Bosch WFB 1602 – page 4

Manual for Bosch WFB 1602

Detergents and fabric-care additives

L

Fig.®,®

Frequent use of insufficient detergent will'even

You can use any standard powder or liquid de

tually become noticeable as follows:

tergent which is suitable for automatic washing

- washing appears grey or not properly clean

machines.

“ grey-brown stains (grease marks) form on

! Do not use non-automatic detergents as

the washing

these produce too much foam.

- scale builds up on the heating elements.

! Do not use solvent-based cleaning agents

Too much detergent results in:

in fully automatic washing machines. Explo

- unnecessarily high environmental pollution,

sion hazard.

- due to the generation of too much foam, the

! Do not use any detergent boosters con

washing.is hardly agitated which leads to

taining solvents or dirt and stain-removings

poor washing results.

sprays near the machine, as these could

The amount of detergent indicated on its

damage the machine.

packaging refers to a full machine load.

! Always store'detergents and other fabric-

For smaller loads or less soiling, reduce the

care products out of children's reach.

amount of detergent.

Amount of detergent

Notes

The best washing results will only be achieved

Fabric softeners and conditioners

if you add the correct amount of detergent. Ob

Put these into the ® compartment. Do not fill

serve the instructions for use shown on the de

beyond the MAX mark, otherwise they will be

tergent packaging.

flushed into the machine together with the de

When using liquid detergents, first slide the

tergent at the start of the programme. Dilute

green insert out of the back section of the de

thick conditioner with a little water (taking care

tergent drawer and slide it in at the front

to dissolve all lumps) before pouring it into the

(Fig. ®). Then add the liquid detergent.

® compartment.

The scale on the insert will help you to add the

Bleaching agents and stain removers

correct amount of detergent. Do not fill the de

In addition, certain powdered bleaching agents

tergent dispenser beyond the MAX mark.

and stain removers may be used on stained

You can also use any measuring aids provided

fabrics.

with the detergents, such as dosage balls or

First put the detergent and then the bleaching

bags.

powder or stain remover into compartment II.

The amount of detergent depends on:

— water hardness

— degree of soiling

— size of the load

— amount of detergent to be added according

to its manufacturer.

63

GB

[Preparing laundry for washing

Sorting the laundry

Practical tips

о Sort the laundry according to the symbols

O Remove any loose items or metal objects,

on the fabric care labels.

such as safety pins, paper clips, etc. from

! Knitted garments or garments with a wool

the laundry.

content can only be washed in the machine

O Brush sand out of pockets and cuffs.

if they are marked "machine-washable".

O Close zips and button up cushion covers,

Risk of shrinking.

duvet covers, etc.

O Remove curtain runners, or secure them in a

Only items marked with the following care sym

net bag.

bols are suitable for washing in the machine:

O Particularly delicate items, such as tights or

cottons

lace curtains, or smaller items, such as tiny

socks or handkerchiefs, should only be

coloureds Убо7 УЗоУ

washed in a net bag or pillow case.

easy-care

O Some items are best turned inside out.

These include knitwear, trousers, T-shirts

ХШ Ш ХШ Ш Ш

and sweatshirts.

O Make sure that wire-cup bras are machine-

machine-washable wool

washable.

Ш Ш Ш Ш

! Wash wire-cup bras in a pillow case which

can be securely closed with a zip or buttons.

If the wire works itself out of the cup it may

Laundry marked with the following care sym

fall through the holes of the drum and cause

bols must not be washed in the machine:

extensive damage.

hand wash

Stain removal

do not wash w

If possible, stains should be removed immedia

tely while they are still fresh, or at least pre

treated. Try soap and water first of all. Dab the

Sort the laundry.by colour.

material rather than rub it.

Wash white and coloured items separately

Stubborn, dried-in stains may require several

otherwise white washing will turn grey.

washes before they disappear completely.

Do not wash new coloured items together

with other laundry. Risk of discoloration!

Do not exceed the machine’s maximum

capacity when sorting the laundry. Do not

overload the washer/dryer. Overloading

leads to inferior results.

Maximum washing loads;

Cottons / coloureds 4.5 kg

Easy-care, woollens 1.5 kg

64

GB

"n

First wash cycle

Washing

Carry out the first wash cycle without laundry

Open the door

to remove any water left over from the factory

<> Pull the handle on the door towards you

tests.

(Fig.®).

1. Check that the transit bolts have been re

moved from the back of the machine (see

Put washing into the machine

installation instructions).

! Any items which have been pre-treated with

2. Turn the tap ON.

solvent-based cleaners, such as stain remo

3. Pull the detergent drawer out as far as it will

vers and petrol-based agents must be aired

go.

before they are put into the machine.

4. Pour half a measuring cup into compart

Explosion hazard!

ment II. Do not use a special detergent for

! Before loading the machine, ensure that

délicates or woollens as these will create

there are no foreign objects nor trapped

too much foam.

pets in the drum.

5. Turn the programme selector clockwise and

O Place the washing into the drum so that'it is

set it to Cottons / coloureds, normal (B).

folded out and loose, with a mixture of large

6. Set the temperature selector 90 '^C.

and small items.

7. Press the "ON/OFF" button.

Close the door

The programme is started.

! When you close the door, make sure that

8. When the programme has ended, press the

nothing is caught between the door and the

"ON/OFF" button to switch the machine off.

rubber seal.

O Close the door by pressing it shut until it

snaps into place with an audible click.

Add detergent

Turn ON the tap

65

GB

Washing End of wash programme /

Switching the machine OFF

Selecting the wash programme

All programmes end automatically after the

1, Turn the programme selector clockwise until

spin cycle.

it reaches the required programme (Fig. (§)),

If the ’’Rinse hold" button has been pressed,

2, Set the temperature selector to the required

the programme will stop at the final rinse cycle

temperature,

and the washing will be left in the final rinse

3, Press the buttons for any additional func

water.

tions that are required.

You then have two options:

• remove the washing while it is dripping-wet

Starting the programme

• spin the washing

1, Make sure that the door is closed,

If you want to take the laundry out dripping-

A safety switch prevents the machine from

wet:

operating when the door is open,

1, Switch OFF the machine,

2, Press the ’’ON/OFF” button (Fig, ®), The

2, Set the programme selector to Pumping

red ON indicator light illuminates and the

(P).

programme starts.

3, Switch the machine ON again.

Programme sequence

The rinse water is pumped out without spin

The position of the programme selector Indi

ning.

cates which stage in the wash programme the

If you want to spin the laundry;

machine is currently at.

O Press the "Rinse hold" button again to re

turn it to its normal position.

Altering the programme

The water is then pumped out and the laun

Switch off the machine (press the "ON/OFF”

dry is spun.

button). Turn the programme selector clock

wise to the new programme. Switch the ma

Switching the machine OFF

chine on again.

1. Press the ’’ON/OFF" button.

The machine is switched off and the power

indicator light goes out,

2. After approx, 2 minutes you will be able to

open the door and remove the washing.

! Remove any foreign objects (paper clips,

coins, etc.) inside the drum or trapped in the

rubber seal, otherwise there is a danger or

rust occurring.

Leave the door open slightly so that the ma

chine can dry out properly.

3. Reset any buttons that were pressed by

pressing them again.

4. Turn the tap OFF!

66

GB

Cleaning / Maintenance / Frost Protection

L

Before you begin any maintenance work,

Cleaning the pump

unplug the machine from the mains or

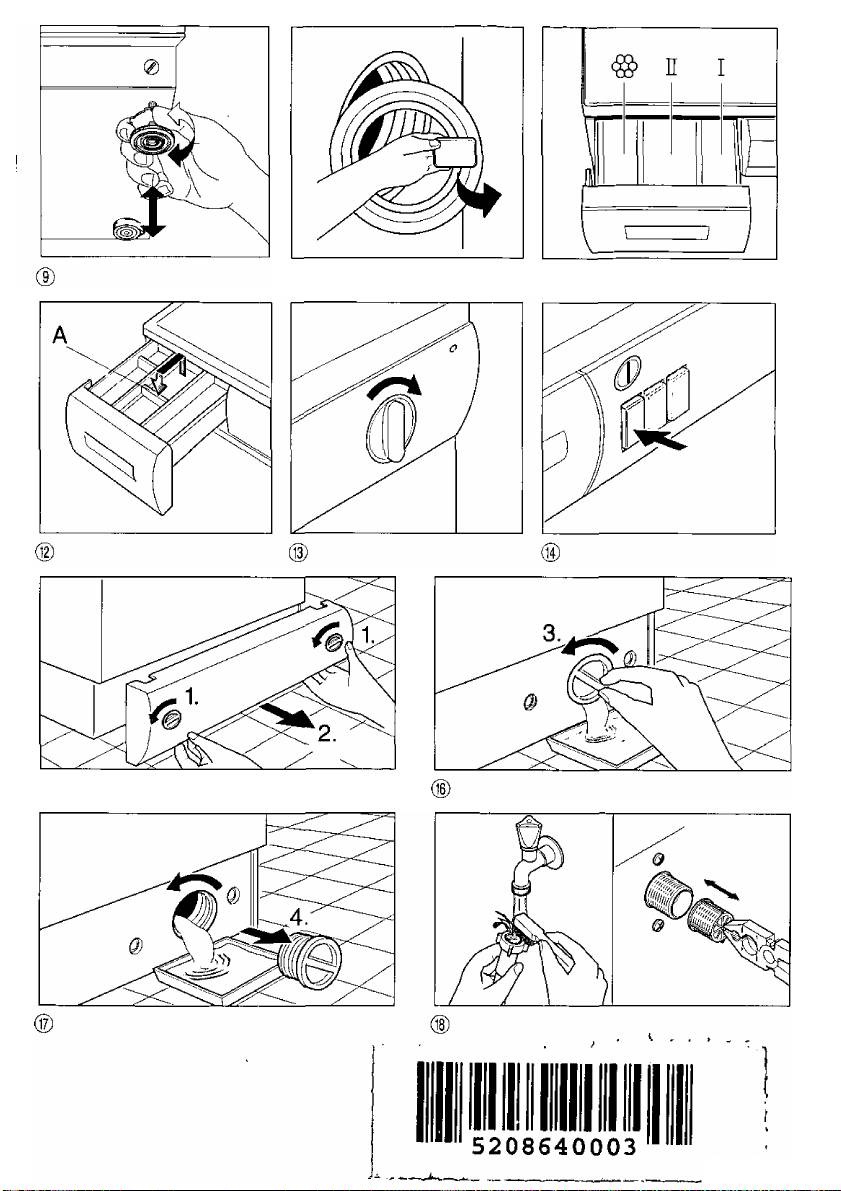

Fig.(D,(D,(g)

switch it off at the fuse-box. Turn the tap

The pump must be cleaned:

off.

• if the pump has been blocked by some for

eign object, such as a button or paper clip,

Cleaning your machine

and water cannot be pumped out.

! Do not use solvents, as these can damage

• after washing very fluffy items.

machine components, produce noxious va

Before cleaning the pump, water must be

pours and they also constitute an explosion

drained from the machine. If the pump has

hazard.

been blocked, up to 20 litres of water can run

! Do not spray the machine with a jet of water.

out - so keep a bucket handy.

Housing and fascia panel should only be clea

Cleaning procedure:

ned with detergent solution or with a standard,

1. Remove the base panel from the front of

solvent-free, non-scouring cleaning agent.

the machine,

Cleaning the detergent drawer

! Scalding hazard. Allow hot water to cool

1. Pull the detergent drawer all the way out of

down.

the machine (tug slightly to overcome the

2. Carefully unscrew the pump cover - do not

spring catch).

remove it completely - and let the water

2. Clean all parts under running water.

drain out into a shallow container (let the

remainder drip onto a floor cloth),

3. Replace the detergent drawer in the ma

chine.

3. Remove the pump cover.

4. Remove any foreign objects and fibrous

Descaling the machine

deposits. Clean the inside of the pump. En

If you use the right amount of detergent, it will

sure that the vanes on the pump move

not normally be necessary to descale the ma

freely.

chine.

5. Screw the pump cover back on.

! Descaling agents contain acids which can

corrode machine components and cause

6. Replace and close the base panel.

discoloration of laundry.

7. Pour approx. 2 litres of water into the deter

However, if you do want to descale your

gent drawer and start the Pumping pro

washing machine, follow the manufacturer's

gramme (P). This prevents detergent from

directions.

passing unused straight out into the drains

the next time that the washing machine is

Cleaning the drum

used.

Any rust caused by metal objects left in the

machine must be removed using a chlorine-

free cleaning agent (check the description of

contents on the pack). Do not use steel wool!

Water inlet hose

To avoid water damage, arrange for the hose to

be checked by a specialist every 5 years.

67

GB

Cleaning / Maintenance / Frost protection

Cleaning the filters in the water inlet

Frost protection

Fig.®

If the machine is located in a room which is

The filters in the water inlet must be cleaned if

exposed to freezing temperatures, any residual

no or insufficient water flows into the machine

water in both the pump and the water inlet

when the tap is turned ON.

hose must be drained immediately every time

The filters are located in the hose connection at

the machine is used.

the tap end and at the back of the machine.

Draining the pump:

Cleaning procedure:

See "Cleaning the pump" on page 67.

1. Turn off the tap.

Draining the water Inlet hose:

1. Turn the tap OFF.

2. Set the programme selector to Cottons /

coloureds, normal (B) and the tempera

2. Unscrew the hose from the tap and hold

ture selector to 0. Press the "ON/OFF" but

the end of the hose over a container.

ton.

3. Switch ON any of the wash programmes for

After approx. 40 seconds, switch off the

approximately 40 seconds. Water left inside

machine by pressing the "ON/OFF” button

the inlet hose will be drained out.

again.

4. Screw the hose back onto the tap.

This removes the pressure inside the inlet

hose.

3. Unscrew the hose from the tap and rinse

the filter under running water.

4. Screw the hose back onto the tap.

5. Unscrew the hose at the back of the ma

chine.

6. Use a pair of flat-nosed pliers to remove the

filter. Clean the filterand replace it inside

the hose connection,

7. Reconnect the hose.

8. Turn on the tap and make sure that no wa

ter leaks at either end of the hose.

9. Turn off the tap.

68

GB

I Correcting minor problems yourself

! Only qualified technicians are permitted to repair electrical appliances. Repairs by unauthorised

persons can lead to considerable damage.

Problems

Possible causes / remedies

The power indicator iight

-The plug is not correctly, or only loosely, inserted into the

does not come on

socket.

- A fuse has blown in the domestic wiring.

- Power failure.

Power faiiure

If there is a power failure or the machine malfunctions, there is a

special procedure for emptying the machine of water (see

"Cleaning the pump”, page 67), so that the laundry can be re

moved.

Washing sequence does not

"ON/OFF" button not pressed.

start

Door not properly closed.

No water to be seen during

This is not a malfunction! The water inside the machine is below

washing

the level at which it becomes visible.

Poor washing resuits

Degree of soiling was greater than usual.

Change type and amount of detergent.

Select maximum permissible temperature for fabric type.

Select a more powerful wash programme.

Foam comes out of the

Too much detergent was used. Switch off the machine for ap

detergent drawer

proximately 5-10 minutes. To reduce the amount'of foam, put a

tables poon of fabric softener mixed with 1/2 litre water into the

detergent drawer. For the next wash, adjust the amount of deter

gent accordingly.

Foam stiii visibie after iast

Certain detergents tend to produce more suds but this does not

rinse

affect the rinsing result.

Motor noise

This is not a malfunction! It is normal for noises to be heard while

the motor is running in.

Pump noise

This is not a malfunction! It is norma) for noises to be heard from

the pump during the start-up phase or the final stage of draining

the drum.

j Vibrations when washing

- Transit bolts were not removed. Follow the directions in the

and spinning

installation instructions (page 71).

- The machine’s feet were not secured in place when the ma

chine was installed. Realign the machine using a spirit level,

.securing the machine's feet according to the installation in

structions.

Machine does not spin or

Pump blocked

does not pump out the water

69

GB

[Customer service

__

J [technical specifications

о Before calling Customer Service, see if you

Width .

59.5 cm

can correct the problem yourself. (To do

Height,

85.0 cm

this, refer to "Correcting minor problems

Depth

56.0 cm

yourself”).

Weight

approx. 70 kg

If a service engineer is called out and no

Capacity

fault is found with the machine, a call-out.

Mains voltage

see rating plate

charge will be made, even if the machine is

Connected load

stilt under warranty.

Fuse rating

Water pressure

1 - 10 bar

! If you can't correct a problem yourself,

switch off the washing machine, remove the

plug from the socket, shut off the water sup

ply and call Customer Service.

Customer Service will ask you for the ma

chine’s product number (E-Nr.) and serial num

ber (FD). These numbers are shown on the ra

ting plate which can be found on the frame of

the open door and also on the identification

plate, enclosed by a thick line, on the front of

the machine behind the base plate.

Make a note of your machine’s numbers here:

r

E-Nr. FD

Product n

umber Serial nu mber

Please help to avoid unnecessary travel by our

Customer Service engineers by providing the

correct product and serial numbers. You will

also save the additional costs which would

otherwise occur.

70

GB

I Removing the transit bolts

■ Installing the machine

_______

^

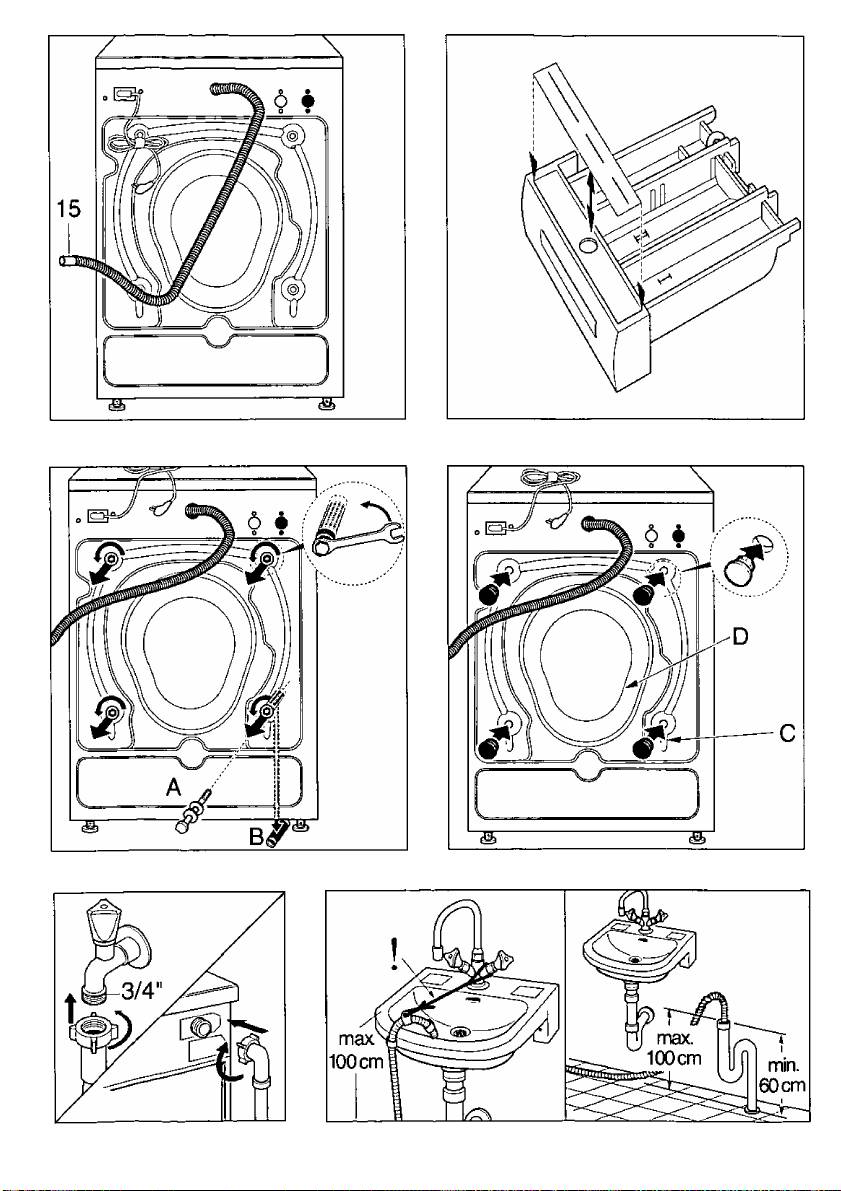

Fig,®.®

! When installing and connecting the ma

! Before the machine is used for the first time,

chine, special attention must be paid to the

it is very important that the transit bolts are

safety advice and warnings which have

removed from the back of the machine,

been identified with an exclamation mark

! Only use the spanner supplied with the ma

You should comply with all regulations

chine if a ring spanner is unavailable.

issued by your local water and power autho

! Caution. If the spanner slips, there is danger

rities.

of injury.

! Take care when lifting the machine! Risk of

1. Undo and remove the 4 securing bolts (A).

injury.

2. Remove the four spacers (B) that will have

! Do not lift the machine by any of the pro

dropped down inside the machine. Tilt the

truding parts.

machine to the rear so that they fall out.

! If in doubt, arrange for the machine to be

3. Insert the cover caps (C) which you will find

connected by a qualified specialist.

in the bag containing the documentation,

Before leaving the factory, every machine is

! Keep the transit bolts in case you need to

thoroughly tested under operating conditions.

move the machine again (moving house).

Any moisture or residual water which you may

Do not transport the machine without first

find in the machine or drain hose is left over

inserting the transit bolts. To do this, un

from these tests.

screw the back panel D and proceed in re

Installation location

verse order (1 and 2 above).

To ensure'that the machine remains stable

while it is spinning, the installation location

must be flat and solid.

Do not site the machine on soft floor coverings

such as vinyls, carpeting or foam-backed carpets.

! In the case of timber beam floors, place

the machine on a water-resistant wooden

board that is at least 30 mm thick and is

screwed to the floor. If possible, the ma

chine should be sited in the corner of a

room.

Secure the machine by attaching retaining

straps to the feet (this applies particularly if

a dryer is going to be placed on top of the

washing machine).

! If the machine is installed on a plinth, the

machine’s feet must be secured with retain

ing straps to prevent it sliding while it is

spinning.

Retaining straps are available as a set from

your authorised dealer.

71

GB

Aligning the machine

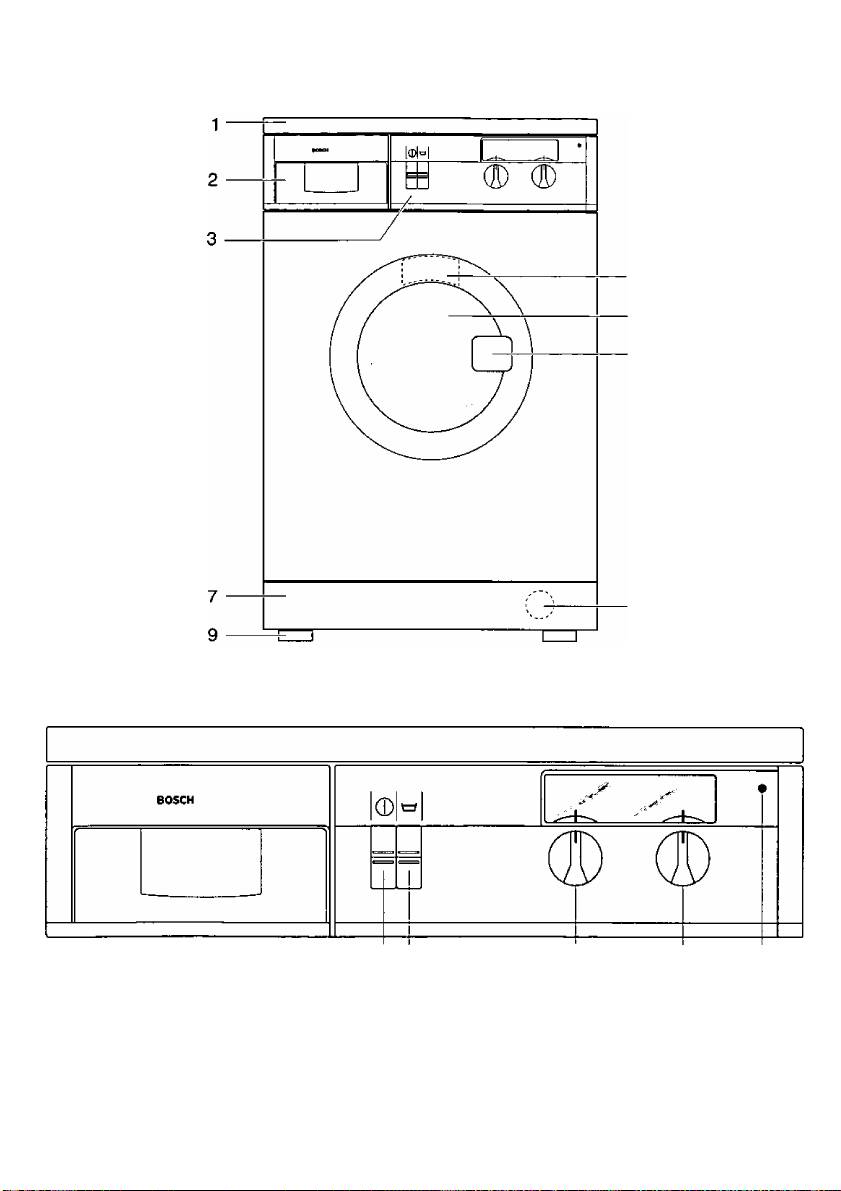

Fig. (D

Fig. ®

! The machine must be perfectly level with all

For the water connection, a standard cold-wa

four feet standing on the floor. It must not

ter line with a minimum water pressure of 1 bar

wobble.

is required (with tap full ON, at least 8 litres of

O Use a spirit level to align the machine on all

water must flow out in one minute).

If the water pressure exceeds 10 bar, a pres

sides.

If necessary, correct the height of the ma

sure reducing valve must be added.

chine’s feet.

! Do not connect the machine to the mixer tap

1. Undo the lock nuts

on a pressuretess hot-water heater. If in

doubt, arrange for the machine to be con

2. Adjust the height of the feet.

nected by a specialist.

3. Tighten the lock nuts again firmly to ensure

! Caution! The hose connections are subject

that the feet remain at the same height.

to the full water pressure; check for leaks

with the tap turned fully ON.

! The filters at the free end of the inlet hose

and at the back of the machine should only

be removed for cleaning purposes.

! To avoid water damage, the tap must be

turned OFF when the machine is not in use.

Í The plastic nuts on the hose connections

should only be tightened by hand.

72

ф

10 11 12

13 14

CD