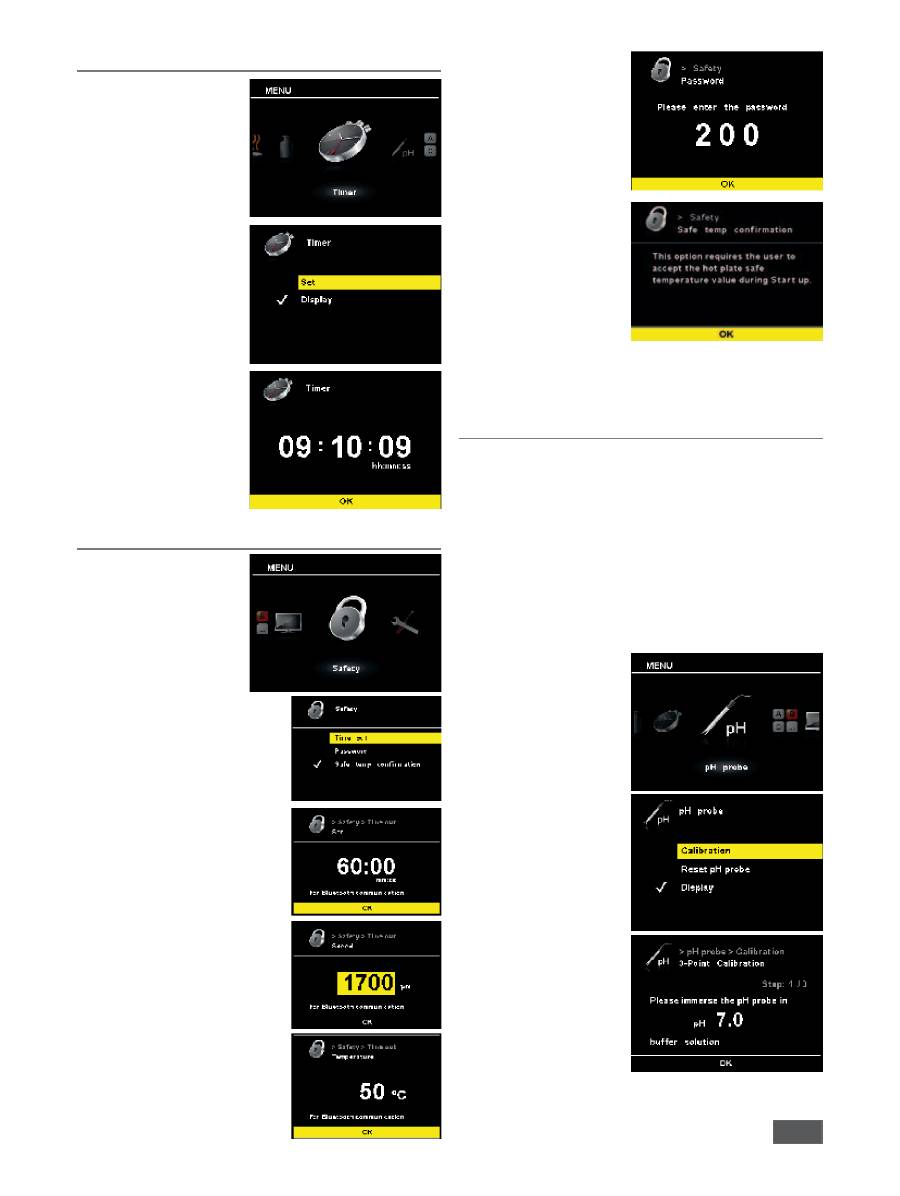

Timer / Counter

The Timer function allows the user to stop the heating process

after a certain time has lapsed. The Timer function can be set for

up to 99 hours, 59 minutes and 59 seconds.

Note:

The time starts to count down when starting both functions

(heating and/or stirring).

Once the heating function is activated, the timer function only

refers to heating. The stirring function continues to operate as

previously, thereby avoiding a delay in boiling in the liquid. The

motor is only switched off when the heating function is not

active. The stirring function is stopped if the heating function is

not started during the timer cycle and the time runs out.

NOTE:

By entering a value of

00:00:00

(hh:mm:ss), the counter is

activated. The counter shows the time elapsed during the current

experiment.

28

Setting of the timer

•

To start the timer function,

press the (H) button on

the front membrane or

alternatively select “Timer”

from the submenu.

The timer settings are

opened by clicking on

“Set”. The timer can be set

by turning the rotary knob

(D).

• Set the hours and press the

rotary knob (D)

• Set the minutes and press

the rotary knob (D)

• Set the seconds and press

the rotary knob (D)

The selected timer (count-

down) time is shown on

the display.

Safety settings

The user has several options

in the safety settings menu,

and the device functions can

be set according to the user’s

individual requirements.

•

To start, select “Safety” in

the submenu and confirm

by pressing the rotary knob

(D).

The “Timer” function is used to

define how long an interruption

in communications between the

magnetic stirrer and the wireless

controller box can be before there

is a reaction in the magnetic stirrer.

If the set time limit is exceeded,

the pre-selected temperature and

speed values become active.

Please refer to the separate in-

struction manual for the wireless

controller box for more details.

In the other menu items, the

user can enter limit values for the

temperature and speed.

•

Select “Password” from the

submenu and confirm by

pressing the rotary knob

(D).

Enter a combination of

digits as your password and

confirm by pressing the

rotary knob (D).

This information screen

informs the user that they

must confirm the hot

plate safe temperature

value when starting up the

device.

• Safety circuit confirmation

at device start-up: the hot

plate safe temperature

value must be confirmed by pressing the rotary knob (D).

pH measurement

The device has an integrated pH measuring feature for

determining the pH of different liquids.

The pH sensor must be calibrated before being used to attempt a

pH measurement.

The calibration is used to adjust the pH probe and the device

so that they work together correctly. As part of the process,

the neutral and pH gradient are specified for the measurement

chain. To complete the calibration, use pH

4, pH5 and pH7 buffer

solutions in accordance with DIN 19266.

Note:

a pH calibration can only be carried out with an inserted

temperature sensor.

• Scroll

down to the “pH

probe” icon in the menu

• Open the submenu by

pressing the rotary knob (D)

• Open the “Calibration”

submenu and confirm by

pressing the rotary knob (D)

• Place the pH probe and

temperature sensor in the

required buffer solution.

• Once the value is stable,

confirm it by pressing the

rotary knob (D).

• Follow the instructions on

the display and place the

pH probe and temperature

sensor in the next buffer

solution.

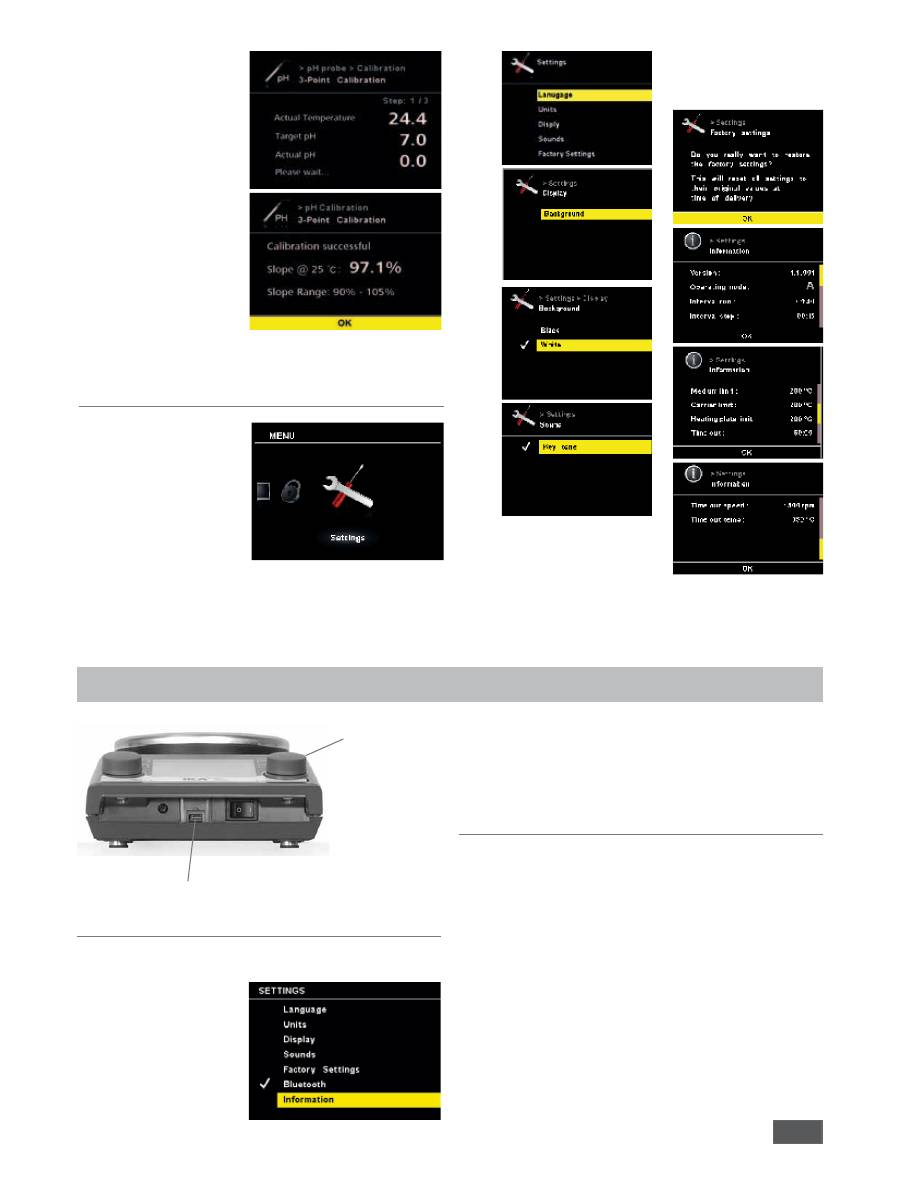

29

Confirm once more the

value displayed.

• In the case of a 3-point

calibration, a third buffer

solution must be used.

pH measurements can be

carried out once the cali-

bration has been comple-

ted successfully.

Please note:

the use of the temperature

sensor is limited by the

maximum permissible tem-

perature.

Ensure that the

temperature of the liquid does not exceed the maximum

permissible temperature.

Settings

The “Settings” menu can

be used to change how

the device operates in

accordance with the user’s

requirements.

Connections and interfaces

Micro-USB

Bluetooth

Bluetooth

The device allows the user to establish a connection to a wireless

controller box.

The device can then be

operated via a wireless

controller box within a

range of 10 m (without

obstructions).

Establishing a connection

Please refer to the separate instruction manual for the wireless

controller box for more details.

30

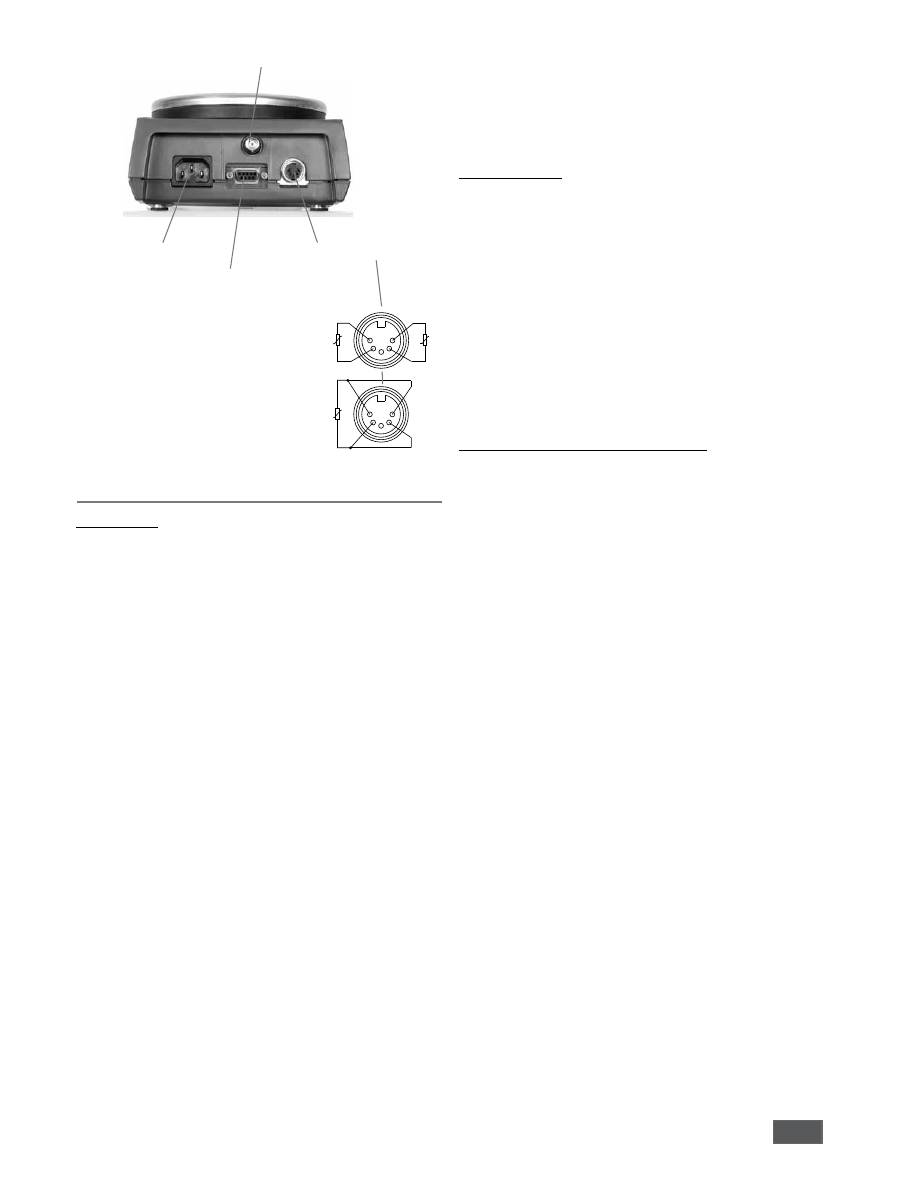

Power supply

connection

PT 100 / PT 1000 plug

RS 232

BNC connector

(only for pH probe)

Pt1000-2

5

3

1

4

2

Pt1000-1

Pt100

5

3

1

4

2

9-pin connector

Serial RS 232 interface and USB

Configuration

The RS 232 serial interface can be used to operate the device

using a computer and a suitable user program (labworldsoft).

In order to increase safety when operating the RET using a

PC, a watchdog function can be activated which monitors

the continuous data flow (see section entitled: “Watchdog

function”).

• The functions of the interface circuit between the laboratory

device and the automation system are a selection from the

signals specified in the EIA standard RS232 as per DIN 66020

Part 1. The assignment of the different signals can be seen in

the image.

• Standard RS 232, corresponding to DIN 66259 Part 1 is valid

for the electronic characteristics of the interface circuits and

assignment of signal states.

• Transmission process: asynchronous character transmission in

start-stop operation.

• Transmission type: full duplex

• Character format: character composition according to data

format in DIN 66022 for start-stop operation. 1 start bit,

7 character bits, 1 parity bit (even), 1 stop bit.

• Transmission speed: 9,600 bit/s

• Data flow control: hardware handshake RTS/CTS

RTS: (PIN 7) LOW (positive voltage)

/ COMPUTER can transmit

RTS: (PIN 7) HIGH (negative voltage)

/ COMPUTER cannot transmit

CTS: (PIN 8) LOW (positive voltage)

/ COMPUTER ready-to-receive

CTS: (PIN 8) HIGH (negative voltage)

/ COMPUTER not ready-to-receive

• Access method: data transmission from the device to the

computer only occurs after a request from the computer.

Command syntax

The following points should be noted for the instruction set:

• Commands are generally sent from the computer (master) to

the lab device (slave).

• The lab device only responds to requests from the computer.

• Commands and parameters, as well as consecutive parameters,

must be separated by at least o n e space (code: hex 0x20).

• Each individual command including parameters and data and

all responses are completed with CR LF (code: hex 0x0D and

0x0A) and can have a maximum length of 10 characters.

• The dot is used for decimal separators in a floating-point value

(code: hex 0x2E).

The details given above generally comply with the recommendations

of NAMUR (NAMUR recommendations for the design of electrical

plug-in connectors for analogue and digital signals in laboratory

MSR devices. Rev. 1.1).

Summary of available NAMUR commands

Abbreviations used:

X,y = numbering parameter (integer)

m = variable value, integer

n = variable value, floating-point number

X = 1 medium temperature(external temperature sensor)

X = 2 hot plate temperature

X = 3 hot plate safety temperature

X = 4 speed

X = 5 viscosity trend

X = 7 heat transfer medium temperature

X = 80 pH value

X = 90 Weight value

X = 54 Error 5 response time in seconds (180 <= n <= 1200)

X = 55 Intermittent mode cycle time in seconds

( 10 <= n <= 600 )

X = 56 Intermittent mode, duration of interruption in seconds

( 5 <= n <= 60 )

31

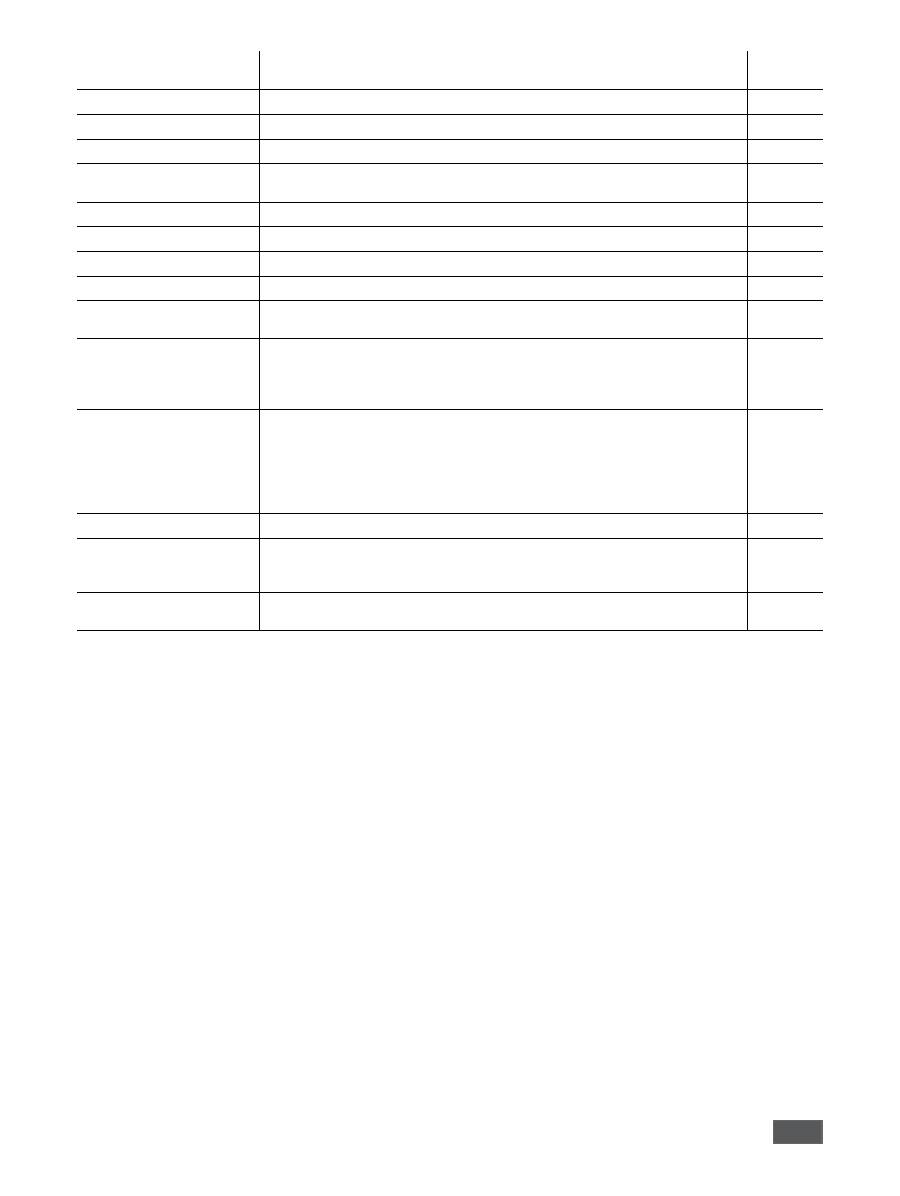

NAMUR commands

Function

Display

(additional)

IN_NAME

Title request

IN_PV_X X=1;2;3;4;5;7;80;90 Current value reading

IN_SOFTWARE

Software ID number, date, version request

IN_SP_X

X=1;2;3;4;7;8;12;

42;54;55;56;

Set target value reading

IN_TYPE

Lab device identification request

OUT_NAME name

Output of identification name. (Max. 6 characters; default: IKAMAG)

OUT_SP_12@n

Setting WD safety limit temperature with set value echo

OUT_SP_42@n

Setting WD safety limit speed with set value echo

OUT_SP_X n

X=1;2;4;7;

54;55;56

Setting of target value to n

OUT_WD1@m

Watchdog mode 1: if event WD1 should occur, the heating and stirring functions are

switched off and ER 2 is displayed. Set watchdog time to m (20 - 1,500) seconds,

with watchdog time echo. This command launches the watchdog function and must

be transmitted within the set watchdog time.

OUT_WD2@m

Watchdog mode 2: if event WD2 should occur, the speed target value is changed to

the WD safety speed limit and the temperature target value is changed to the WD

safety temperature limit value. The warning WD is displayed. The WD2 event can be

reset with OUT_WD2@0 - this also stops the watchdog function. Set watchdog time

to m (20 - 1,500) seconds, with watchdog time echo. This command launches the

watchdog function and must be transmitted within the set watchdog time.

RESET

Switches off the device function.

START_X X=1;2;4;5;7

X=80; 90

Switching on of device - (remote) function

Activation of the previous watchdog function. If no target value is entered within

60 seconds, the (old function) heating is switched off.

Remote

STOP_X X=1;2;4;5;7

X=80; 90

Switching off of device - (remote) function The variables set with OUT_SP_X remain

saved. Includes command RMP_STOP.

Remote

32

“Watchdog” functions; monitoring of the serial data flow

If, once this function has been activated (see NAMUR commands),

there is no retransmission of the command from the computer

within the set time (“watchdog time”), the heating and stirring

functions are switched off in accordance with the set “watchdog”

function or are changed to the set target values.

The data transmission may be interrupted by, for example, a crash

in the operating system, a power failure in the PC or an issue with

the connection table between the computer and REC control.

“Watchdog” - mode 1

If there is an interruption in data communications (longer than

the set watchdog time), the heating and stirring functions are

switched off and ER 2 is displayed.

“Watchdog” - mode 2

If there is an interruption in data communications (longer than

the set watchdog time), the speed target value is changed to

the WD safety speed limit and the temperature target value is

changed to the WD safety temperature limit value. The warning

WD is displayed.

Connection possibilities between the RET control

and external devices

The following adapters and adapter cables are available from

IKA

®

for connecting the RET control to external devices.

PC 1.1 cable

The PC 1.1 cable is used to connect the 9-pin plug to a computer.

Accessories

Troubleshooting

The device will indicate that there is a fault by displaying an error

message “Er X” (see table) on the screen.

Heating will be switched off permanently (exception: WD - see

table).

The stirring function continues to operate at the pre-set speed if

there is a fault in the heating circuit (exception: WD - see table).

In order to reset the device after a fault, it may need to be discon-

nected from the power supply for several seconds. The period the

device is switched off may also need to be longer if the tempera-

tures need to be counterbalanced (residual heat display may no

longer be active; see “Residual heat display”).

The safety circuit test takes place within 20 seconds of switching

on the device; after the test, the other monitoring functions are

activated.

If a fault cannot be eliminated directly, you must perform a

RESET

(see “Settings” menu)

. If the faults still cannot be elimi-

nated, the appliance must be inspected by a technical service

technician.

• Magnetic rods:

ø 6 mm; max. length 15 mm

ø 7 mm; max. length 60 mm

ø 10 mm; max. length 80 mm

•

RS 1

Set of magnetic stirring bars

•

RSE

Stirring bar remover

•

H 1000

Beaker

1 l

•

H 1500

Beaker

1.5 l

•

H 3000

Beaker

3 l

•

H 5000

Beaker

5 l

•

H 8000

Beaker

8 l

•

H 135.3

Flask carrier

•

H 135.310

Quarter 20 ml reaction vessel

•

H 135.311

Quarter 30 ml reaction vessel

•

H 135.312

Quarter 40 ml reaction vessel

•

H 135.313

Quarter 4 ml reaction vessel

•

H 135.314

Quarter 8 ml reaction vessel

•

H 135.315

Quarter 16 ml reaction vessel

•

H 135.4

Reaction block for 100 ml round flask

•

H 135.410

Insert for 10 ml round flask

•

H 135.411

Insert for 25 ml round flask

•

H 135.412

Insert for 50 ml round flask

•

H 135.5

Reaction block for 500 ml round flask

•

H 135.510

Insert for 200 ml round flask

•

H 135.511

Insert for 250 ml round flask

•

H 135.512

Insert for 300 ml round flask

•

H 135.6

Reaction block for 1,000 ml round flask

•

H 135.610

Insert for 500 ml round flask

•

H 16 V

Support rod

•

H 16.1

Extension

•

H 38

Holding rod

•

H 44

Boss head clamp

•

PT100.50

Temperature sensor

•

PT100.51

Temperature sensor, glass coated

•

PT1000.50

Double temperature sensor

•

PT1000.51

Double temperature sensor, glass coated

for further accessories see

www.ika.com

.

1

RxD 2

TxD 3

4

GND 5

6

RTS 7

CTS 8

9

PC

1

2

3

4

5

6

7

8

9

1

2 RxD

3 TxD

4

5 GND

6

7 RTS

8 CTS

9

5

4

3

2

1

9

8

7

6

33

Error messages and troubleshooting table

Fault

Description

Causes

Effect

Solutions

Er 2

In remote operation (PC) mode

with activated watchdog func-

tion in mode 1: no commu-

nication between PC and RET

control

• PC does not transmit any data

within the set watchdog time

• Connection to PC interrupted

Heating switched off

Motor switched off

• Change watchdog time

• Transmit data from PC within set

watchdog time (OUT_WDx@m)

• Check cable and plug

Er 3

Device internal temperature

exceeds 80°C

• Heat accumulation between

heating plate and housing

• Permitted ambient temperature

exceeded

Heating switched off

• Switch device off, leave to cool

and switch on again

• Change experiment

• Observe maximum permissible

ambient temperature

Er 4

Difference between target and

actual speed exceeds 300 rpm

• Motor blocked or overloaded

Heating switched off

Motor switched off

• Reduce load torque or use smaller

magnetic rods

• Reduce target speed

Er 5

No temperature increase in

sensor at continuous tempera-

ture difference (after approx.

3 mins)

• Sensor not in medium

• Volume of medium to be mea

-

sured too large

• Heat conductivity of medium to

be measured too low

• Heat conductivity of the vessel is

too low

• In the case of indirect heating,

the overall heat conductivity

resistance is too large

Heating switched off

• Place the sensor in the medium

• Reduce the volume of the media

• Use a carrier fluid with better heat

conductivity properties

• Replace the glass vessel with a

metal pot

Er 6

Interruption in safety circuit

• Defective connection cable

Heating switched off

• Replace cable

Er 13

SAFE TEMP P adjustable safety

circuit defective

• Target/current different of the

adjustable safety circuit for mini-

mum temperature monitoring

Heating switched off

• After switching on, change the

SAFE TEMP to a different value; if

this solves the issue, the previous

value can be reset by switching

the device off and on again

Er 14

Short circuit in temperature

sensor 1

• Short circuit in temperature sen

-

sor plug

• Short circuit in the cable or tem

-

perature sensor

Heating switched off

• Check the plug

• Replace the temperature sensor

Er 21

Fault during heating plate sa-

fety test

• Safety relay does not open

Heating switched off

• Switch device off, leave to cool

and switch on again

Er 22

Fault during heating plate sa-

fety test

• S_CHECK cannot generate

H_S_TEMP

Heating switched off

• Switch device off, leave to cool

and switch on again

Er 24

The temperature of the heating

plate exceeds SAFE TEMP H

(Hotplate)

• SAFE TEMP H (Probe) has been

set to lower than the current

temperature of the heating plate

• Disconnection of heating plate

control temperature sensor

Heating switched off

• Leave the heating plate to cool

• Set the SAFE TEMP H (Hotplate)

higher

Er 25

Heating switching element

monitoring

• Heater control circuit switch

(TRIAC) short-circuited

• Safety relay has interrupted the

heating circuit

• Heater or the supply line is dis

-

connected

• Interruption in heating plate

safety temperature sensor

Heating switched off

• Switch device off, leave to cool

and switch on again

Er 26

Difference between internal

heating plate control and safe-

ty temperature sensor too large

• Irregular temperature distribu

-

tion across heating plate due to

sporadic heat dissipation

• Defective control or safety tem

-

perature sensor

Heating switched off

• Switch device off, leave to cool

and switch on again

• Ensure regular heat dissipation

when using metal blocks, etc.

on the flat surface of the heating

plate

Er 31

Defective monitoring of the

heating control circuit (TRIAC)

Heating switched off

• Contact customer service

Er 41

Bar breakaway

• The bar has broken away four

times in a row without an explicit

change in the target value

Target speed reduced

by at least 300 rpm

Heating switched off

• Select a lower target speed

• Select a smaller stirring bar

34

Maintenance and cleaning

The device should operate without the need for maintenance,

however it is subject to natural wear and tear on parts and their

statistical failure rate.

Cleaning

Remove the device from the mains

before cleaning.

Only use cleaning materials recommended by

IKA

®

.

Dirt

Cleaning agent

Dyes

Isopropyl alcohol

Building materials

Water containing detergent/isopropyl alcohol

Cosmetics

Water containing detergent/isopropyl alcohol

Food

Water containing detergent

Fuels

Water containing detergent

- Ensure no liquid enters the device during cleaning.

- Wear protective gloves when cleaning the device.

- Please consult with

IKA

®

before using any cleaning or decon-

tamination methods not specifically recommended.

Ordering spare parts

When ordering spare parts, please make sure to indicate the fol-

lowing:

- device type

- device manufacturing number; see rating plate

- software version (second value displayed when switching on

the device)

- position number and description of spare part; see

www.ika.

com

.

Repairs

Please only send devices in for repair that have been

cleaned and are free of materials which might present

health hazards.

For this, use the “

certificate of compliance

” form which you can

obtain from

IKA

®

or can download a version for printing from the

IKA

®

website at

www.ika.com

.

If your appliance requires repair, return it in its original packaging.

Storage packaging is not sufficient when sending the device - also

use appropriate transport packaging.

35

Technical data

Rated voltage

V AC

220 - 230±10%

or

V AC

115±10%

or

V AC

100±10%

Frequency

Hz

50/60

Display

TFT

Timer

h

99 h 59 min 59 sec

Stirring

Motor:

ball bearing mounted, brushless EC motor

Max. motor power consumption

W

22

Max. motor output

W

12

Speed range

rpm

0; 50 to 1,700

Target speed setting resolution

rpm

1

Actual speed display resolution

rpm

1

Speed variation

%

2

(without load, 115/230 V, at 1,700 rpm, RT 25 °C)

Stirring capacity (H

2

O)

l

20

Heating

Heating plate material

Stainless steel 1.4301

Heating plate diameter

mm

135

Heat output (100/115/230 V)

W

600±5%

Temperature range

°C

RT - 340

Target temperature setting resolution

K

0.1

Actual temperature display resolution

- of the medium temperature

K

0.1

- of the carrier fluid temperature

K

1

Adjustable heating plate safety circuit

°C

50 - 380 (±5°C)

Safety circuit setting resolution

K

1

Temperature sensor in medium

PT 100 or 2xPT 1000, DIN EN 60751 Class A

Temperature sensor deviation

K

<=±

[

0.15 + 0.002°(T)

]

(PT 100 or 2xPT 1000, DIN EN 60751 Class A)

Deviation in section of temperature measurements

K

<=±0.3 < 100°C

K

<=±0.5 > 100°C

Deviation in section of temperature measurements + sensor

K

<=±0.45 at 0°C

K

<=±0.85 at 100°C

Deviation in heating plate temperature

K

±3 without vessel; heating plate at 100°C

Control hysteresis with temperature sensor

K

±0.2

(500 ml water, 600 ml glass beaker,

30 mm bar, 800 rpm, PT 100.50, 50°C)

Heating plate control hysteresis

K

±3 without vessel; heating plate at 100°C

Permissible ambient temperature

°C

+5 to +40

Permissible relative humidity

%

80

Permissible operating time

%

100

Protection class according to DIN EN 60529

IP 42

Weighing range

g

0 - 5,000

Weighing range tolerance

g

< 500: ±1

> 500: ±5

Level of contamination

2

Overvoltage category

II

Protection class

1 (protective earth)

Use above sea level

m

max. 2,000

Dimensions (W x D x H)

mm

160 x 270 x 85

Weight

kg

2.7

Subject to technical changes

36

FR

Table des matières

Page

Éléments de commande et écran

2

Table des matières

36

Déclaration de conformité CE

36

Garantie

36

Explication des symboles

36

Consignes de sécurité

37

Déballage

38

Utilisation conforme

38

Montage de la tige du trépied

38

Réglage de la limite de la température de sécurité

38

Explication des symboles

DANGER

PRUDENCE

AVERTISSEMENT

Le présent symbole signale des informations

cruciales pour votre sécurité et votre santé

. Le non-res-

pect de ces indications peut nuire à la santé et causer des blessures.

Le présent symbole signale des informations importantes

pour le bon fonctionnement technique de

l’appareil

.

Le non-respect de ces indications peut endommager l’appareil.

Le présent symbole signale des informations

importantes pour le bon fonctionnement de l’appa-

reil et pour sa manipulation

.

Le non-respect peut avoir pour conséquence des résultats de mesure

imprécis.

ATTENTION - remarque sur une mise en danger en raison du magnétisme.

DANGER - Remarque sur une mise en danger en raison d’une surface chaude.

Avertissement de danger générique.

ATTENTION

DANGER

Déclaration de conformité CE

Nous déclarons sous notre seule responsabilité que ce produit est conforme aux réglementations des directives 2006/95/CE et

2004/108/CE et est en parfait accord avec les normes et documents normatifs suivants :

DIN EN IEC 61010-1, -2-010, -2-051 et DIN EN IEC 61326-1.

Garantie

Conformément aux conditions de vente et de livraison d’

IKA

®

, la garantie a une durée de 24 mois. En cas de demande de garantie,

s’adresser au distributeur ou expédier l’appareil accompagné de la facture et de la raison de la réclamation directement à notre usine.

Les frais de port sont à la charge du client.

La garantie ne s’étend pas aux pièces d’usure et n’est pas valable pour les erreurs causées par une manipulation non conforme, un en-

tretien et une maintenance insuffisants ou le non-respect des instructions du présent mode d’emploi.

Utilisation

39

Réglage des modes d’exploitation

39

Fonctions

40

Ports et interfaces

45

Accessoires

48

Défauts

48

Entretien et nettoyage

50

Caractéristiques techniques

51

37

>100 mm

>100 mm

>100 mm

Consignes de sécurité

•

Lire entièrement le mode d’emploi avant la mise en service

et respecter les consignes de sécurité.

• Conserver le mode d’emploi de manière à ce qu’il soit accessible à

tous.

Indications générales

•

Veiller à ce que seul un personnel formé travaille avec l’appareil.

• Respecter les consignes de sécurité, les directives, ainsi que les

mesures de prévention des accidents.

•

La prise doit être mise à la terre (contact à conducteur de protection).

Attention - magnétisme !

Tenir compte des effets du champ magné-

tique (pacemaker, support de données...).

Risque de brûlure !

Toucher prudemment les pièces du loge

ment et la plaque chauffante. La plaque

chauffante peut atteindre une chaleur supérieure à 320 °C. Atten-

tion à la chaleur résiduelle après la mise hors tension!

L’appareil doit être transporté à froid !

Installation de l’appareil

N’utilisez pas

l’appareil dans des atmos-

phères explosives, avec des matières dan-

gereuses et sous l’eau.

• Placez l’appareil à un endroit dégagé sur une surface plane, stable,

propre, non glissante, sèche et non inflammable.

• Les pieds de l’appareil doivent être propres et ne pas être abîmés.

• Le câble secteur et les câbles des sondes externes ne doivent pas

entrer en contact avec la plaque d’appui chauffante.

• Avant chaque utilisation, contrôlez l’état de l’appareil et des

accessoires. N’utilisez pas de pièces endommagées.

Milieux autorisés/Impuretés/ Réactions

Attention!

Avec cet appareil, ne peu-

vent être traités et chauffés que des

agents dont le point d’inflammation dé-

passe la température de sécurité limite

(50 ... 380 °C).

La limite de température de sécurité fixée doit toujours être au

moins de 25 °C inférieure au point d’inflammation de l’agent utilisé.

Attention aux risques suivants :

- Des matériaux inflammables

- Des milieux combustibles à faible pression de vapeur

- bris de verre

- dimensionnement du récipient erroné

- niveau de remplissage du milieu trop élevé

- état du récipient non stable.

• Ne traitez des substances pathogènes que dans des récipients fer

-

més et sous une hotte d’aspiration adaptée. En cas de questions,

contactez

IKA

®

.

Ne traitez que des substances pour lesquel-

les l’apport d’énergie pendant l’opération

ne pose pas problème. Ceci s’applique

également aux autres apports d’énergie, par ex. la radiation lu-

mineuse.

• En cas de vitesses de rotation élevées, la plaque de composants

peut s’échauffer même sans chauffage par l’aimant d’entraîne

-

ment.

• Attention aux salissures et réactions chimiques éventuelles non

souhaitées.

•

Éventuellement, des particules d’abrasion provenant de l’appareil ou

des pièces en rotation puissent se retrouver dans le milieu à traiter.

• En cas d’utilisation de barreaux aimantés revêtu, tenir compte de

ce qui suit :

Les réactions chimiques du PTFE se produisent au

contact avec des métaux alcalins et alcalino-terreux fondus ou

dissous ainsi qu’avec des poudres fines des métaux du 2ème et

3ème groupe du système périodique à des températures supé-

rieures à 300-400 °C. Seul le fluor élémentaire, le trifluorure de

ATTENTION

DANGER

chlore et les métaux alcalins l’affectent; les hydrocarbures halo-

gènes ont un effet de gonflement réversible

.

Source : Römpps Chemie-Lexikon et « Ullmann » Vers.

19)

• En cas d’utilisation des métaux alcalins et alcalino-terreux dissous

et à des températures supérieures à 250 °C, il est essentielle de

n’utiliser que de barreaux aimantés !

Réalisations des essais

Portez

l’équipement de protection per-

sonnel en fonction de la classe de danger

de la substance à traiter. Sinon, il y a dan-

ger de :

- Pulvérisation et évaporation de liquides

- éjection de pièces

- Libération de gaz toxiques ou inflammables.

• Réduisez la vitesse de rotation si :

- la substance est projetée hors du récipient, parce que la vitesse

de rotation est trop élevée

- le fonctionnement est irrégulier

- le récipient se déplace sur la plaque d’appui.

Accessoires

• Un travail en toute sécurité n’est garanti qu’avec les accessoires

décrits dans le chapitre «

Accessoires

».

• Ne montez d’accessoires que lorsque la fiche secteur est débran

-

chée.

• Respectez le mode d’emploi des accessoires.

• Immerger la sonde de température externe (PT1000, ETS-D ....)

dans le milieu à une profondeur d’au moins 20 mm.

• La sonde de température externe PT1000 branchée doit toujours

se trouver dans le milieu.

• Les accessoires doivent être correctement connectés de façon sûre

à l’appareil et ne doivent pas se détacher seuls. Le barycentre de la

structure doit se trouver dans la surface d’appui.

Alimentation en tension/coupure de l’appareil

• L’indication de la tension de la plaque signalétique doit coïncider

avec la tension du réseau.

• La prise de courant utilisée pour le branchement sur secteur doit

être facile d’accès.

• Il n’est possible de couper l’alimentation en courant de l’appareil

qu’en débranchant la prise secteur ou de l’appareil.

Après une interruption de l’alimentation

électrique, l’appareil redémarre automa-

tiquement en mode B.

Pour protéger l’appareil

• L’appareil ne doit être ouvert que par un spécialiste.

• Ne couvrez pas l’appareil, même pas partiellement, par exemple

avec des plaques ou des films métalliques. Le résultat est une sur-

chauffe.

• Évitez les chocs et les coups sur l’appareil ou sur les accessoires.

• Veillez à obtenir une plaque d’appui propre !

• Respecter les distances minimales entre les appareils, entre l’appa

-

reil et le mur et au-dessus de la structure (min. 800 mm).

AVERTISSEMENT

DANGER

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

DANGER

38

Déballage

• Déballage

- Déballez l’appareil avec précaution

- En cas de dommages, établissez immédiatement un constat

correspondant (poste, chemin de fer ou transporteur)

• Étendue de la livraison

- Agitateur magnétique réchauffable RET control visc

- Câble secteur

- Mode d’emploi

- Tournevis (circuit de sécurité)

- Câble USB

- Capot de protection

H104

- Barreau aimanté

IKAFLON

30

et

40

mm

- Sonde de température

PT 100.70

Utilisation conforme

Montage de la tige de trépied

Remarque :

Pour travailler avec les cuves de plus de 180 mm Ø,

veuillez utiliser la tige

de trépied H de 16 V

avec la console H 16.1.

La limite de la température de sécurité définie s’affiche en

permanence

(7

).

Réglage par défaut : env. 380 °C

Plage de réglage : 50 - 380 °C

Réglage de la limite de la température de sécurité

a

Portez l’interrupteur de l’appareil

(A)

en position ON

a

Régler la limite de la température de sécurité au point

(B)

en utilisant le tournevis fourni

i

Affichage de la valeur réglée à l’écran

La température maximale de la plaque chauffante de 340 °C Max est

au moins 10 °C inférieure à la limite de température de sécurité réglée.

Attention : La limite de température de sécurité réglée

doit toujours être au moins de 25 °C inférieure au point

d’inflammation de l’agent à traiter.

Test de fonctionnalité du disjoncteur de sécurité

a

Chauffez l’appareil à plus de 50 °C.

a

Placez la limite de la température de sécurité en butée gauche

(50 °C) Portez l’interrupteur de l’appareil (A) en position ON

i

Affichage sur l’écran Err 25

Réglage de la limite de la température de sécurité

Ne tournez pas la vis au-delà des butées gauche et droite sous

peine de détruire le potentiomètre.

• Utilisation

- Pour mélanger et / ou chauffer des liquides.

• Zone d’utilisation (uniquement en intérieur)

- Laboratoires

- Écoles

- Pharmacies

- Universités

L’appareil est adapté à une utilisation dans toutes les zones, ex-

ceptées les zones résidentielles qui sont directement raccordées à

un réseau d’alimentation basse tension alimentant des zones rési-

dentielles.

La protection des l’utilisateur n’est plus assurée si l’appareil est uti-

lisé avec des accessoires non fournis ou non recommandés par le

fabricant, ou si l’appareil est utilisé de manière non conforme, en

ne respectant pas les prescriptions du fabricant, ou si des modifi-

cations ont été effectuées sur l’appareil ou le circuit imprimé par

un tiers.

•

Enlever le bouchon fileté

(P)

• Détachez le capuchon de protection de la tige du

trépied

• Mettez la rondelle entre le boîtier et l’écrou

• Vissez la tige du trépied à la main jusqu’à la butée

• Vissez l’écrou avec une clé à fourche de 17

• Monter les accessoires avec de manchons en croix

39

Retirez le film protecteur de la plaque d’appui ! Le changement dans le menu est effectué à l’aide de la touche de menu « Back ».

Mise en

service

Agiter

Chauffer

Raccordement

du thermomètre

externe

(régulation directe

de la température

dans le milieu)

Peser

Mesure du pH

Minuteur

F

Amener l’interrupteur de l’appareil (A) en position OFF

F

Brancher le câble secteur dans la prise secteur (K)

F

Amener l’interrupteur de l’appareil (A) en position ON

a

Le mode standard A est défini (voir « modes d’exploitation »)

F

Régler la vitesse de rotation du moteur avec le bouton de commande (D)

a

La valeur réglée s’affiche à l’écran (F)

F

Démarrer la fonction d’agitation en appuyant sur le bouton de commande (D)

i

a

Le symbole (16) s’affiche quand le moteur est activé

F

Régler la limite de la température de sécurité (voir « Réglage de la limite de la température de sécurité »)

F

Régler la température de consigne avec le bouton de commande (C)

a

La valeur réglée s’affiche à l’écran (J)

F

Régler le mode de régulation de température (voir « Réglage du mode de régulation de température »)

F

Démarrer la fonction de chauffage en appuyant sur le bouton de commande (C)

La température de consigne et la température réelle s’affichent en permanence à l’écran (J) :

i

a

Lorsque le chauffage est allumé, le symbole de chauffage (4) s’affiche

Le température max. de la plaque chauffante est de 340 °C

i

a

Tant que la température de la surface d’appui dépasse 50 °C,

et la température courante de la plaque chauf-

fante s’affichent sur l’écran (J), même lorsque l’appareil est éteint

F

Amener l’interrupteur de l’appareil (A) en position OFF

F

Connecter le thermocontact de sécurité selon DIN 12878 classe 2 ou la sonde de température PT 100 (sonde indivi-

duelle et/ou sonde double PT1000) à la douille (L)

F

Amener l’interrupteur de l’appareil (A) en position ON

i

Sonde de température PT 100

a

La température réelle (5) affichée sur l’écran (J) correspond à la température

du milieu. Le symbole « échantillon » (11) s’allume.

i

Sonde de température PT 1000

a

La température réelle (5) de la sonde de température affichée sur l’écran (J) cor-

respond à la température du milieu. Le symbole « sonde de température externe »

(11) s’allume.

Dans le même temps, la température du liquide porteur (3) s’affiche.

F

Appuyer sur la touche (G)

F

attendre que le système soit stable (une fois que le système est stable, un « g » s’affiche derrière le chiffre 0.

F

Placer le poids au milieu de la plaque chauffante et attendre que le système soit stable.

i

a

La plage d’affichage maximale est de 2000 g

a

La plage de pesage maximale est de 5000 g

a

La fonction Peser peut être activée uniquement quand les fonctions Chauffer et Agiter sont désactivées

i

a

Le module de pesage peut être calibré (voir le chapitre « Étalonnage du module de pesage »)

a

Voir le chapitre « Étalonnage de la sonde pH et mesure du pH »

F

Appuyer sur la touche (H)

F

Régler le temps désiré en heures, minutes et secondes en tournant le bouton rotatif (D) et confirmer en appuyant.

Après le démarrage des fonction Chauffer ou Agiter, la fonction minuterie commence en comptant en arrière (voir

« fonction minuterie »)

i

Lorsque la minuterie atteint 0, la fonction Chauffer est toujours désactivée, même si le moteur a été démarré en premier.

Si le chauffage est activé pendant le fonctionnement de la minuterie, seulement le chauffage est désactivé, le

moteur continue de tourner (retard d’ébullition).

Utilisation

(notice)

Réglage des modes d’exploitation

Exploitation de l’appareil avec les modes A, B ou C

Réglage d’usine : Mode A

Le mode réglé s’affiche à l’écran (10) en permanence.

Mode A

Tous les valeurs définies sont conservées après l’arrêt ou le

débranchement de l’appareil. Après la mise en marche de l’appareil,

l’état des fonctions Chauffer et Agiter est désactivé (OFF).

Mode B

Tous les valeurs définies sont conservées après l’arrêt ou le

débranchement de l’appareil. Après la mise en marche de

l’appareil, l’état des fonctions Chauffer et Agiter avant le dernier

arrêt est reprise (ON ou OFF).

40

Mode C

Ce mode permet de travailler avec ou sans sonde de

température.

Après la mise en marche de l’appareil avec l’interrupteur de

l’appareil, les fonctions Agiter et Chauffer démarrent avec le

dernier état et les dernières valeurs. Les valeurs de consigne

réglées pour les modes de fonctionnement A et B ne peuvent

pas être modifiées.

Changement des modes d’exploitation

-

Faites défiler le menu jusqu’à l’icône « Mode »

-

Ouvrez le sous-menu en appuyant sur le bouton rotatif (D)

-

Sélectionnez le mode en tournant le bouton rotatif (D) et con-

firmez le mode sélectionné en appuyant sur le bouton rotatif

(D)

-

Une brève description du mode sélectionné s’affiche

-

Confirmez le mode en appuyant sur le bouton rotatif (D).

Fonctions

Le mode de régulation de la température sélectionné pendant le

fonctionnement avec PT100 est signalé par le symbole

(11)

dans l’affichage digital.

La température de consigne (2) affichée

et la température réelle (5) se réfèrent

à la température du milieu. La tempé-

rature de la plaque chauffante est limi-

tée par la température de sécurité (7)

réglée. La régulation de la température

du milieu s’effectue via un microcon-

trôleur. Cela permet de chauffer la tem-

pérature du milieu détectée par la PT

100 le plus rapidement possible et sans

dépassement à la température réglée.

Le microcontrôleur s’adapte automa-

tiquement aux différentes capacités

thermiques des différentes récipients

à poser utilisés et à leur contenu. Cela

garantit toujours une régulation opti-

male de la température sans dérive en

température et ondulation.

Réglage de la température du milieu avec la

sonde de température PT100

L’utilisateur peut personnaliser la régulation de température selon

ses besoins dans trois modes différents. Le mode de régulation de

température sélectionné s’affiche en plus du symbole (

11).

Modes de régulation

Changement des modes de

régulation

-

Faites défiler le menu

jusqu’à l’icône « Chauffer »

-

Ouvrez le sous-menu Mé-

thode de régulation en

appuyant sur le bouton

rotatif (D)

-

Sélectionnez le mode en

tournant le bouton rota-

tif (D) et confirmez le mode

sélectionné en appuyant

sur le bouton rotatif (D)

-

Une brève description du

mode sélectionné s’affiche

-

Confirmez le mode en

appuyant sur le bouton

rotatif (D).

PID

: pour les milieux très sensibles qui doivent être traités avec

prudence.

Avantage :

• chauffage très précis du

liquide

• aucun dépassement de

la température

Désavantage :

• fonctionnement de

chauffage le plus lente

T

Set

t

Fast PID:

Combine les avantages de PID et de la régulation

à 2 points

(chauffage très

rapide et de

haute précision

de régulation, les

dépassements

sont possibles).

Régulation à 2 points

:

Pour les milieux qui ne sont pas trop sensibles.

Avantage :

• Le chauffage est beau

-

coup plus rapide que le

PID

Désavantage :

• Dépassement de la

température du milieu

jusqu’à 10 °K

T

Set

t

T

Set

t